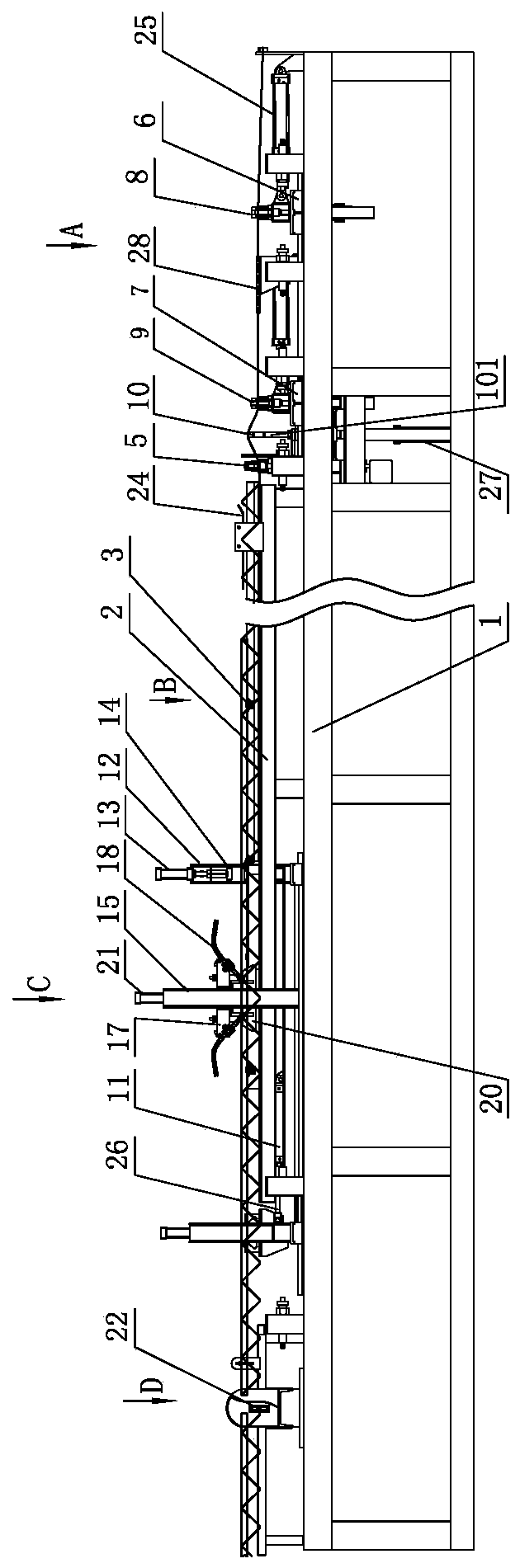

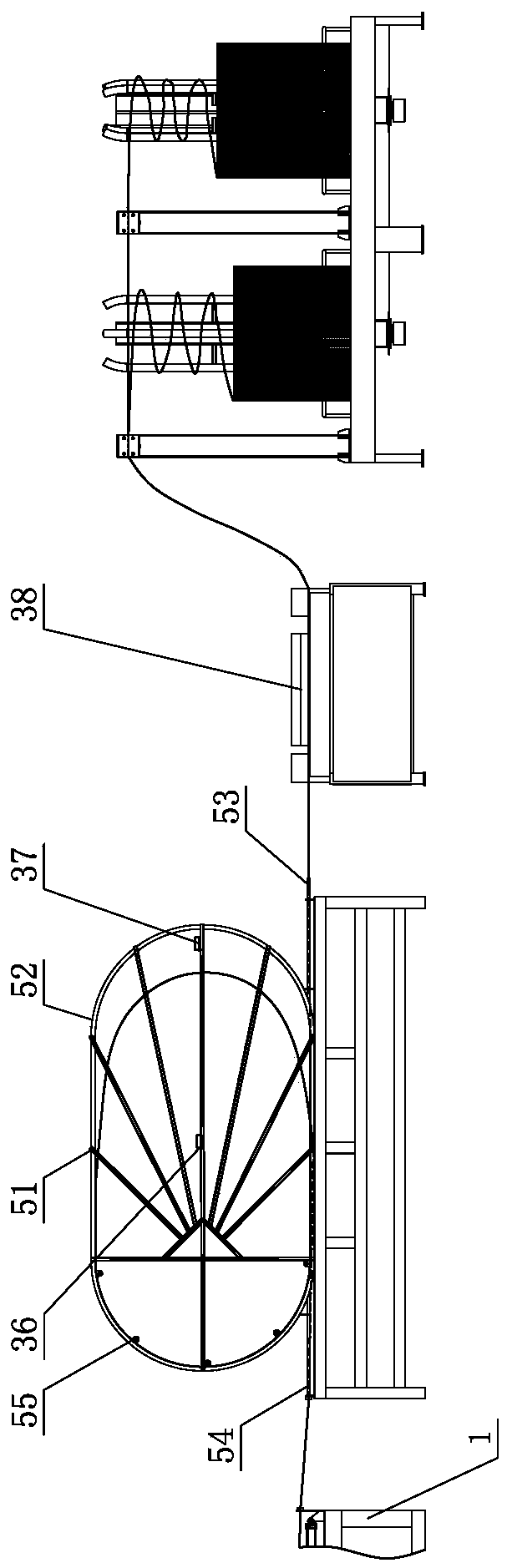

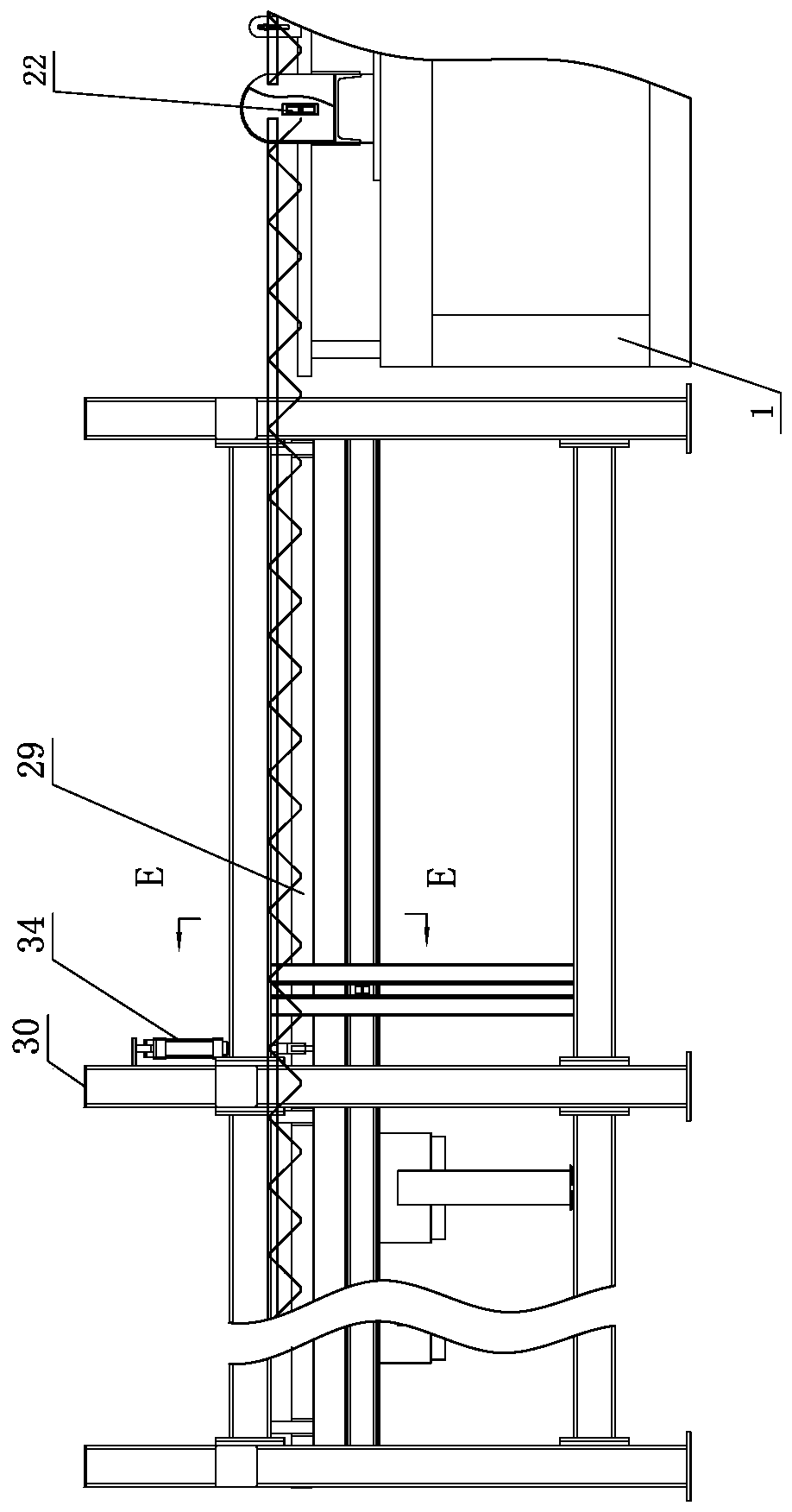

Steel pipe truss production line

A steel pipe truss and production line technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of lack of mechanized production conditions, loss of supporting force, etc., to facilitate continuous and efficient production, and low leakage welding rate , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The steel pipe truss production line of the present invention comprises a frame 1, a steel pipe support 2 is installed on the frame 1, a plurality of steel pipe supporting wheels 3 are installed on the steel pipe support 2, steel bar guide grooves 4 are arranged on both sides of the steel pipe support 2 in the length direction, steel pipe support 2 One end is provided with steel bar bending and forming equipment 101, and the side of steel bar bending and forming equipment 101 away from the steel pipe support 2 is provided with a first slider 6, the first slider 6 is connected with the piston rod of the steel bar feeding cylinder 25 and can be placed in the steel bar feeding cylinder Driven by 25, it moves along the length direction of the frame 1, the first double-headed pneumatic steel bar clamp 8 is installed on the first slider 6, the movable frame 11 is installed on the frame 1, and the movable frame 11 is connected with the piston rod of the steel pipe drive cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com