Pultrusion part for wind power blade, perfusion method of wind power blade and wind power blade

A technology for wind power blades and blades, applied in household components, applications, household appliances, etc., can solve problems such as perfusion, and achieve the effect of increasing the bonding area, improving the perfusion effect, and reducing the risk of reverse wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

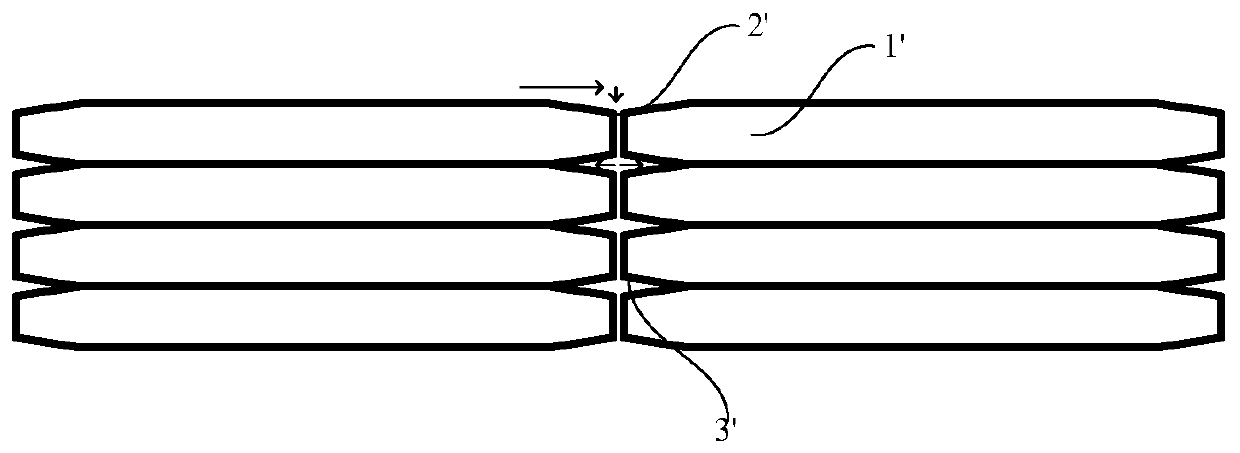

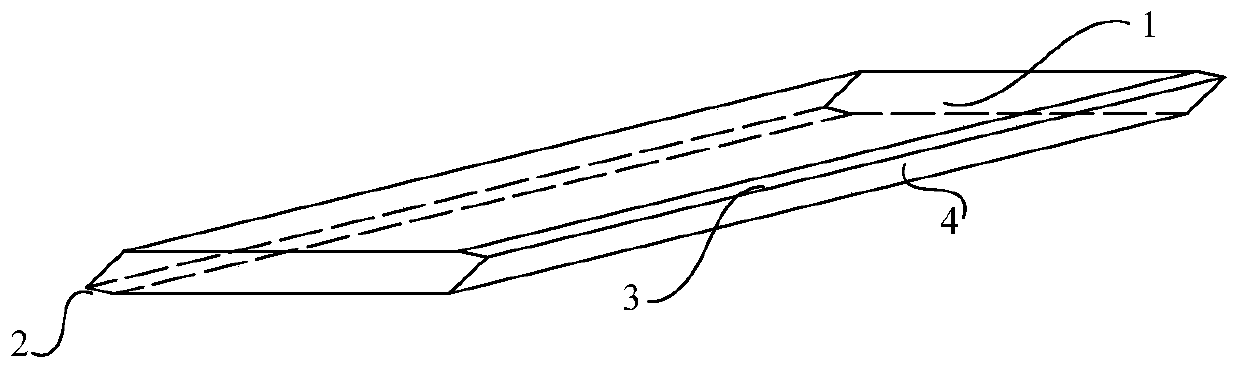

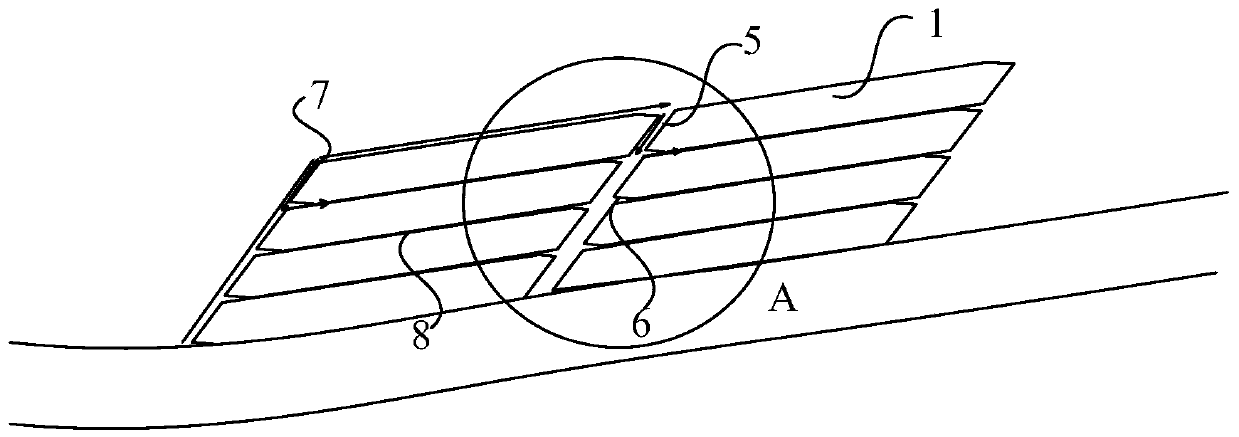

[0042] Such as figure 2 , image 3 As shown, the pultruded part 1 of the present invention is a prism, and the cross-section in the thickness direction of the pultruded part 1 is a parallelogram. The upper right corner and the lower left corner are acute angles, and there are chamfers 2 at the acute corners of the parallelogram. The chamfering at the acute corners can ensure that the receiving platform 6 is better formed when the resin is poured later. As an alternative, there may be no chamfer 2 at the acute corners of the parallelogram. In order to better pour the pultruded part 1 , the pultruded part has a splicing surface 4 , and the part of the splicing surface 4 corresponding to the acute angle has an inclined surface 3 . Preferably, the splicing surface 4 is two opposite surfaces.

[0043] Through the pultruded parts with parallelogram section, and ensure that the adjacent splicing surfaces are parallel and the stacked surfaces are on the same plane, the weak throug...

Embodiment 2

[0052] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that in order to make wind power blades, step S2 may also include: stacking the pultruded part 1 in the blade mold, and laying layers and core materials in the blade mold ; After the step S3, the following steps may also be included: through the vacuum infusion process, the pultrusion, the layup and the core material are integrally infused and solidified to form the whole blade shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com