Modularized underwater robot vector propulsion mechanism

A technology for underwater robots and vector propulsion, which is applied to propulsion components, ship propulsion, underwater ships, etc., and can solve problems such as complex structures, heavy weight, and small angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

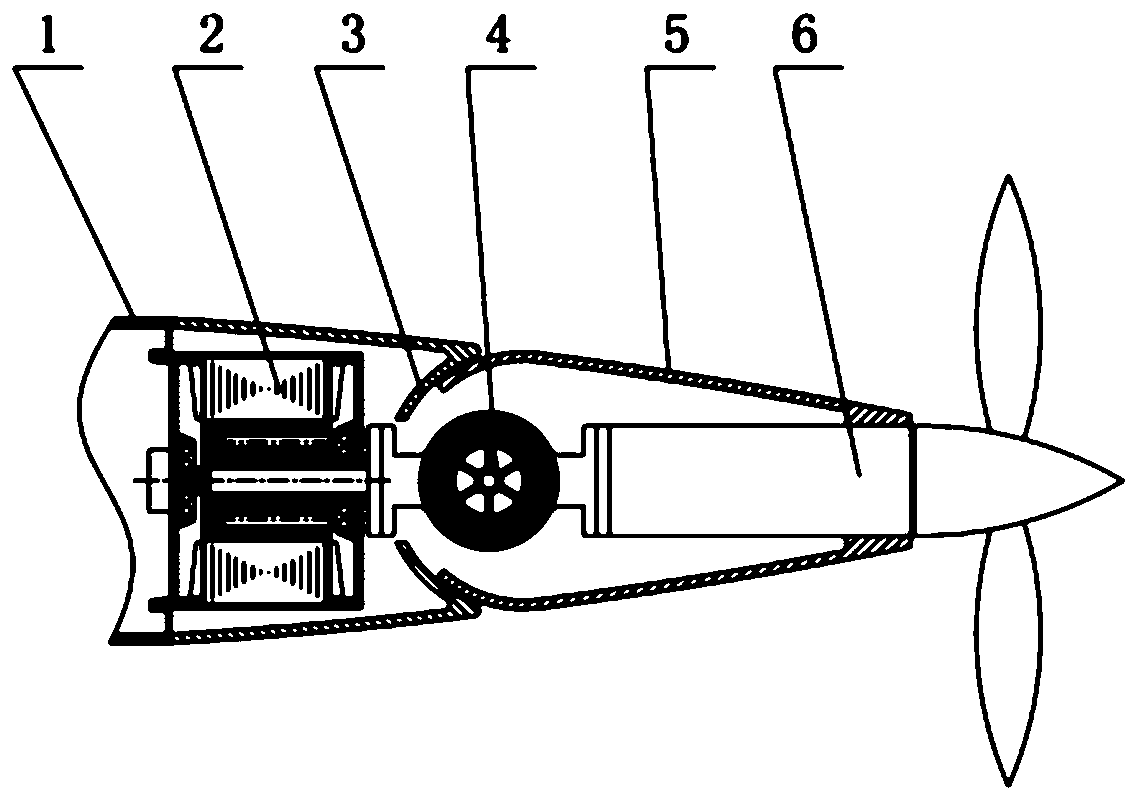

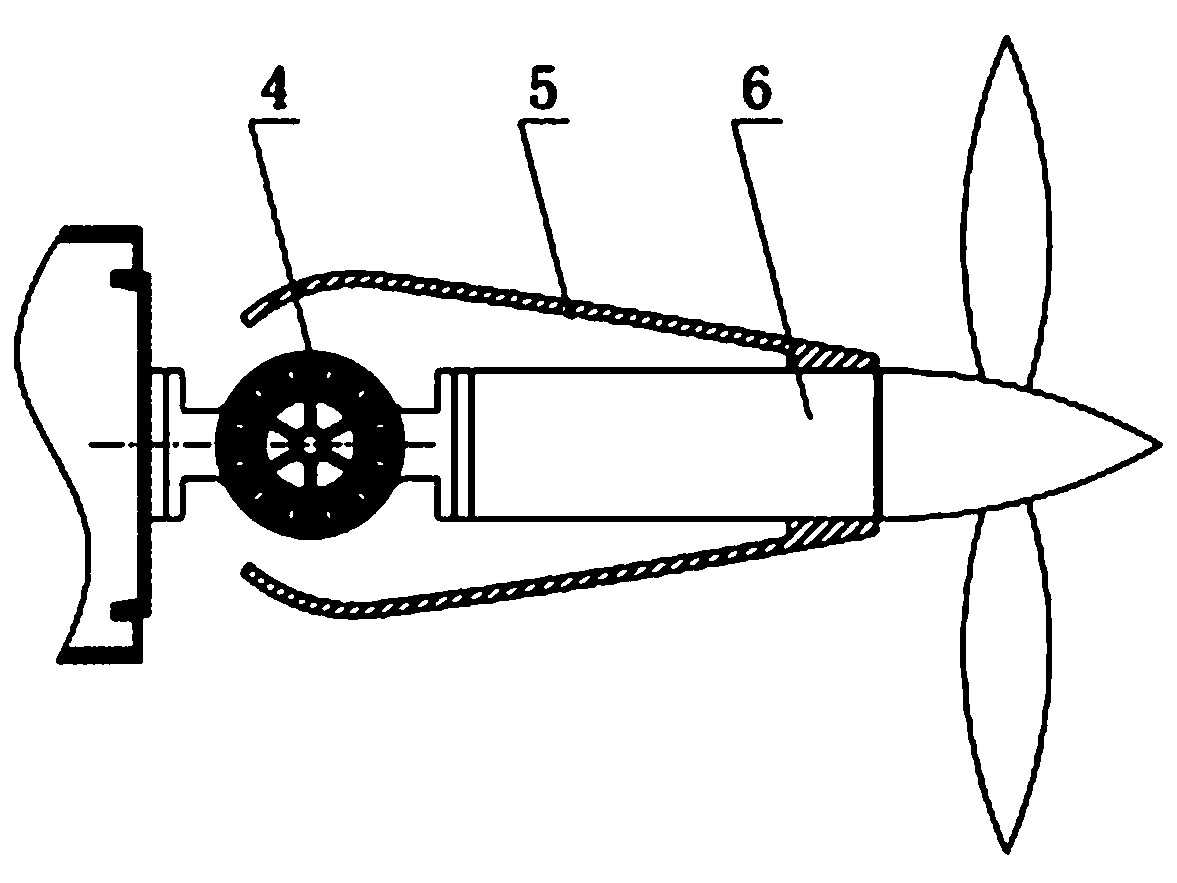

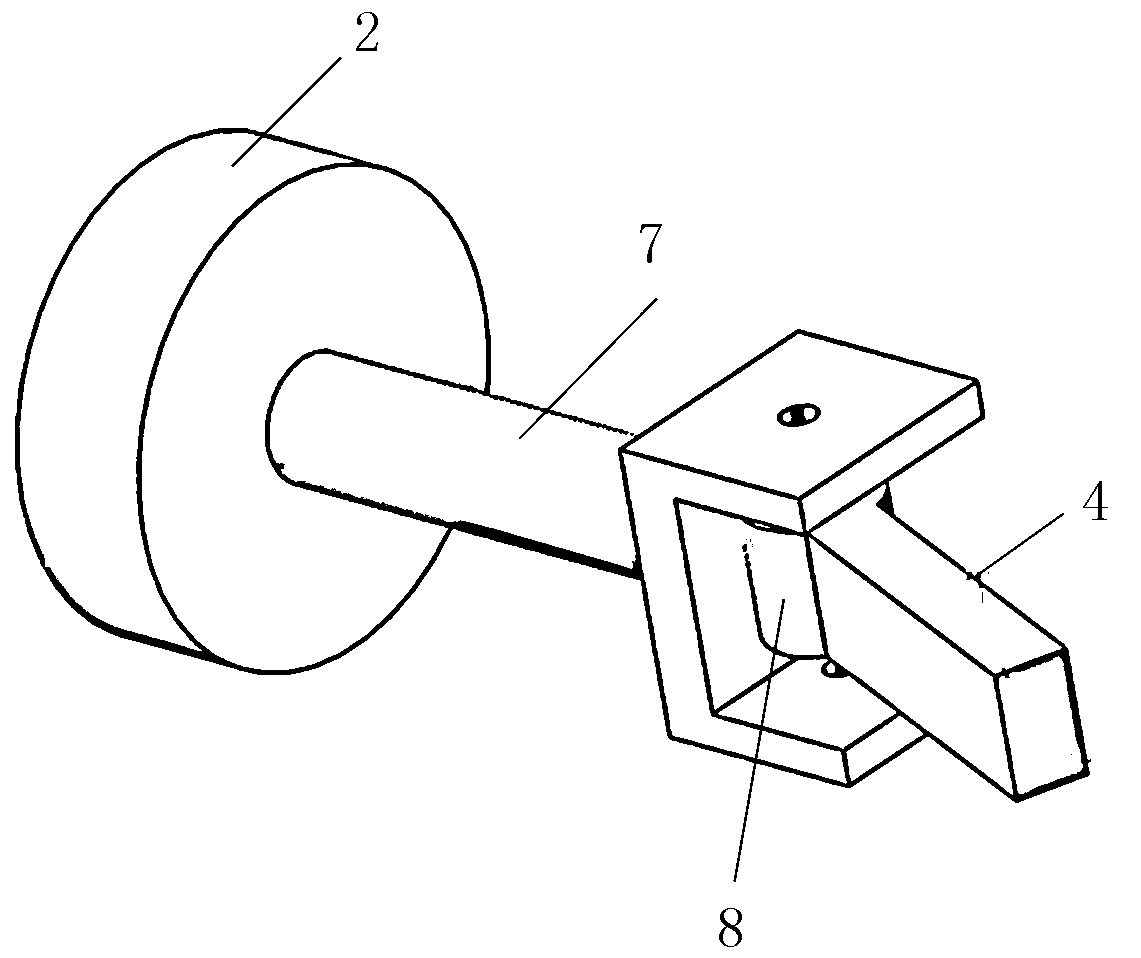

[0016] Such as figure 1 As shown, a vector propulsion mechanism of a modular underwater robot includes a propeller propulsion motor 6, a circular rotation module and a swing module, and the propeller propulsion motor 6, a circular rotation module and a swing module are arranged on the same axis; the circular rotation The module includes a circular rotation drive motor 2 and a circular rotation part of the protective shell 3. The swing module includes a swing drive motor 4 and a swing part of the protective shell 5. The circular rotation drive motor rotates circularly in the horizontal direction, and the output shaft 7 of the circular rotation drive motor It is connected with the casing of the swing driving motor to realize the rotation of the swing module; the other end of the casing is connected with the propeller propulsion motor 6, the motor shaft 8 of the swing driving motor is perpendicular to the output shaft 7 of the circular rotation driving motor, and the swing driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com