Dustproof device and method for rubber belt conveyor

A belt conveyor and dust-proof device technology, applied in conveyors, transportation and packaging, loading/unloading, etc., can solve the problems of easy generation of dust, inability to effectively control dust, and unfavorable health of staff, so as to achieve resource saving, Excellent effect and complete dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

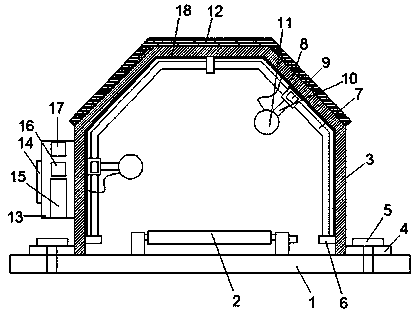

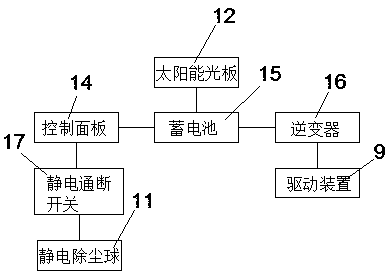

[0023] see Figure 1-2 : a kind of belt conveyor dustproof device, comprises machine tool 1, and machine tool 1 top center is provided with conveyor 2, and the outer upper part of conveyor 2 is provided with dustproof cover 3, and dustproof cover 3 left and right side wall bottoms and The top of the inner wall is provided with fixed rods 6, and guide rails 7 are arranged between the fixed rods 6 on the left and right sides and the fixed rods 6 on the top. The guide rails 7 on the left and right sides are respectively slidingly installed with moving carts 8, and the driving devices are installed on the movable carts 8. 9. The mobile trolley 8 is provided with a connecting rod 10, the head of the connecting rod 10 is provided with an electrostatic precipitator ball 11, the outer side wall of the dust cover 3 is provided with a control main box 13, and the side wall of the control main box 13 is installed There is a control panel 14, and the inside of the control main box 13 is r...

Embodiment 2

[0026] The embodiment of the present invention provides a dust-proof device for a belt conveyor. On the basis of Embodiment 1, the left and right ends of the bottom of the dust cover 3 are respectively provided with mounting plates 4, and the mounting plates 4 are fastened to the machine tool 1 by bolts 5. superior.

Embodiment 3

[0028] The embodiment of the present invention provides a dust-proof device for a belt conveyor. On the basis of Embodiment 1, the electrostatic dust removal balls 11 on the left and right sides are arranged toward the conveyor 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com