Vacuum glass integral support article preparation device

A vacuum glass and preparation device technology, which is applied in the field of preparation of vacuum glass supports, can solve the problems affecting the vacuum glass pumping and fusion process, the high time and cost of supports, the slippage and dislocation of glass and supports, etc., to achieve Reduce time and cost, optimize deployment, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] Referring to the accompanying drawings, the specific implementation is as follows:

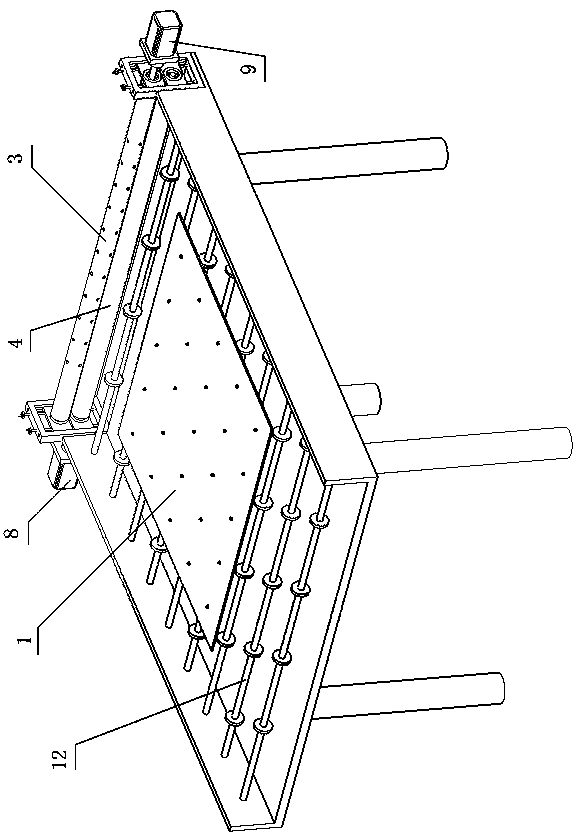

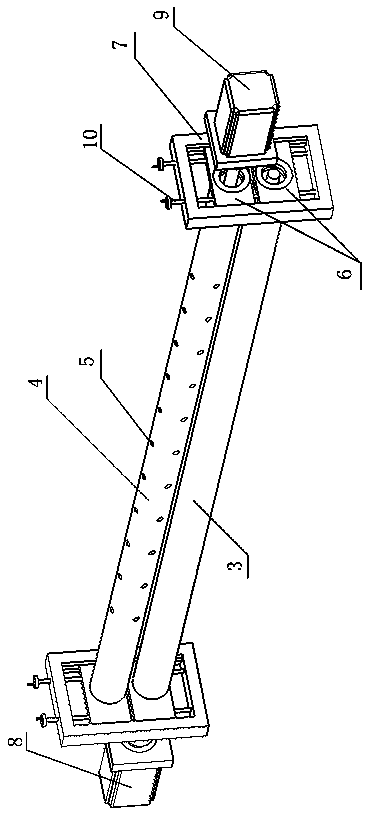

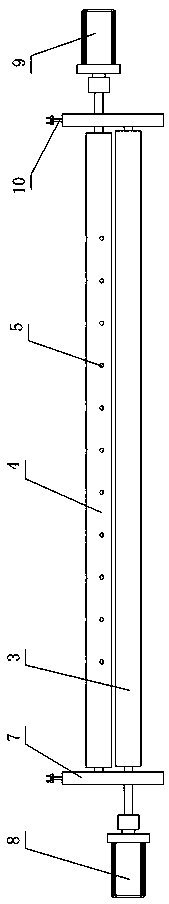

[0031] A vacuum glass integrated support preparation device, used to prepare and form a plurality of supports 2 for supporting another glass plate on one side of a glass plate 1, including two supports for rolling the glass plate 1 The roller shaft and the transmission mechanism for horizontally sending the glass plate 1 between the two roller shafts, the transmission mechanism includes a plurality of transmission rollers 12 for cooperating with the transfer glass plate 1, and the two roller shafts are arranged horizontally and along the Aligned vertically, the diameters of the cylindrical roller surfaces of the two rollers are the same, and the two rollers are driven by their respective motors to rotate synchronously and in reverse. A stepping motor 8 is provided on one side of the lower roller 3, and the upper roller The other side of the shaft 4 is provided with a servo motor 9; wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com