Four-channel hollow ingot fancy yarn forming device and method

A technology of fancy yarn and forming device, applied in the direction of yarn, spinning machine, continuous winding spinning machine, etc., can solve the problems of high production cost, lack of control means, low efficiency, etc., and reduce end breakage rate or singularity rate, stable drafting and twisting process, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

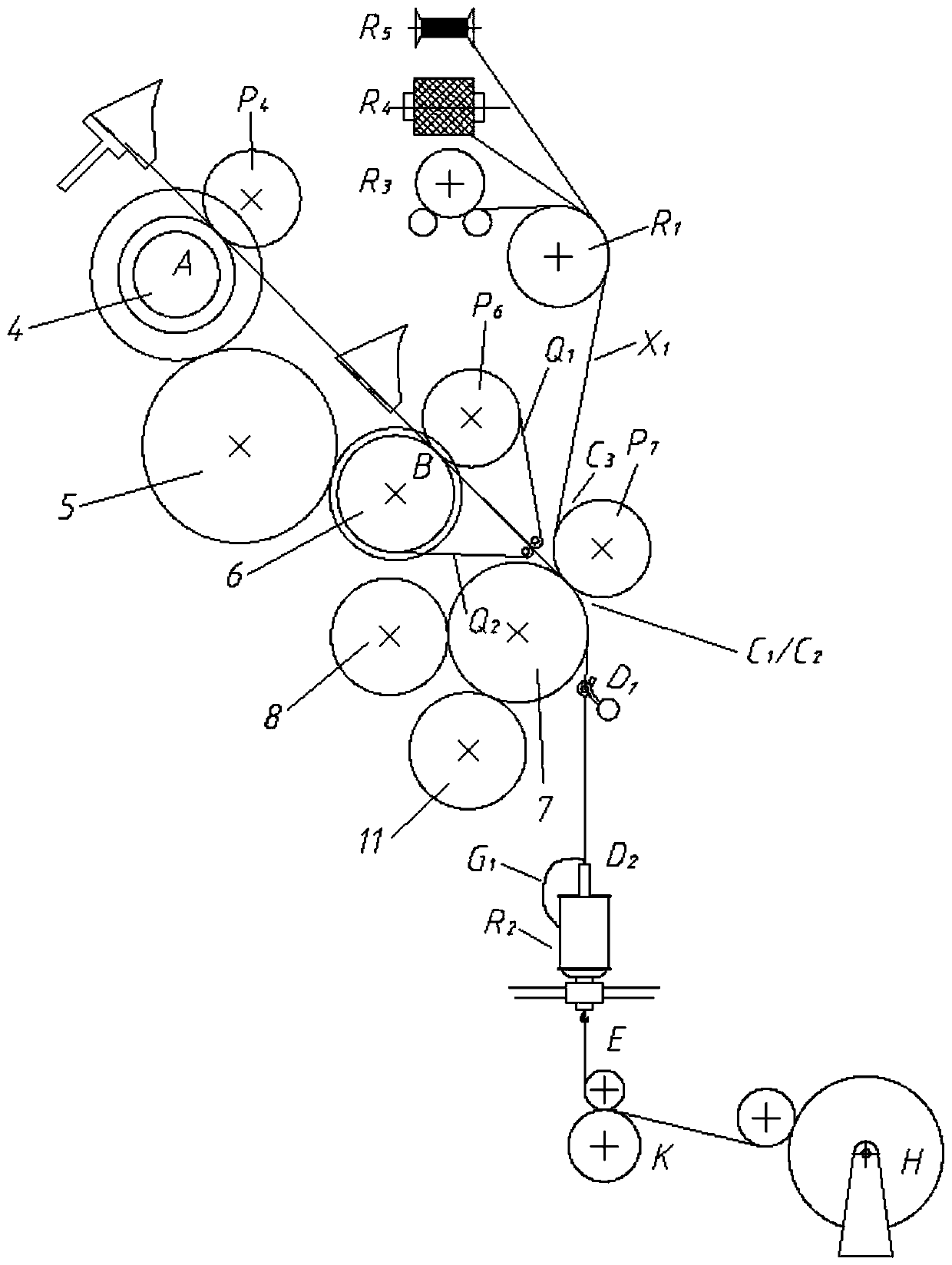

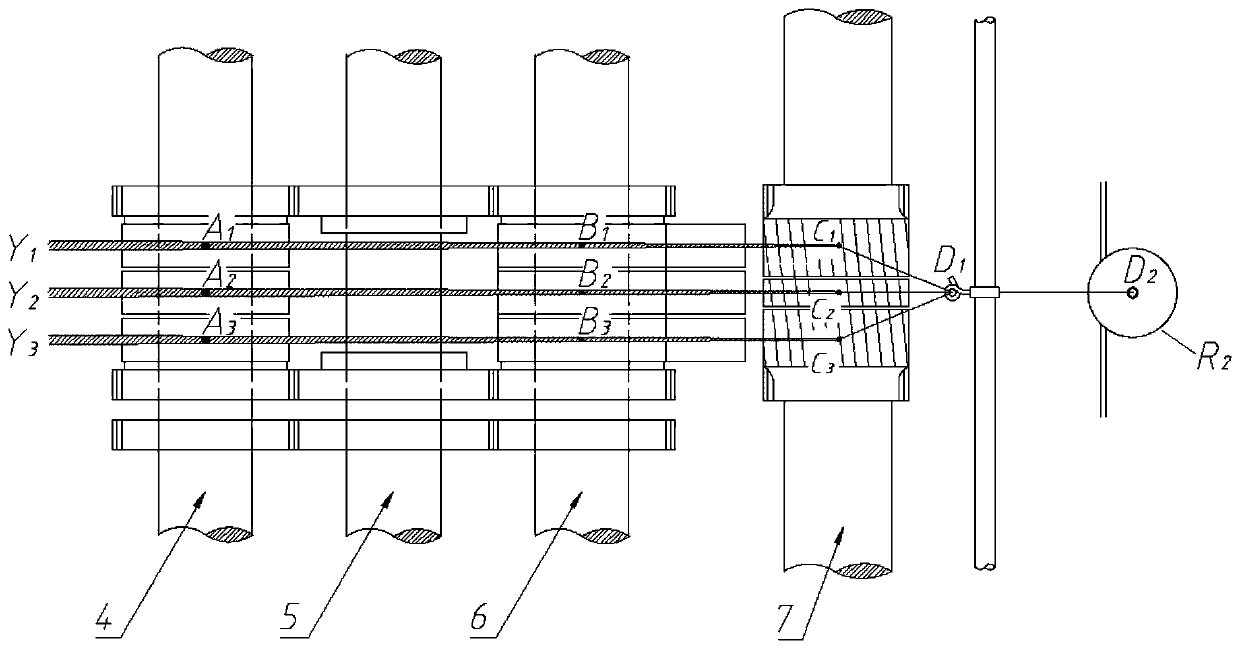

[0117] Such as Figure 1-3 As shown, a kind of four-channel hollow spindle fancy yarn forming device provided by the present embodiment includes: for the first component yarn Y 1 First channel A through 1 B 1 C 1 D. 1 D. 2 E. For the second component yarn Y 2 Second channel A through 2 B 2 C 2 D. 1 D. 2 E. For the third component yarn Y 3 Passed third channel A 3 B 3 C 3 D. 1 D. 2 E. For the fourth component yarn X 1 The fourth channel through R 1 C 2 D. 1 D. 2 e.

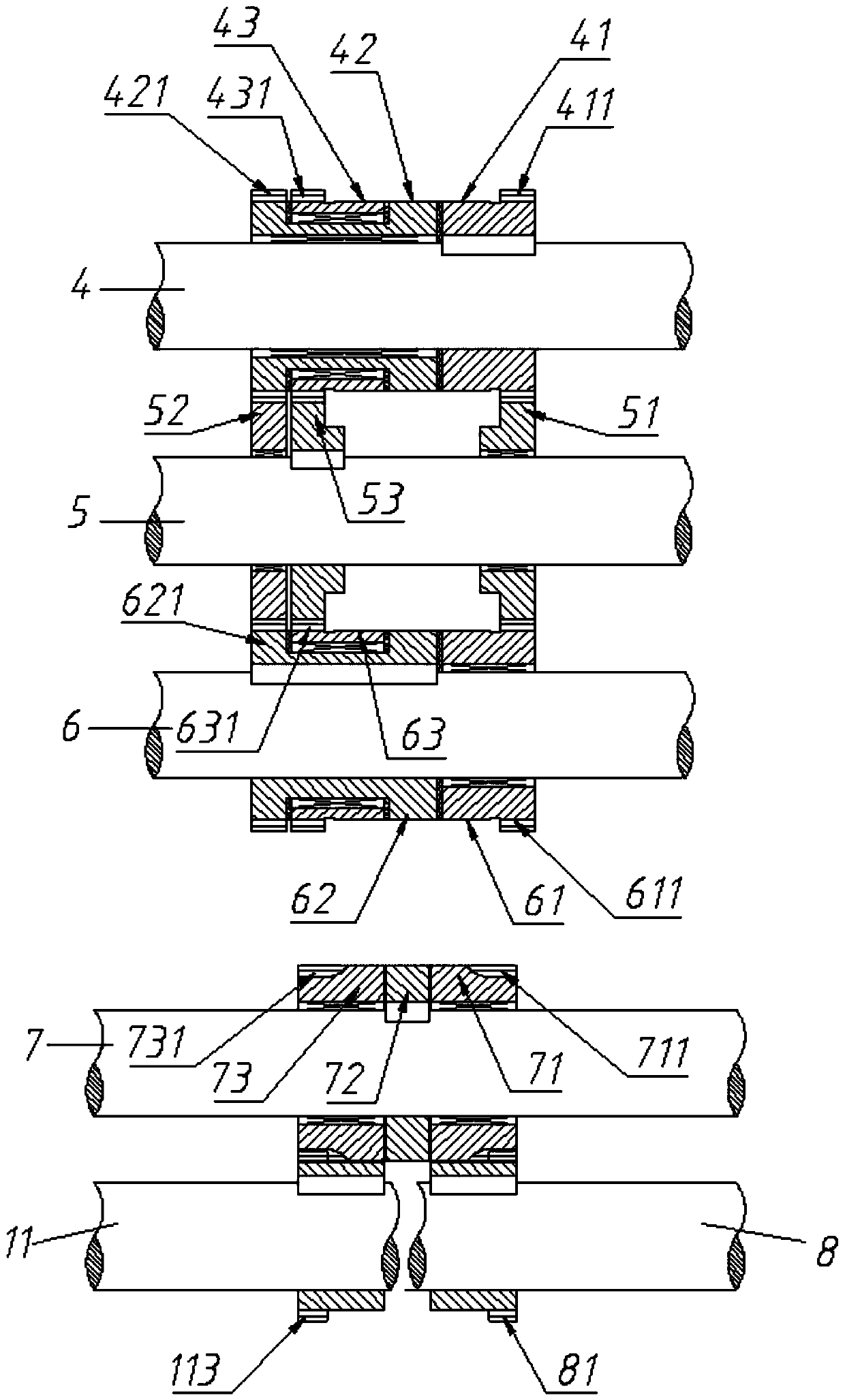

[0118] The first channel is sequentially provided with the first rear roller 41, the first middle roller 61, the first front roller 71, and the first twisting point D 1 and the second twist point D 2 ; The second passage is provided with the second back roller 42, the second middle roller 62, the second front roller 72, the first twisting point D in sequence 1 and the second twist point D 2 ; The third passage is provided with the third rear roller 43, the third middle roller 63, the third ...

Embodiment 2

[0139] In addition, this embodiment also discloses a fancy yarn forming method using the above-mentioned four-channel hollow spindle fancy yarn forming device.

[0140] 1. Spinning of decorative thread, core thread, and solid thread twisted into hollow spindle fancy yarn in one step

[0141] In the twisting triangle area of the first twisting point, three coaxial front rollers with the same outer diameter and different rotating speeds respectively output three paths of untwisted yarn and one path of spun yarn (or filament). combined to form the main body of the fancy yarn; at the second twisting point, the spun yarn (or filament) output from the fifth channel is covered and twisted with the main body of the formed fancy yarn to form a fancy yarn to realize decorative lines , core thread, fixed thread one-step hollow spindle fancy yarn spinning.

[0142] 2. Spinning of fancy yarn with winding structure changing online

[0143] By regulating the speeds of the rear rollers an...

Embodiment 3

[0201] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0202] Such as Figure 5 As shown, the control system also includes a first comparison module, the first comparison module is respectively connected with the first sensor, the second sensor, the third sensor and the controller, and the first comparison module is used to monitor the middle roller shaft 6 and the rear roller shaft 4 and the speed ratio between the auxiliary shafts, the controller regulates the speed of the middle roller shaft 6, the rear roller shaft 4 and / or the auxiliary shaft according to the numerical value fed back by the first comparison module, and then regulates the first component yarn, the second component yarn and the second component yarn The blending ratio of the three-component yarn.

[0203] In order to realize the adjustment of the yarn blending ratio accurately and quickly, the present invention directly adjusts and controls accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com