Rolling friction walkingjacking and pushing device for bridge segment installation

A technology of rolling friction and jacking devices, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problem of increasing the horizontal thrust at the top of bridge piers or temporary piers, which is prone to discrete jitter, and affects the smooth jacking construction of bridges and other problems, to achieve the effect of increasing the area, increasing the diameter of the cylinder body and improving the smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

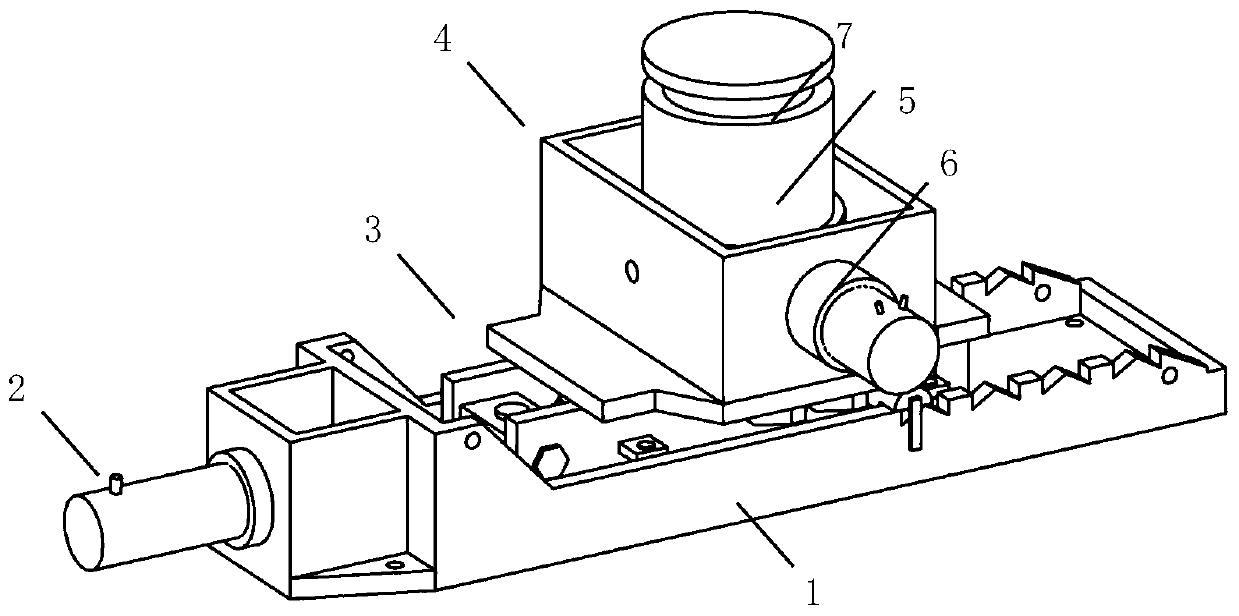

[0022] Such as figure 1 As shown, the trough-shaped walking track tray 1, the long-stroke jacking hydraulic jack 2, the mobile platform car 3, the steel plate box 4, the steel cup-shaped sliding shoe 5, the deviation-correcting hydraulic jack 6, and the center-lifting hydraulic jack 7 are assembled into a suitable Rolling friction type walking push-up device installed on the bridge section push-up.

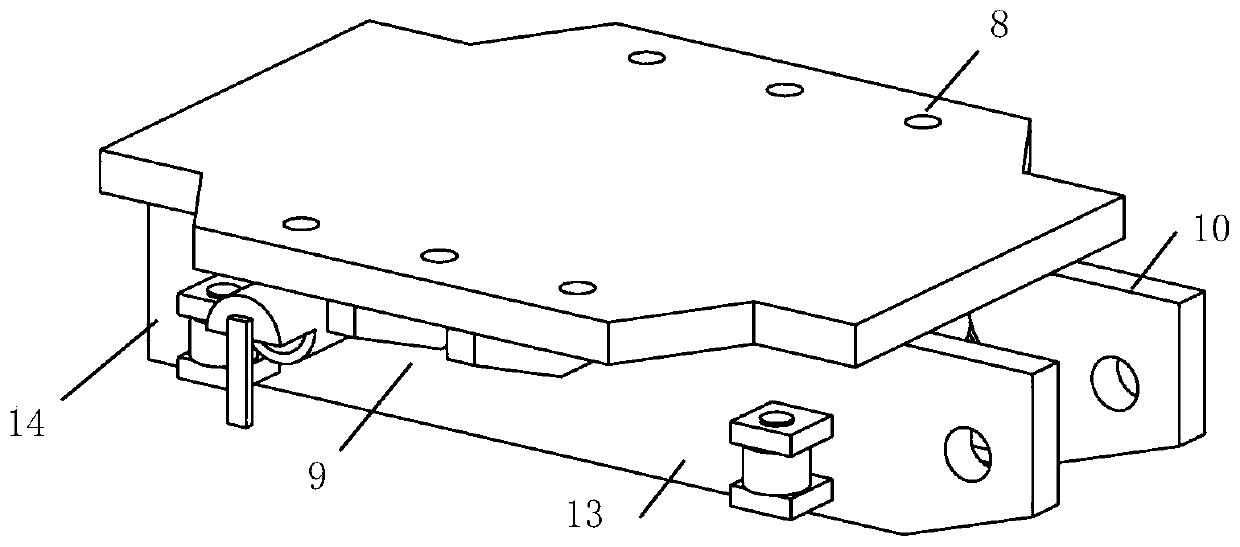

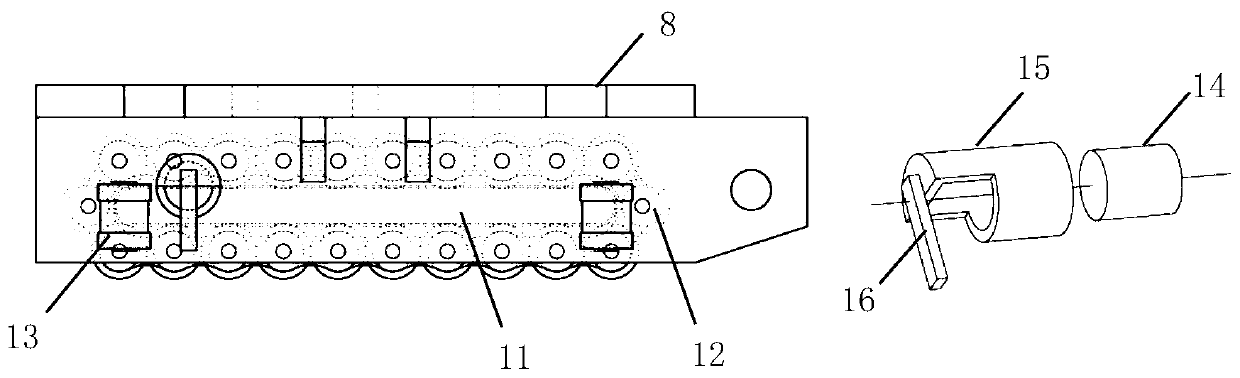

[0023] The realization of the function of longitudinal pushing and installation of the bridge girder body: the platform plate 8 of the mobile platform vehicle 3 is welded with two parallel vertical support plates 10 along the longitudinal pushing direction, and the outer side of the joint is welded with a triangular stiffener 9 for reinforcement. A pair of lateral limit rollers 13 are arranged on the outside of each vertical support plate 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com