a gear pump

A gear pump and gear cavity technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problem of inconvenient addition of lubricating fluid, and achieve the effect of compact structure, stable output flow, and guaranteed reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

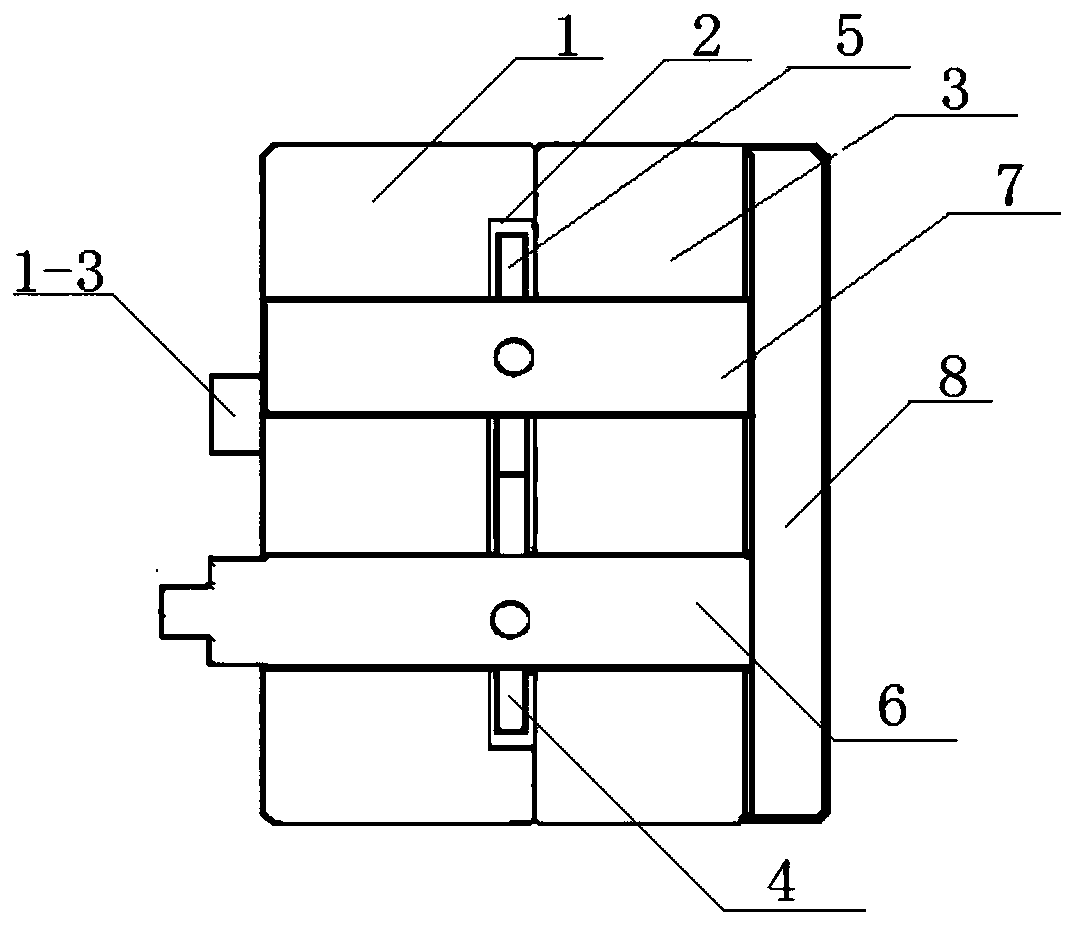

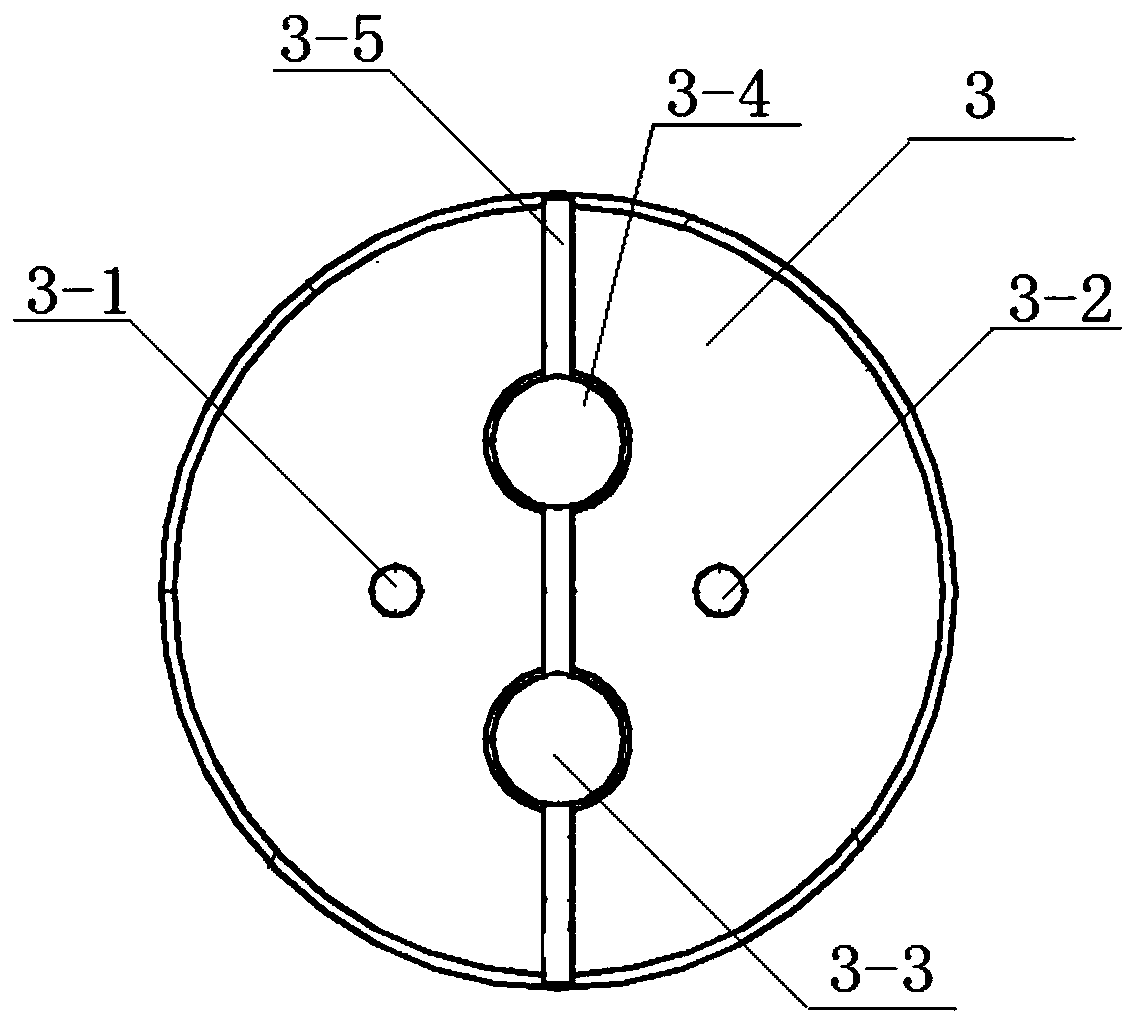

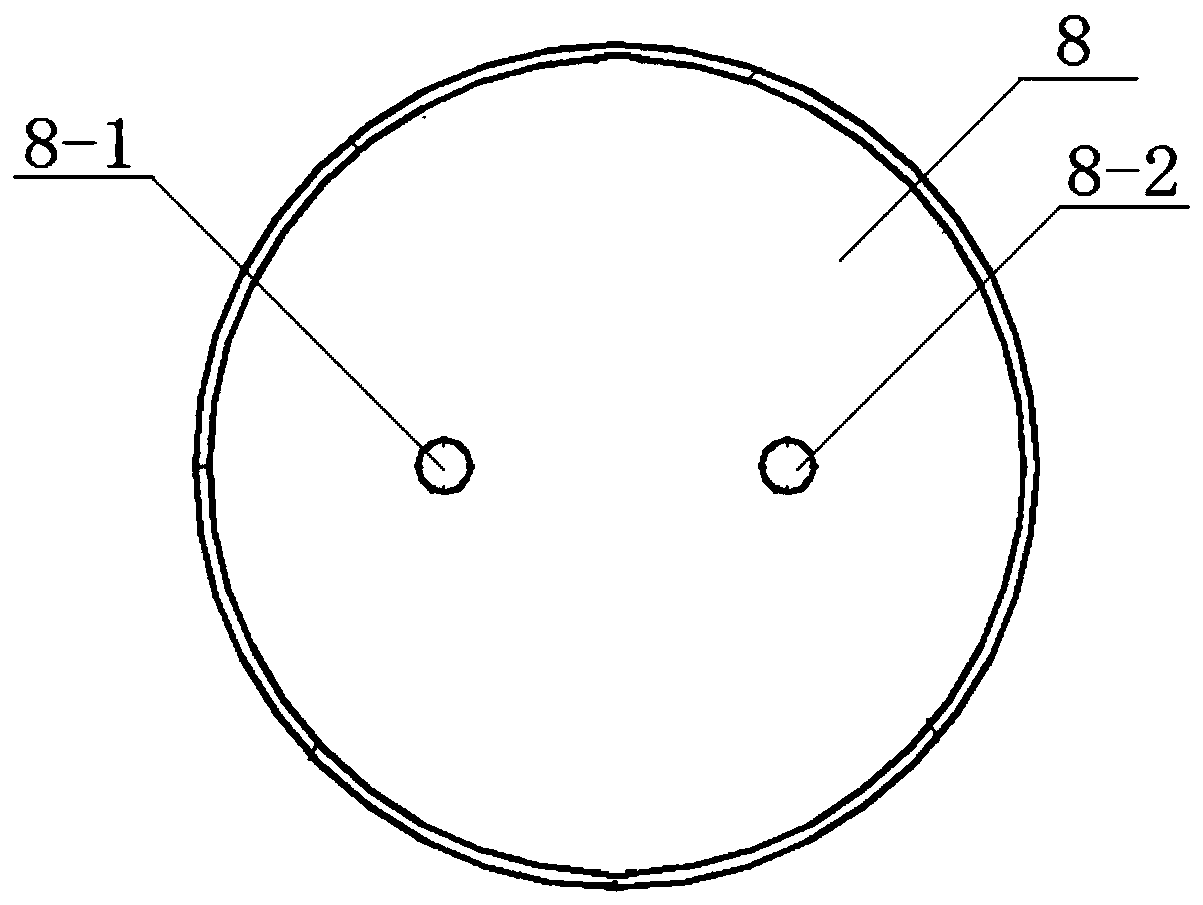

[0026] According to the above technical solution, this embodiment discloses a gear pump, which includes an upper pump cover 1, a hollow gear cavity 2 and a lower pump cover 3, and a driving gear 4 meshing with each other is arranged inside the hollow gear cavity 2. The driven gear 5, the driving gear 4 is sleeved on the driving shaft 6, the driven gear is sleeved on the driven shaft 7, and the lower pump cover 3 is also provided with an oil inlet 3 -1 and the oil outlet 3-2, the oil inlet 3-1 and the oil outlet 3-2 are respectively located on both sides of the straight line formed by the centers of the driving shaft 6 and the driven shaft 7.

[0027] Such as Figure 1-4 As shown, the overall structure of the gear pump disclosed in this embodiment is similar to the structure of the gear pump in the prior art, including an upper pump cover 1, a hollow gear cavity 2 and a lower pump cover 3 connected in sequence, wherein the upper pump cover 1 and the shape of the lower pump cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com