Opening and closing pipeline system for pipe well

A pipeline system and pipeline technology, applied in electrical components and other directions, can solve the problems of inconvenient cable entry and maintenance, difficult construction, inconvenient installation and maintenance of pipe gallery, etc., so as to improve the convenience and practicability of construction and convenient installation. The effect of quick and easy cable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

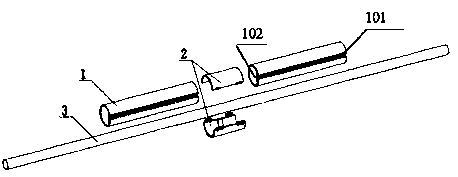

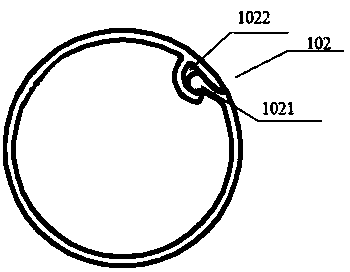

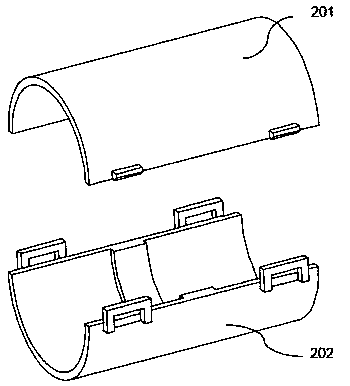

[0028] An open and close piping system for a pipe gallery, such as Figure 1~Figure 3 As shown, the pipeline system includes an openable pipeline 1 and a pipeline connection fitting 2. The pipeline connection fitting is used to connect two sections of the openable pipeline, wherein the side of the openable pipeline 1 has a slit 101, and the Both ends are provided with an openable structure 102, the openable structure 102 includes a first socket 1021 arranged at the lower opening of the end surface and a first socket 1022 arranged at the corresponding upper part of the end surface, the first socket 1021 is also spherical, The diameter of the first socket 1021 is greater than or equal to the wall thickness of the openable and closable pipeline. The pipeline connection fitting 2 includes a lower cover 201 and an upper cover 202 , and the lower cover 201 and the upper cover 202 are snap-fitted.

Embodiment 2

[0030] An open and close piping system for a pipe gallery, such as figure 1 , figure 2 and Figure 4 As shown, the pipeline system includes an openable pipeline 1 and a pipeline connection fitting 2. The pipeline connection fitting is used to connect two sections of the openable pipeline. The cover 201 and the upper cover 202, the four ends of the lower cover 201 are provided with a second socket 203, the second socket is spherical, the diameter of the ball is greater than or equal to the wall thickness of the lower cover 201, and the corresponding position of the upper cover 202 is provided with The second socket 204 corresponding to the socket 203, the second socket 204 is a Y-shaped accommodation cavity composed of the inner tube wall of the upper cover and the inner extended arc part;

[0031] There is a slit 101 on the side of the openable pipeline 1, and an openable structure 102 is arranged on both ends of the openable pipeline. The openable structure 102 includes a ...

Embodiment 3

[0036] An open and close piping system for a pipe gallery, such as figure 1 , figure 2 and Figure 6 As shown, the pipeline system includes an openable pipeline 1 and a pipeline connection fitting 2. The pipeline connection fitting is used to connect two sections of the openable pipeline. The cover 201 and the upper cover 202, and the four ends of the lower cover 201 are provided with second sockets 203, and the corresponding positions of the upper cover 202 are provided with a second socket 204 corresponding to the socket 203, and the second socket 204 is A Y-shaped accommodation chamber composed of the inner tube wall of the upper cover and the inner extended arc part, and a sealing strip 4 is provided at the joint between the socket and the socket;

[0037] There is a slit 101 on the side of the openable pipeline 1, and an openable structure 102 is arranged on both ends of the openable pipeline. The openable structure 102 includes a first socket 1021 arranged at the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com