Electric ice melting system and ice melting method thereof

An ice-melting method and ice-melting technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve problems such as power failure and ice melting of lines, and achieve the effect of improving ice resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

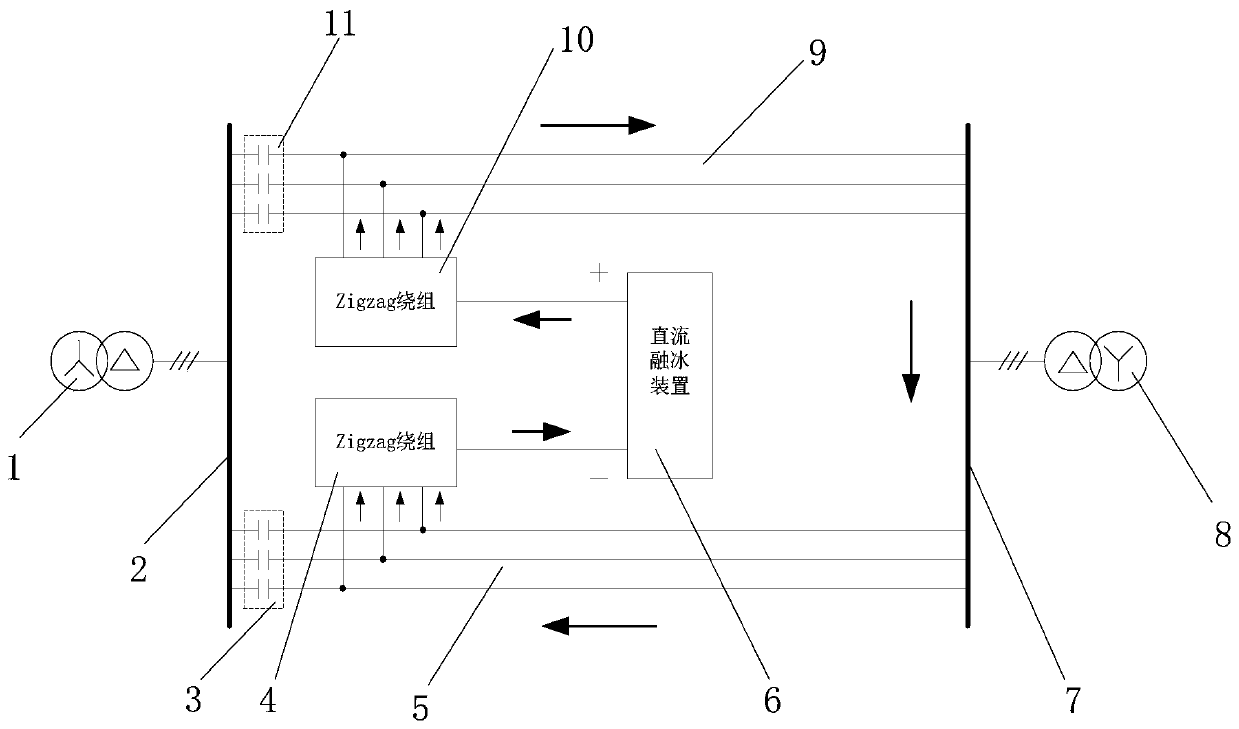

[0041] see figure 1 , which is a structural schematic diagram of an electrified ice-melting system provided in the embodiment of the present application.

[0042] Such as figure 1 As shown, the electrified ice melting system includes a first DC blocking device 3 , a second DC blocking device 11 , a first Zigzag winding 4 , a second Zigzag winding 10 and a DC ice melting device 6 . The first DC blocking device 3 and the second DC blocking device 11 are respectively connected in series on the return line between two main transformer busbars, and the two main transformers are the main transformer 1 of station A and the main transformer 2 of station B respectively. Among them, the main transformer 1 of station A is connected to the bus bar 2 of station A, the main transformer 1 of station B is connected to the bus bar 7 of station B, and the bus bar 2 of station A and the bus bar 7 of station B are connected in series through the first line 5 and the second line 9 to form return...

Embodiment 2

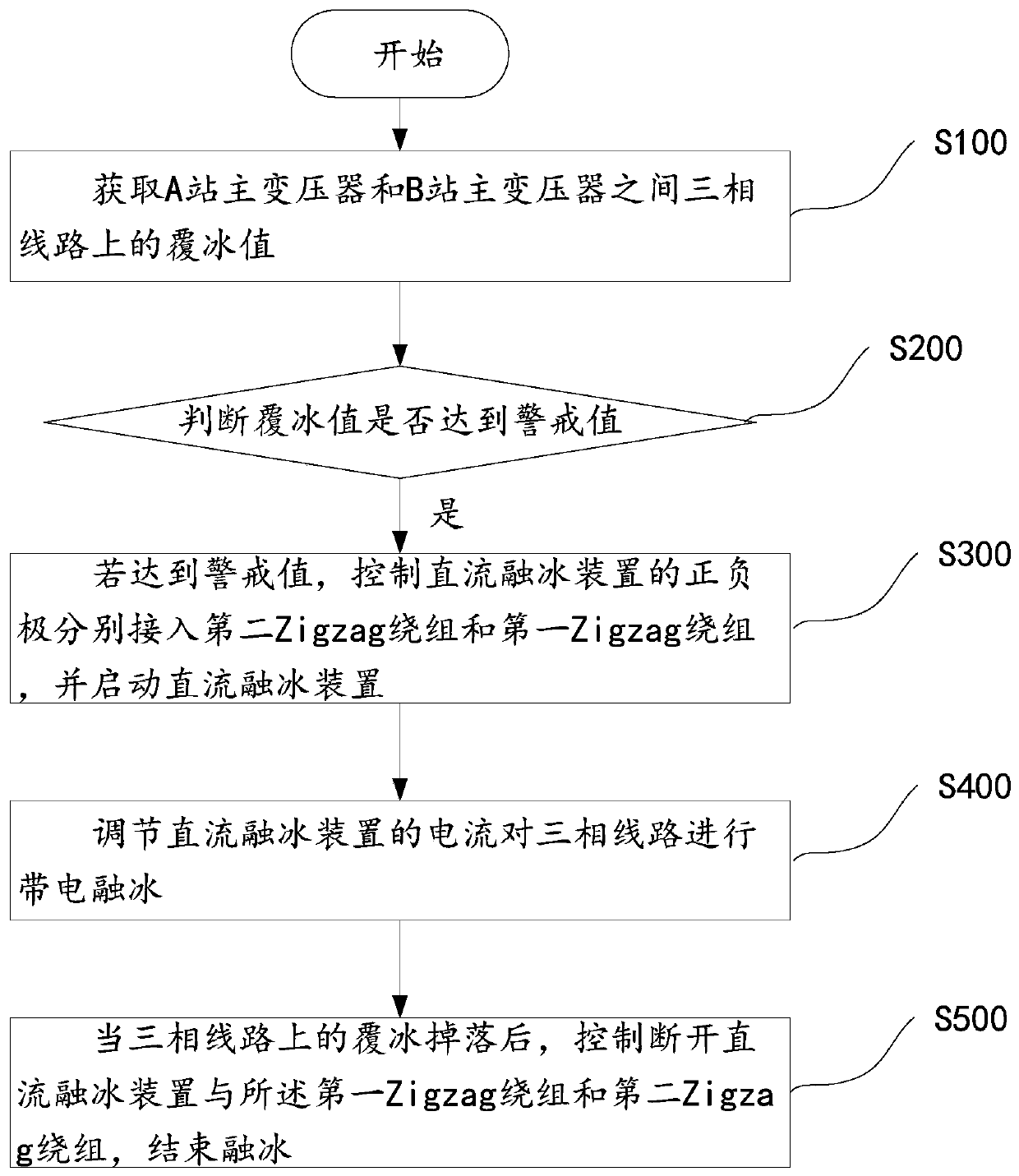

[0056] The embodiment of the present application also provides a charging ice-melting method, which is applied to the charging ice-melting system provided in the first embodiment. see image 3 , is a schematic flow chart of a charging ice-melting method provided in the embodiment of the present application.

[0057] In step S100, the icing value on the three-phase line between the main transformer of station A and the main transformer of station B is obtained.

[0058] During the specific implementation process, a surveillance camera can be installed on the three-phase line between the main transformer of station A and the main transformer of station B, or a real-time picture of the three-phase line can be taken by a drone. The pictures are compared to calculate the icing value. Specifically, how to calculate the above-mentioned method of the ice-covering value can refer to the calculation of the ice-covering value in the prior art, and will not be elaborated here.

[0059]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com