A high-power parallel inverter dual power supply dual furnace arbitrary switching device

A switching device and inverter technology, applied in building fastening devices, building locks, buildings, etc., can solve problems such as low power, easy opening of capacitor cabinets, hidden safety hazards, etc., to prevent unauthorized opening and improve anti-technical properties The effect of difficulty on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

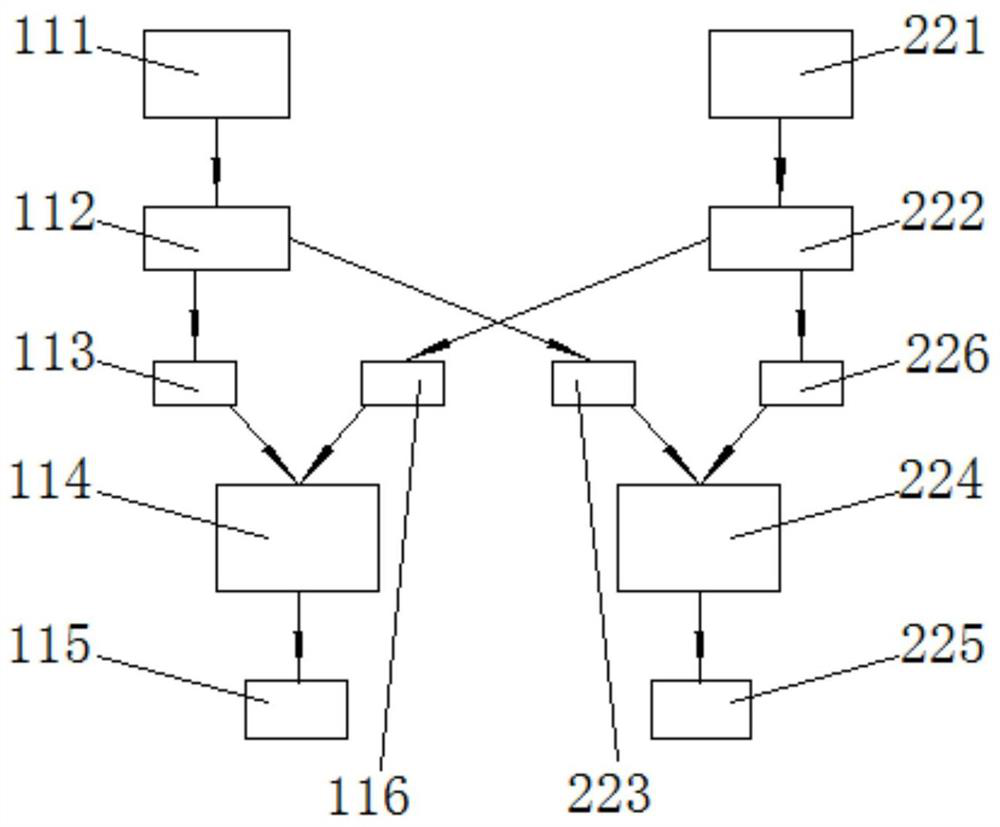

[0042] A high-power parallel inverter dual power supply double furnace arbitrary switching device, including a first transformer 111, a second transformer 221, a first power supply 112, a second power supply 222, a first capacitor cabinet 114, a second capacitor cabinet 224, The first induction furnace 115 and the second induction furnace 225, the first transformer 111 is electrically connected to the first power supply 112, the first capacitor cabinet 114 is provided with a first switch 113 and a second switch 116, the first One end of the first switch 113 and the second switch 116 are electrically connected to the first induction furnace 115, the other end of the first switch 113 is electrically connected to the first power supply 112, and the second transformer 221 is electrically connected to the second power supply 222. connection, the second capacitor cabinet 224 is provided with a third switch 223 and a fourth switch 226, one end of the third switch 223 and the fourth sw...

Embodiment 2

[0047] The same as embodiment 1 is no longer repeated, and the difference with embodiment 1 is:

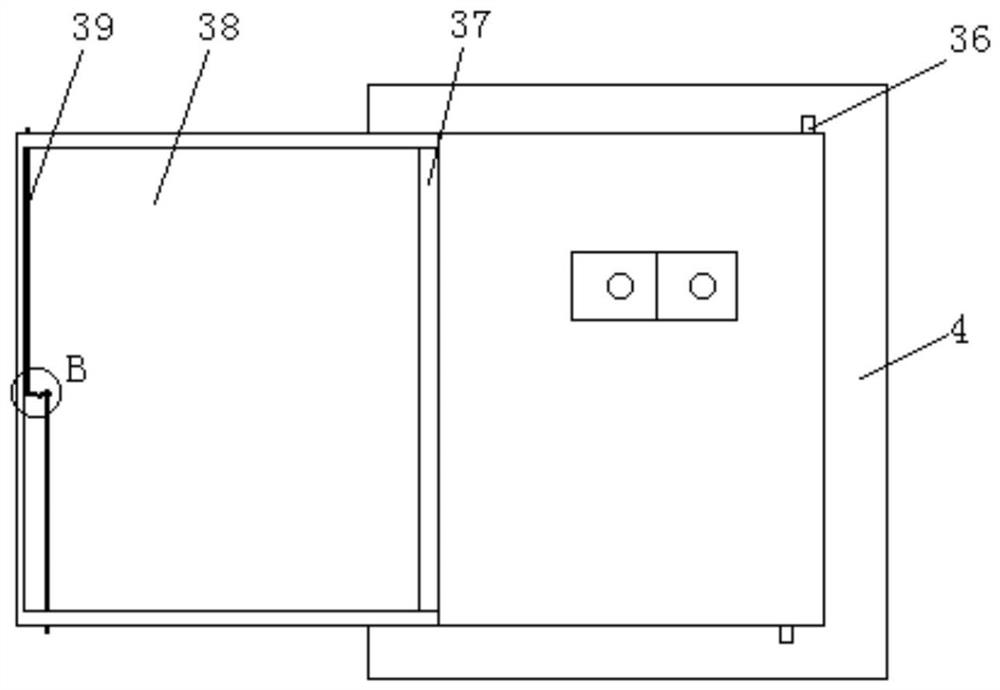

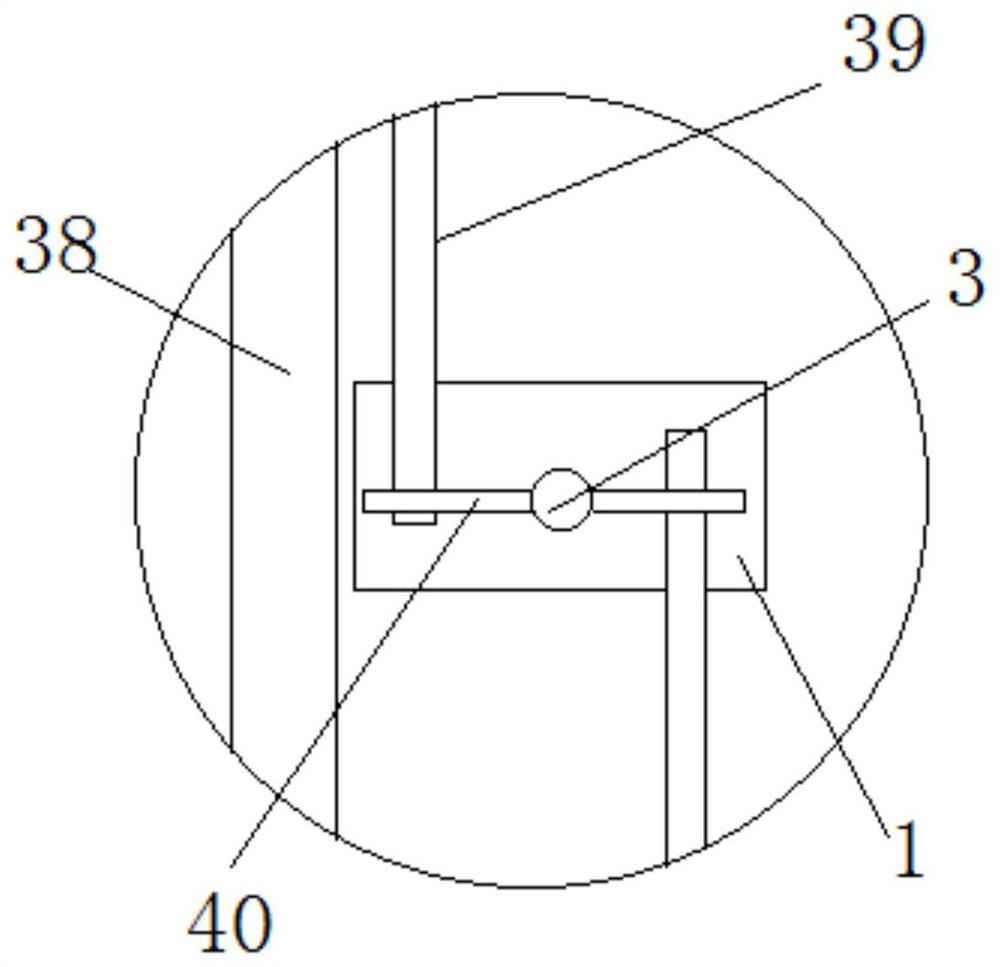

[0048] Described capacitor cabinet cabinet body 4 entrances are provided with cabinet door 38, and described cabinet door 38 one side is movably connected with capacitor cabinet cabinet body 4 by rotating shaft 37, and described cabinet door 38 is provided with the lock body 1 that is fixedly connected, so The lock body 1 is provided with a rotatable lock core 2, and the lock core 2 positioned at the inner side of the cabinet door 38 is provided with a fixedly connected lock bar 3, the lock bar 3 moves through the lock body 1, and the lock bar 3. A fixedly connected shaft 40 is provided on the outside, and the two ends of the shaft 40 are provided with clamping rods 39 distributed up and down. The inside of the capacitor cabinet body 4 is provided with a clamping groove 36 that engages with the clamping rods 39. A key 20 matching the lock cylinder 2 is provided on the lock cylinde...

Embodiment 3

[0056] The same as embodiment 2 will not be repeated, and the difference from embodiment 2 is:

[0057] The cross section of the lock core 2 is convex, and the lock core 2 at the bottom of the lock hole 8 is provided with a number of uniform second lower fixing grooves 14 that communicate with the lock hole 8, and inside the second lower fixing grooves 14 A matching second lower fixing rod 10 is provided, and a matching lock block 9 is provided at the bottom of the lock hole 8, and a connecting rod 32 is provided at the bottom of the locking block 9, and the two ends of the connecting rod 32 are provided with rotatable The connecting shaft 15, and the two ends of the connecting rod 32 are respectively connected with the lock block 9 and the second lower fixing rod 10 through the connecting shaft 15, and the inner wall of the lock body 1 is provided with a number of matching with the second lower fixing groove 14 The second upper fixing groove 16, the second upper fixing rod 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com