Method for rapidly assembling, disassembling and replacing cold plate component of multi-layer liquid cooling frame

A liquid-cooled rack and cold plate technology, applied in cooling/ventilation/heating transformation, etc., can solve the problems of cold plate coolant outflow, pollution of equipment, inconvenient maintenance work, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

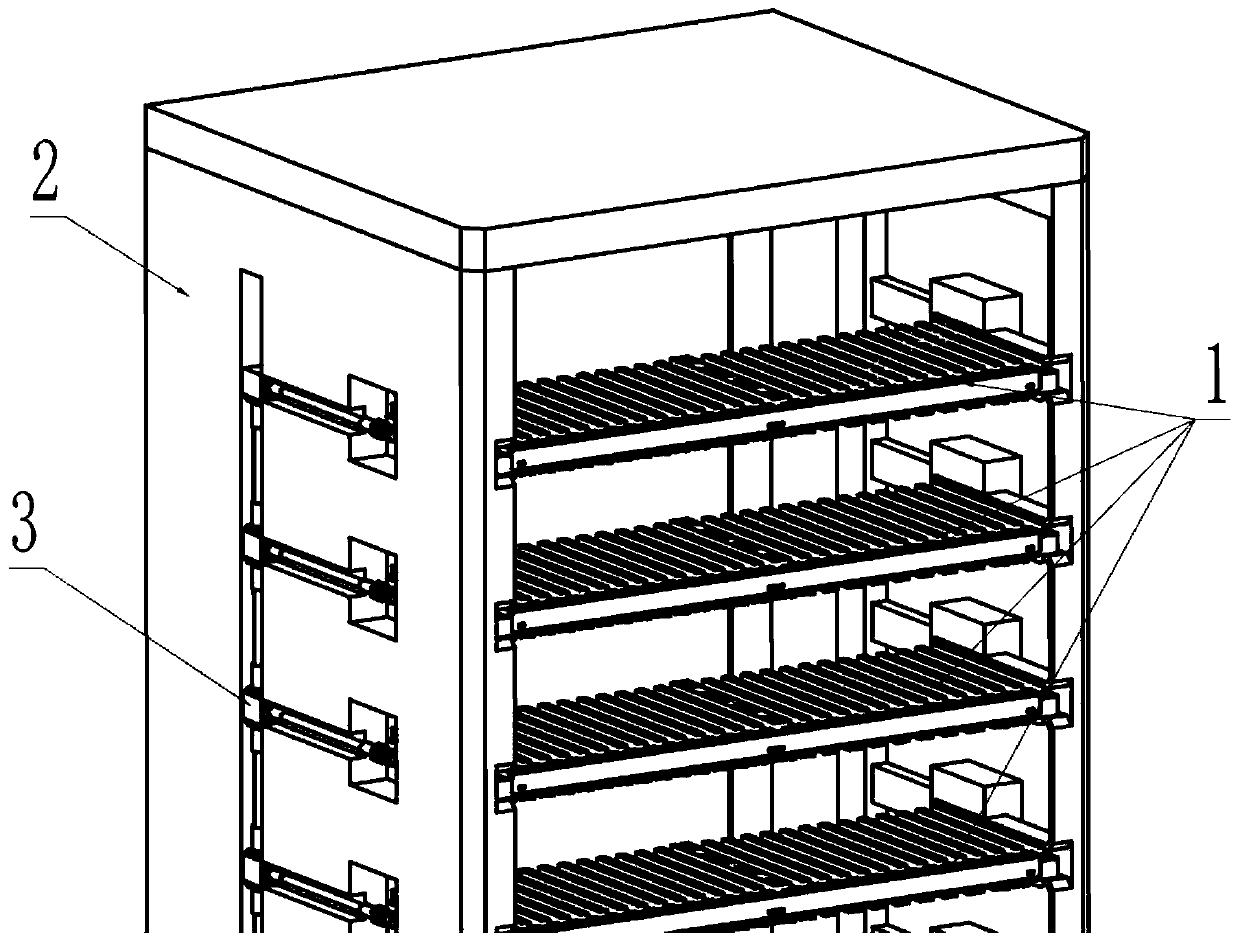

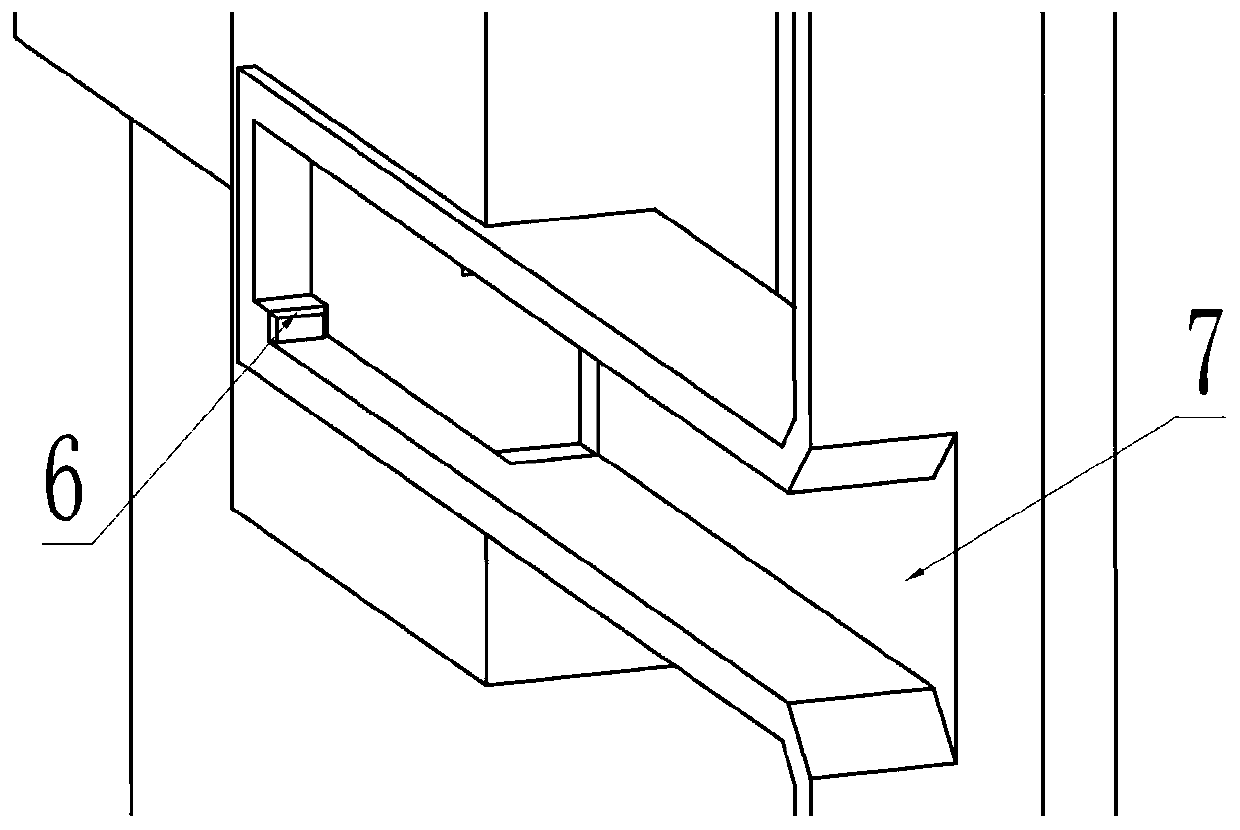

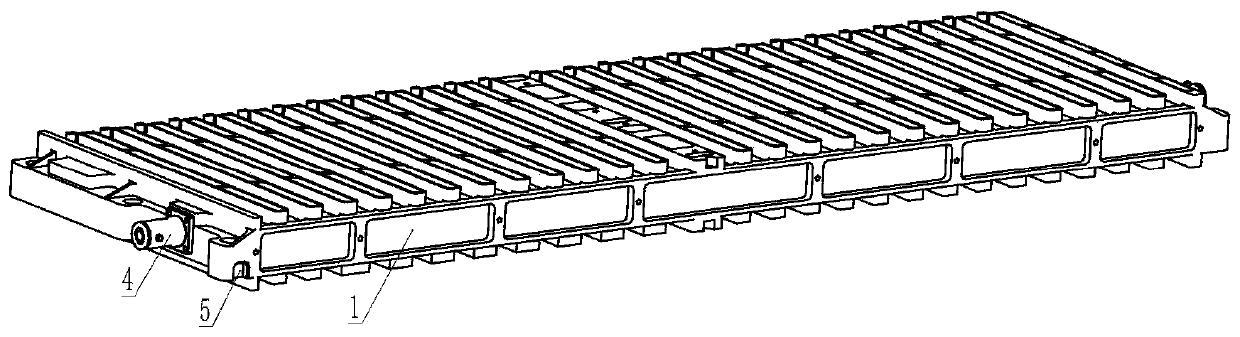

[0016] refer to Figure 1-Figure 3 . According to the present invention, the installation position of the cold plate assembly 1 assembled on the inner cavity shelf of the liquid cooling rack 2 is designed as a guide groove structure. The double U-shaped guide groove structure 7 realizes the insertion, pull-out guidance and support of the cold plate assembly 1; the matching position of the ends of the sliders on both sides where the cold plate assembly 1 is inserted to the bottom adopts the stopper at the end of the double U-shaped guide groove structure 7 Step 6 for positioning; the cold plate assembly 1 is inserted into the slide rail of the plug-in drawer with sufficient clearance through the inner guide grooves of the vertical plates on both sides of the liquid cooling rack 2, and a self-sealing fluid connector is installed at the liquid inlet and outlet of the cold plate assembly 1 4. The liquid flow in and out of the liquid-cooled rack end adopts a flexible liquid flow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com