Bottom dead center absolute value detection device and method

A detection device and absolute value technology, applied in presses, metal processing equipment, metal processing, etc., can solve the problems of low bottom dead center positioning accuracy, lack of compensation ability, and cumbersome adjustment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

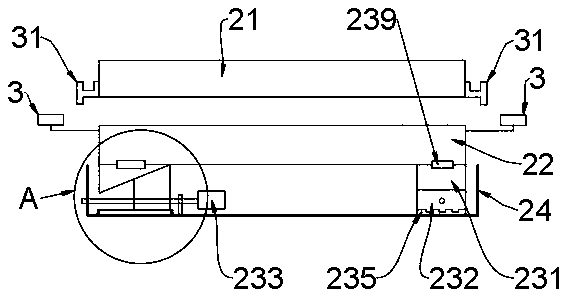

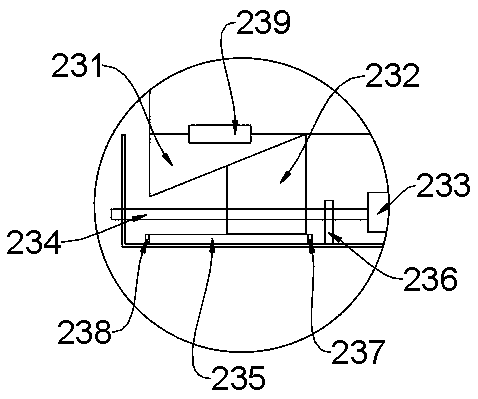

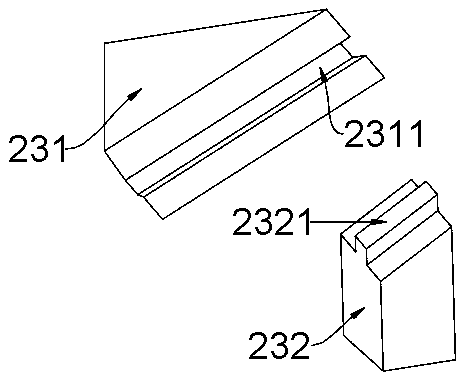

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] Bottom dead center absolute value detection device, including a detector, a fixing seat and four magnetic sensors 3;

[0033] Such as Figure 5 and Figure 6 The shown detector includes a PLC 11, a power module 12, a receiving module 13, a sensor module 14, a display 15, an information transmission module 16, a hard disk 17 and a filter 18, the power module 12 is electrically connected to the receiving module 13, the PLC 11, the sensor The module 14, the display 15 and the information transmission module 16 are respectively electrically connected to the receiving module 13, the sensor module 14, the information transmission module 16, the display 15 and the hard disk 17 are respectively electrically connected to the PLC 11, and the magnetic sensor 3 is electrically connected to the sensor module 14. Connect; the information transmission module 16 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com