Self-sealing integrated wet spraying machine material distributing device and preparation method thereof

A material distributing device and integrated technology are applied in the field of self-sealing integrated wet spraying machine distributing device and its preparation field, which can solve the problems of high labor intensity and cost, high repair cost, difficult replacement operation, etc., and achieve cost reduction. and labor intensity, improve the stability of equipment operation, and the effect of processing workpieces is simple and easy to grasp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

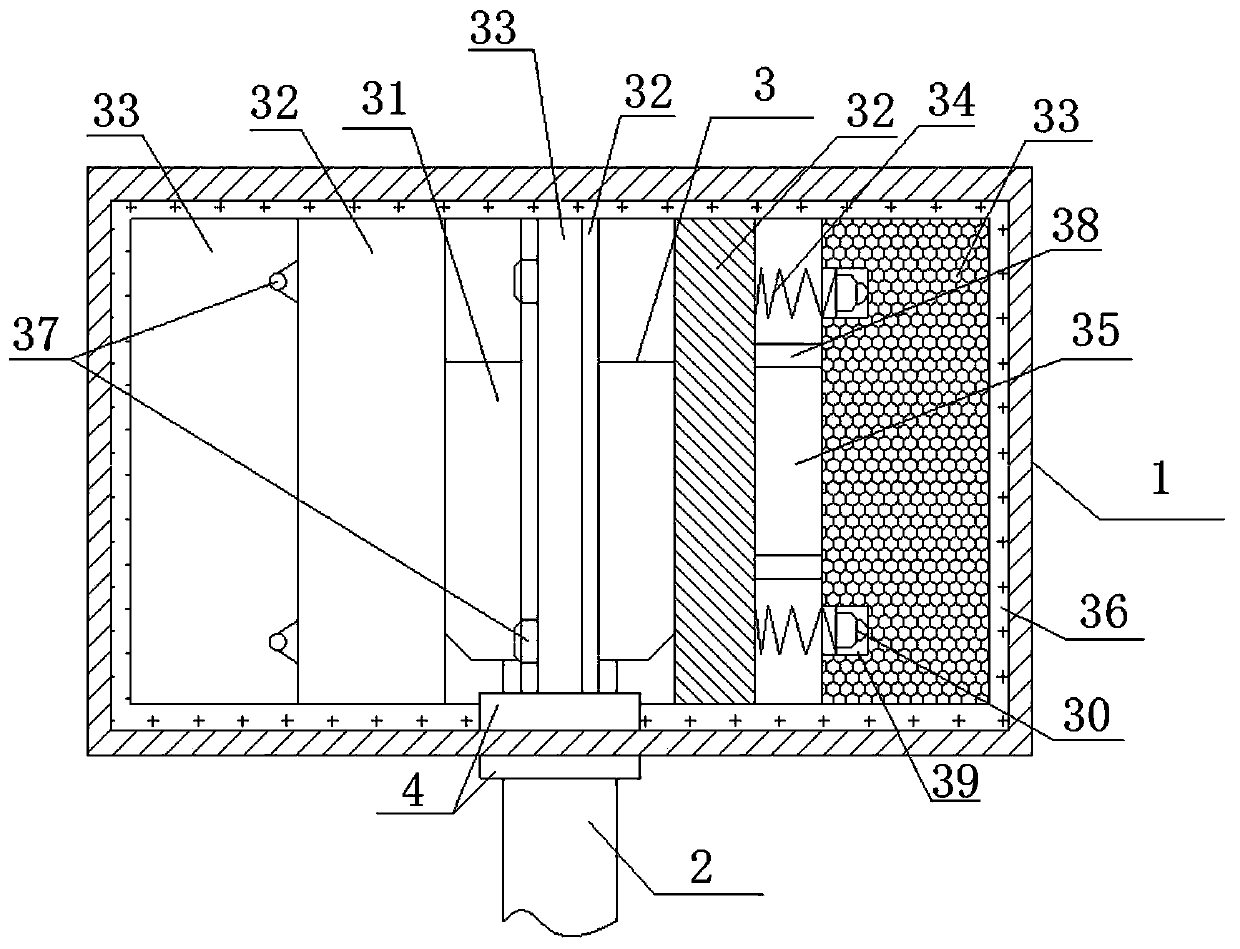

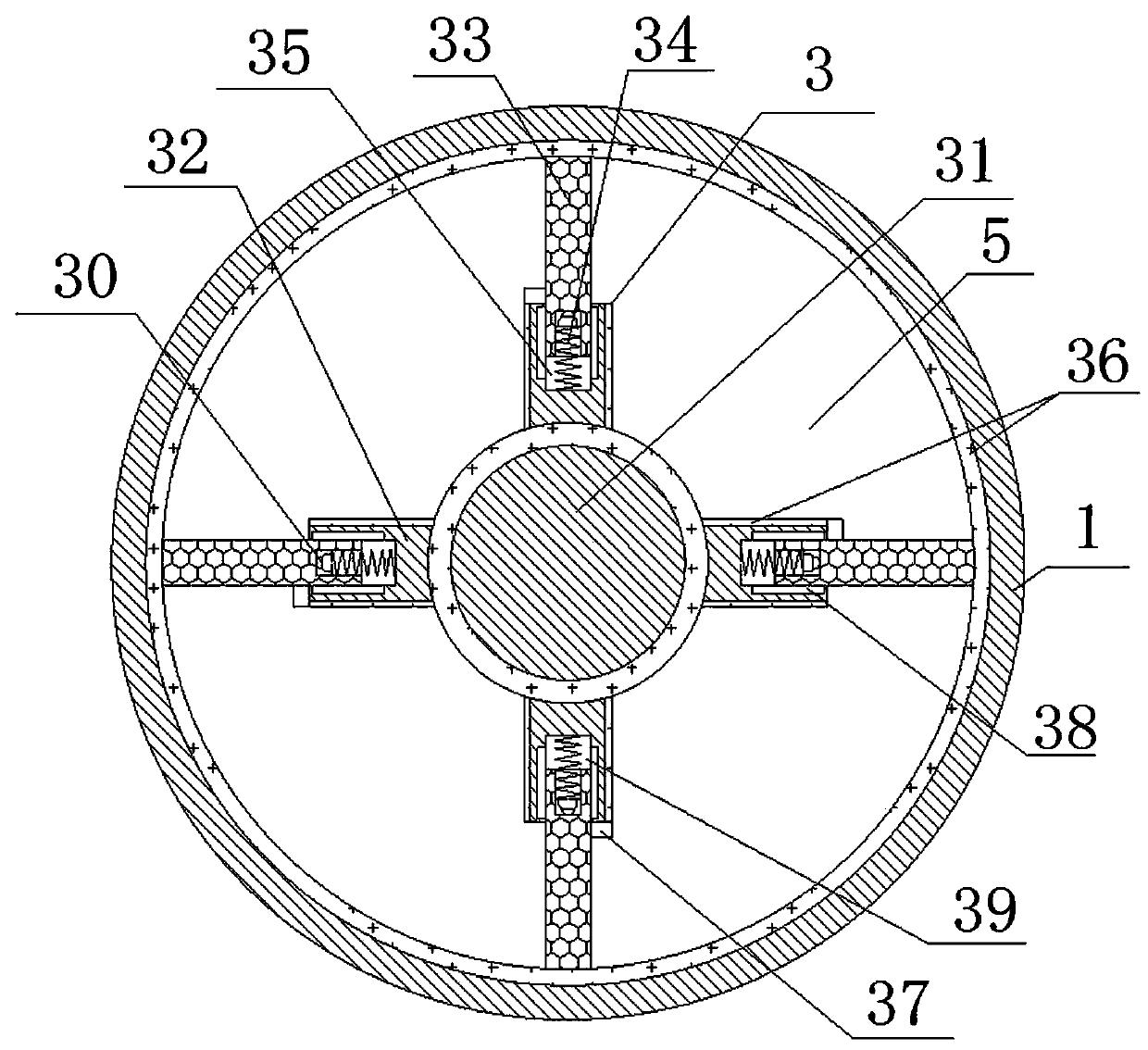

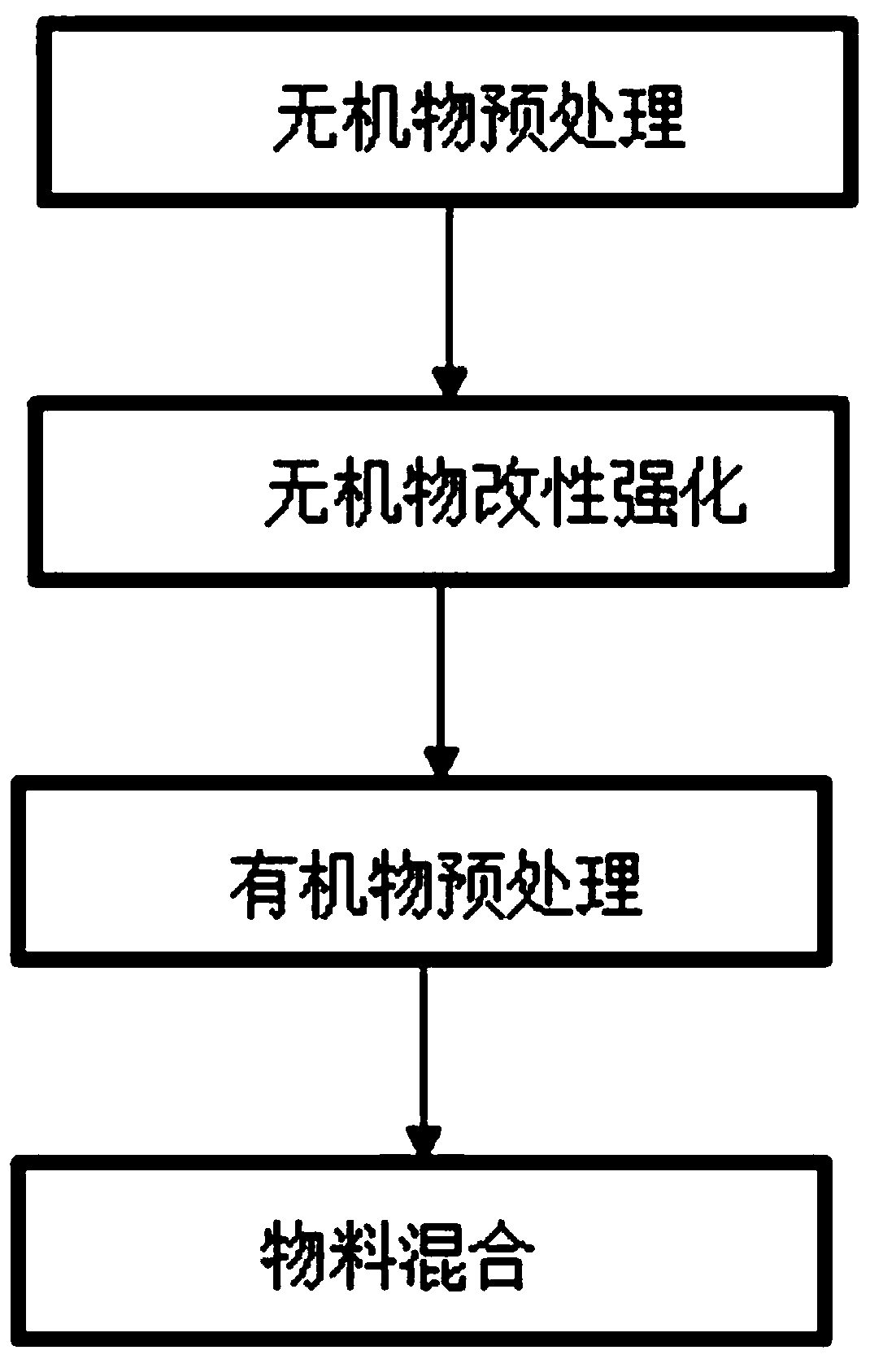

[0031] Such as figure 1 As shown, a preparation process of a self-sealing integrated wet spraying machine distribution device includes the following steps:

[0032] S1, to prepare the blank, first cast the base column and the metal load-bearing baffle of the material cylinder and the distribution wheel according to the parts drawings and process requirements, and carry out an integral integration of the base column and the metal load-bearing baffle Casting processing, the drive shaft and hard polymer baffle are processed by machine tools, and then the cast barrel, the base column of the distribution wheel and the metal bearing baffle, the drive shaft and the surface of the hard polymer baffle are passed through The machine tool performs secondary processing to make the surface precision of the base column of the distribution wheel and the metal bearing baffle meet the process requirements, and prepare the barrel, the base column of the material distribution wheel, the metal be...

Embodiment 2

[0040] Such as figure 1 As shown, a preparation process of a self-sealing integrated wet spraying machine distribution device includes the following steps:

[0041] S1, to prepare the blank, first cast the base column and the metal load-bearing baffle of the material cylinder and the distribution wheel according to the parts drawings and process requirements, and carry out an integral integration of the base column and the metal load-bearing baffle Casting processing, the drive shaft and hard polymer baffle are processed by machine tools, and then the cast barrel, the base column of the distribution wheel and the metal bearing baffle, the drive shaft and the surface of the hard polymer baffle are passed through The machine tool performs secondary processing to make the surface precision of the base column of the distribution wheel and the metal bearing baffle meet the process requirements, and prepare the barrel, the base column of the material distribution wheel, the metal be...

Embodiment 3

[0049] Such as figure 1 As shown, a preparation process of a self-sealing integrated wet spraying machine distribution device includes the following steps:

[0050] S1, to prepare the blank, first cast the base column and the metal load-bearing baffle of the material cylinder and the distribution wheel according to the parts drawings and process requirements, and carry out an integral integration of the base column and the metal load-bearing baffle Casting processing, the drive shaft and hard polymer baffle are processed by machine tools, and then the cast barrel, the base column of the distribution wheel and the metal bearing baffle, the drive shaft and the surface of the hard polymer baffle are passed through The machine tool performs secondary processing to make the surface precision of the base column of the distribution wheel and the metal bearing baffle meet the process requirements, and prepare the barrel, the base column of the material distribution wheel, the metal be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com