Lifting device and method for hooking or unhooking hanger shaft

A lifting device and hook technology are applied in the directions of load hanging components, transportation and packaging, which can solve the problems of laborious manual operation, high price and low reliability, and achieve simple structure, high operability and reliability, and high cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

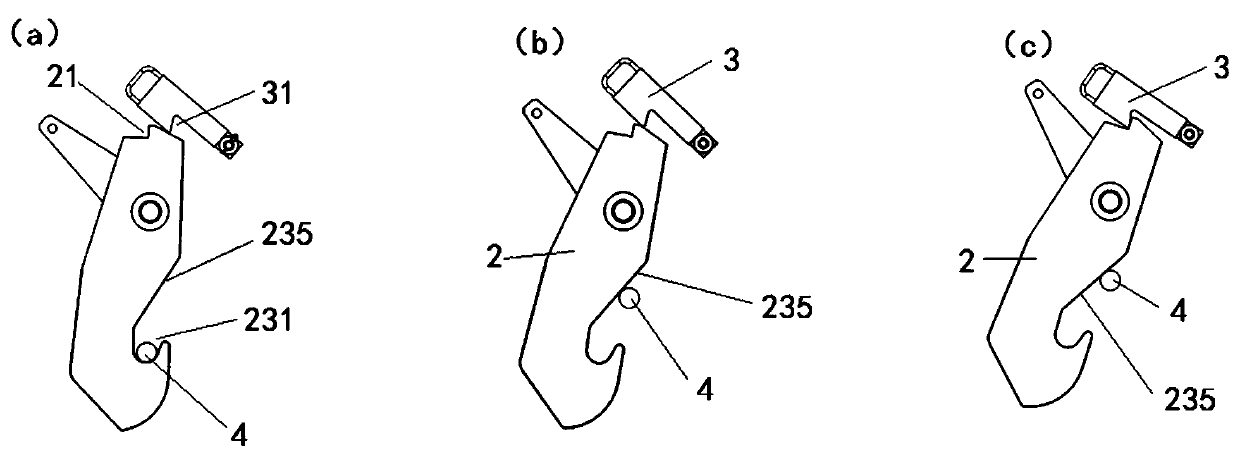

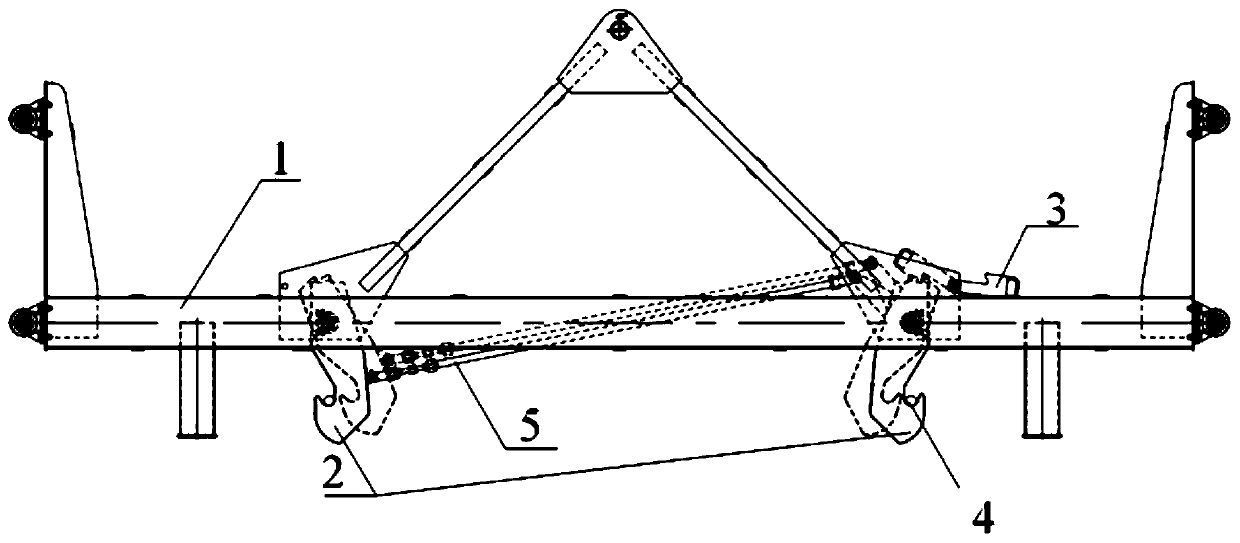

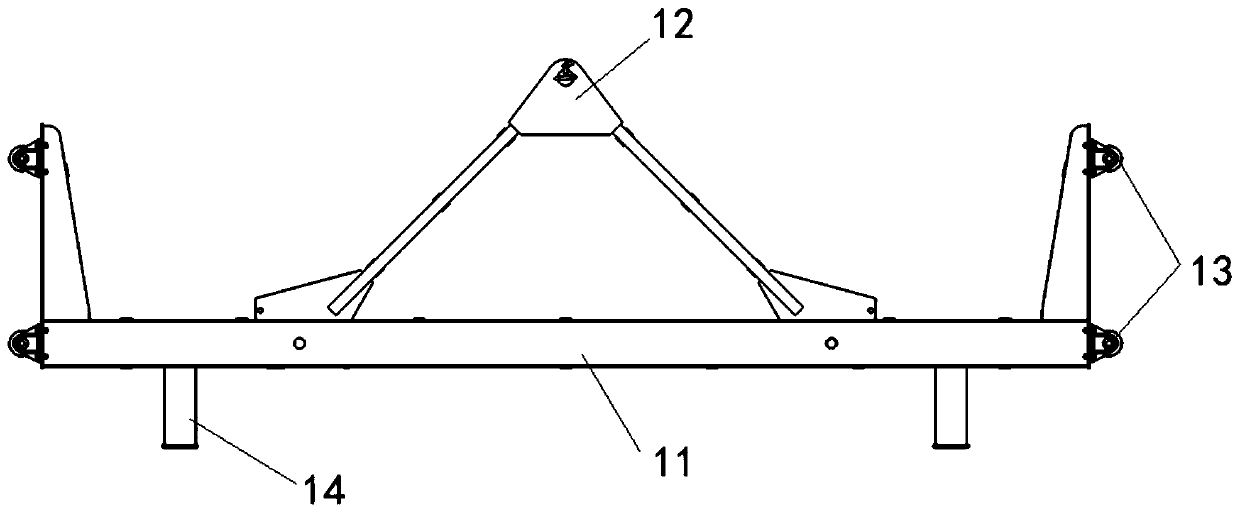

[0031] Such as figure 1 As shown, the lifting device of this embodiment includes a liftable installation part 1, on which a suspension hook 2 and a lock catch 3 are hinged, and the lock catch 3 is located above the suspension hook 2, and the suspension hook 2 and the lock catch 3 are both It can rotate around the hinge point in the vertical plane. The lock catch 3 is provided with a first buckle part 31, and the upper end of the hook 2 is provided with a second buckle part 21 that cooperates with the first buckle part 31. The lock buckle 3 It can be rotated to the non-working position where the first buckle 31 is away from the hook 2, or to the working position where the first buckle 31 is close to the hook 2. When the lock 3 is in the working position, the hook 2 can face the lock 3 Rotate until the first buckle part 31 and the second buckle part 21 are fastened together; specifically, the end of the upper surface of the hook 2 away from the lock buckle 3 is recessed downward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com