Robots for inspection of tubular structures

A tubular structure and robot technology, applied in the direction of pipe components, special pipes, mechanical equipment, etc., can solve the problems of complex devices, poor balance, and inability to adapt to vertical or inclined pipeline inspections, so as to improve efficiency and inspection Easy, reduces the possible effect of getting stuck in a bend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

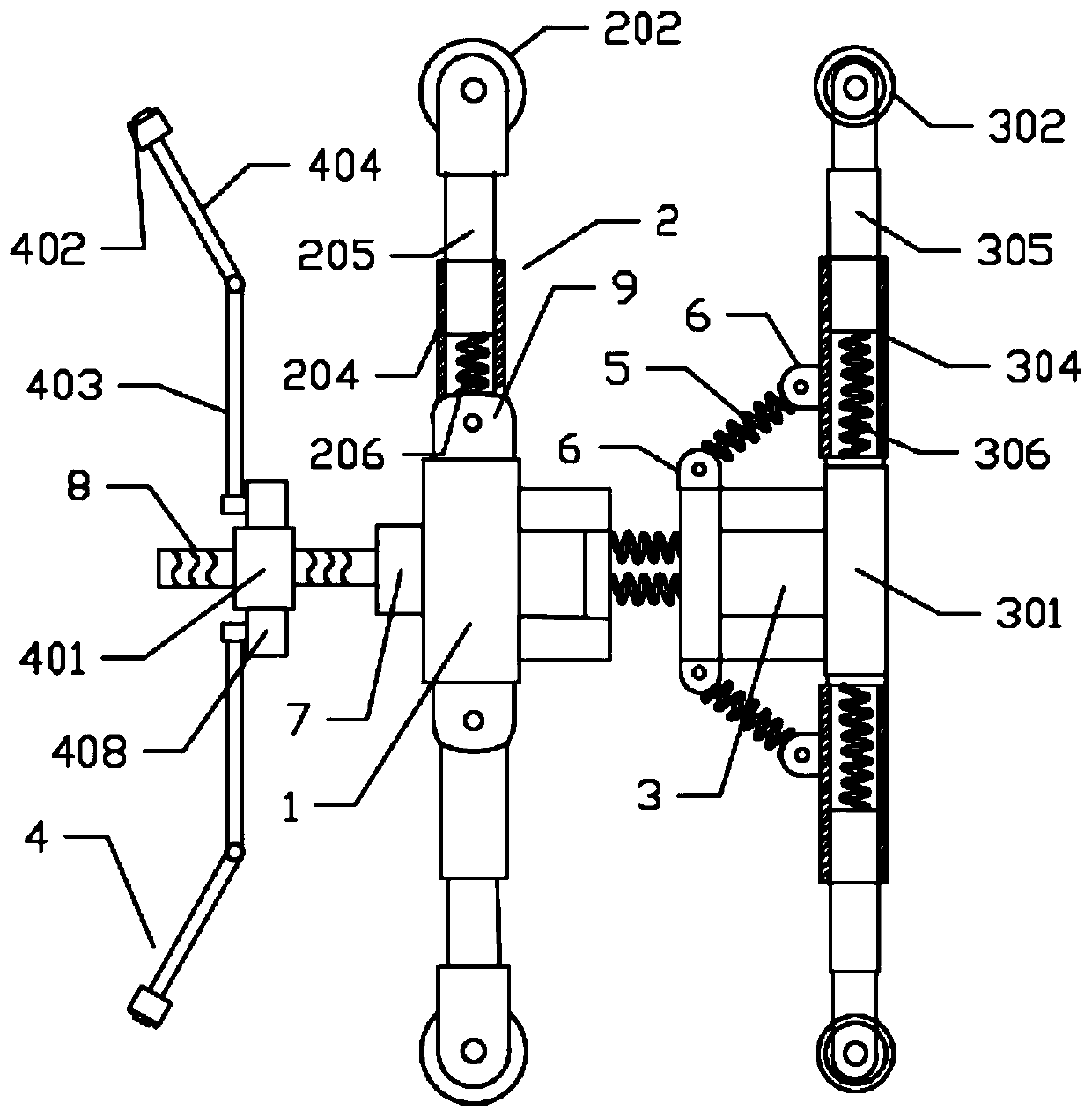

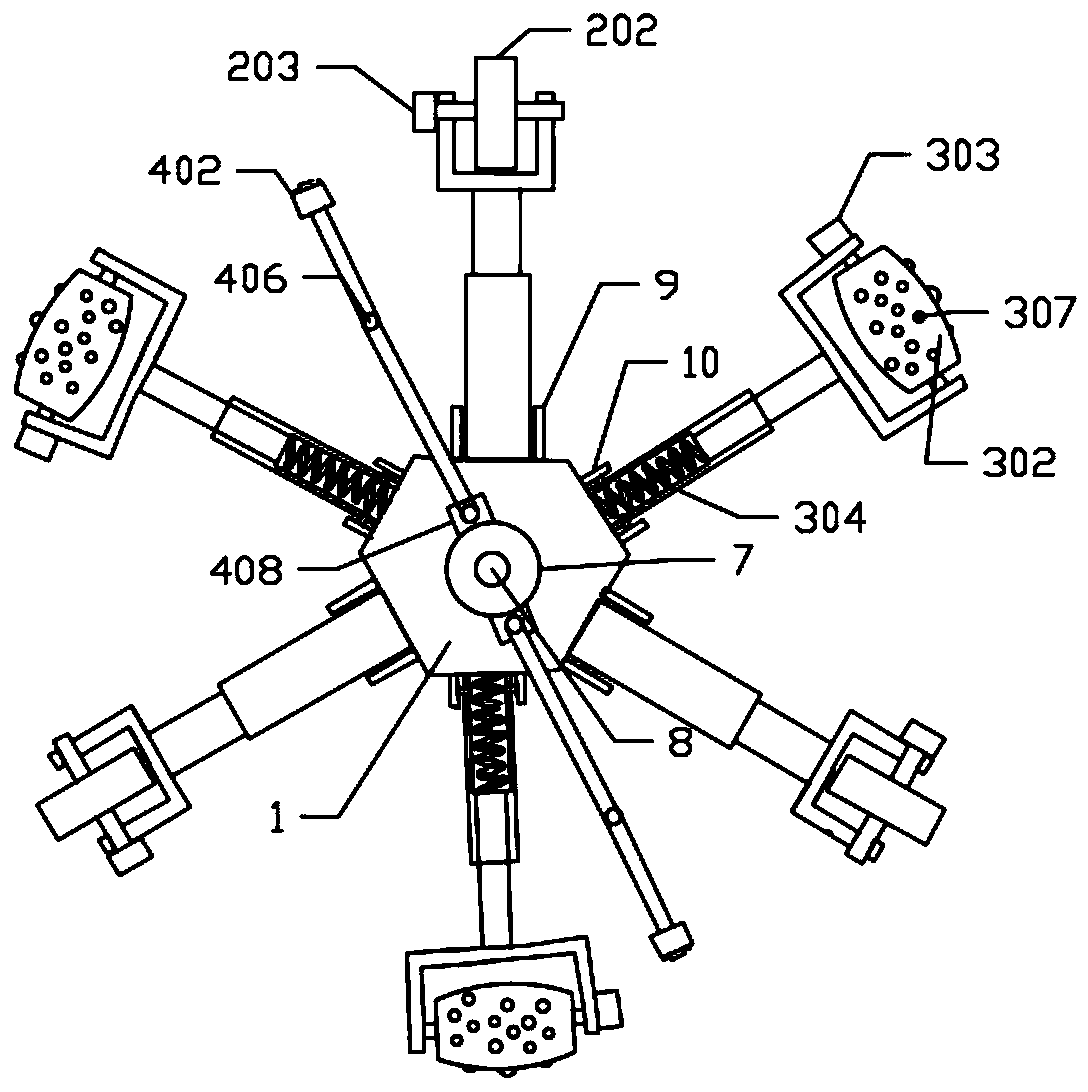

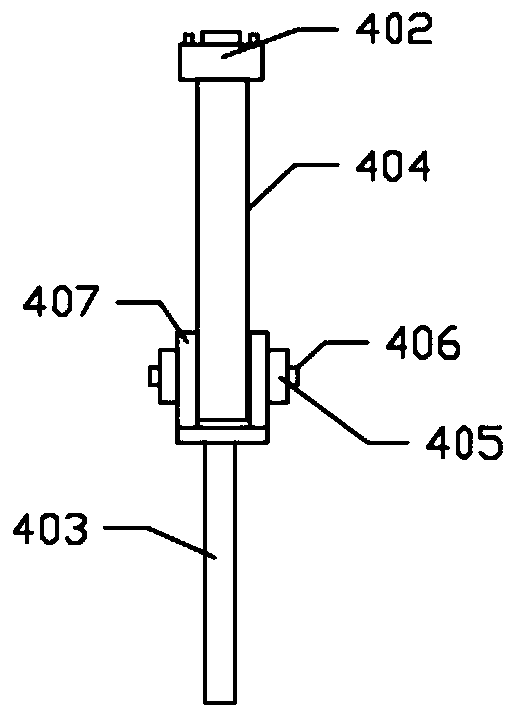

[0024] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 side view, image 3 Schematic diagram of the connecting rod structure. The robot for tubular structure inspection of the present invention includes a body 1 and an action mechanism 2 connected to the body 1, an attachment mechanism 3, and a detection mechanism 4. The action mechanism 2 includes at least three action mechanisms uniformly arranged in the circumferential direction of the body 1 Wheel 202, the attachment mechanism 3 includes a bracket 301, at least three attachment wheels 302 uniformly arranged in the circumferential direction of the bracket 301, and a first motor 303 for driving the rotation of the attachment wheels 302, the bracket 301 and the body 1 Flexible connection, the attachment wheel 302 is connected with the brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com