Heat exchange steam condensed water recovery device for drying tank

A technology of steam condensate and recovery device, which is applied in the direction of steam/steam condenser, filter circuit, lighting and heating equipment, etc. It can solve the problems of silk quality influence, poor quality of oil agent, and low cleanliness of condensate water, and achieve saving The effect of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail the following examples, but the descriptions of the examples are not intended to limit the solutions of the present invention. Equivalent transformations that are only formal but not substantive should be regarded as the scope of the technical solution of the present invention.

[0019] In the following descriptions, all concepts related to directionality or orientation of up, down, left, right, front and rear are based on figure 1 In terms of the current position and state, it cannot be understood as a special limitation on the technical solution provided by the present invention.

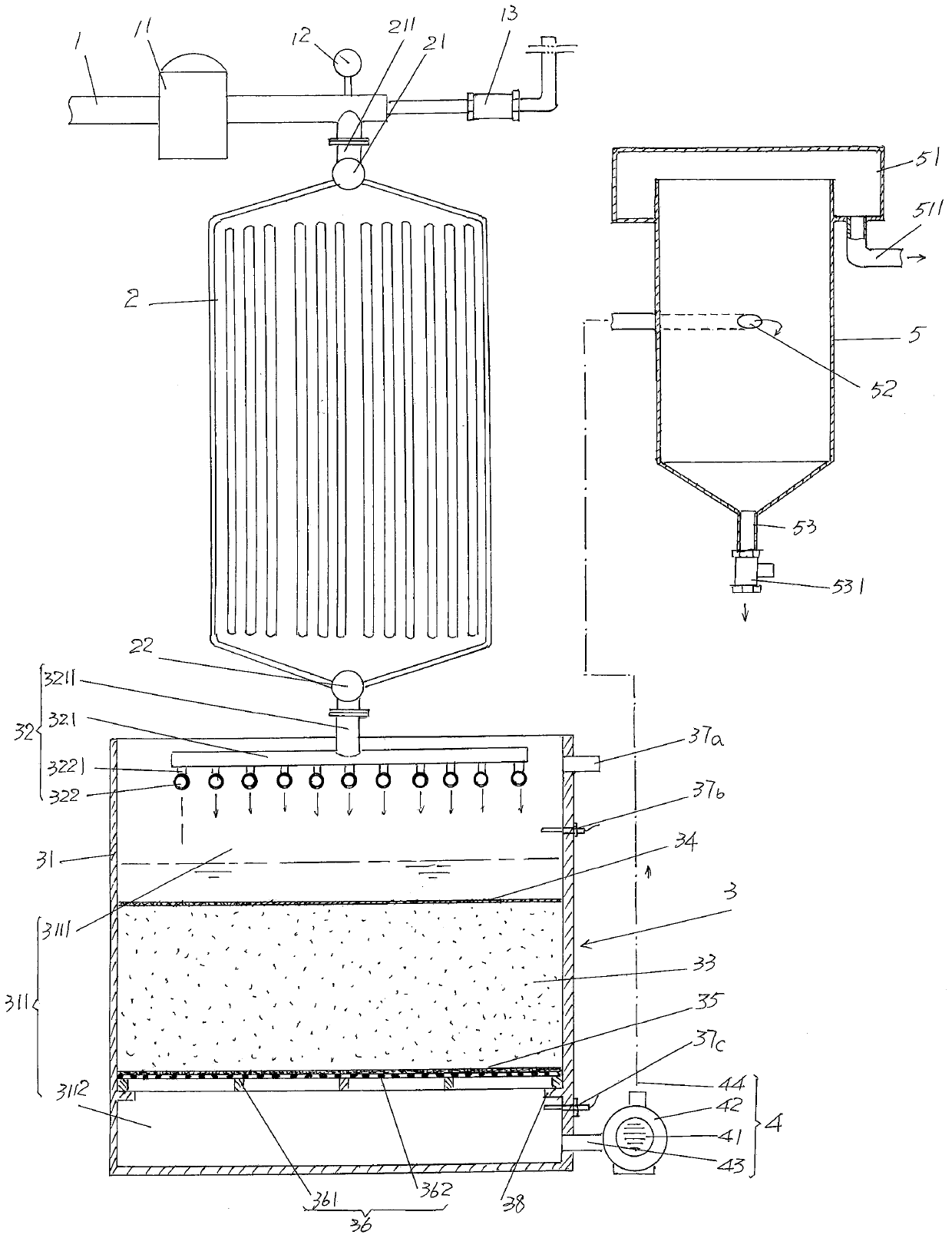

[0020] See figure 1 , shows a steam recovery pipe 1 and a radiator 2, one end of the steam recovery pipe 1 is connected to the jacket steam outlet of the drying tank (not shown in the figure), and a steam trap is arranged at the other end from lef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap