Measuring method for left-right skew swing state of rolling bearing roller

A technology of rolling bearings and measurement methods, which is applied in the directions of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as insufficient effective acquisition of roller skew data, difficulty in measurement, small amount of roller skew, etc. To achieve the effect of avoiding disasters and accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

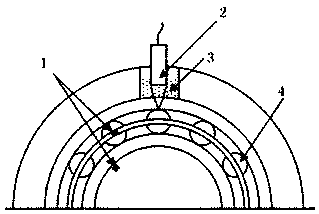

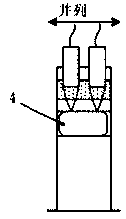

[0043] see figure 1 and figure 2, is a schematic diagram of parallel installation of dual-focus ultrasonic sensors in this example of the present invention, wherein 1 is a reflective sheet, 2 is an ultrasonic sensor, 3 is a coupling agent, and 4 is a roller. Two ultrasonic sensor probes are installed side by side along the length direction of the roller directly above the outer ring of the rolling bearing. To ensure good coupling conditions between the transmitting end face of the ultrasonic sensor and the surface of the outer ring of the rolling bearing, two ultrasonic sensors are installed side by side for measurement, and the reflectivity R of the ultrasonic signal is obtained by focusing the ultrasonic sensor at high frequency. According to the time difference of the minimum reflectivity respectively obtained by the two ultrasonic sensors, the left and right tilting state of the roller is determined. Assuming that the revolution speed of the roller is ν, the number of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com