Method for heating control of food processor and food processor

A heating control and cooking machine technology, applied in kitchen utensils, household utensils, applications, etc., can solve the problems of easy boiling overflow, inaccurate determination of boiling point, and different boiling points, so as to achieve accurate determination of boiling point, shorten food preparation time, and prevent boiling overflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

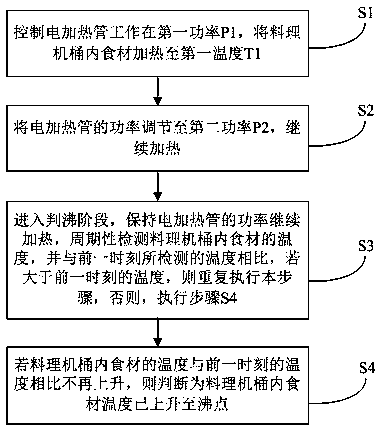

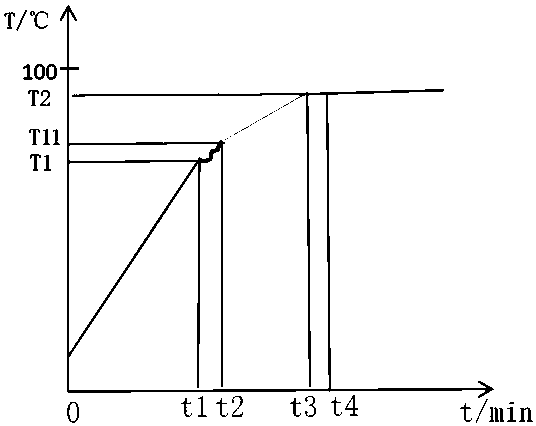

[0035] Embodiment 1, the boiling point of the heating liquid is different at different altitudes, and the higher the altitude, the lower the boiling point. Taking water as an example, when the altitude is 0 (1 standard atmospheric pressure), the boiling point is 100°C; when the altitude is 1000m, the boiling point is about 97°C; when the altitude is 2000m, the boiling point is about 93°C. At present, the heating program of the cooking machine, such as soybean milk, rice paste, etc., is usually set according to the boiling point (such as 97°C) at low altitude (below 1000m), which is not compatible with high altitude areas (above 1000m); when used in high altitude areas ( When used above 1000m), due to the relatively low boiling point, it cannot reach the boiling point (such as 97°C) set in the program for low altitudes (below 1000m), so the machine keeps heating, resulting in overflow, resulting in extremely poor user experience.

[0036] The present invention aims to determine...

Embodiment 2

[0064] Embodiment 2, this embodiment proposes a cooking machine, the cooking machine has at least a cooking machine barrel for holding ingredients, and an electric heating tube for heating the ingredients in the barrel, the cooking machine according to the first embodiment The heating control method of the cooking machine described executes heating control, for details, please refer to Embodiment 1 and Figure 1-Figure 3 records, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com