High-pressure hydrate generation device applicable to neutron diffraction

A high-pressure generation and hydrate technology, which is applied in the direction of measuring devices, material analysis using wave/particle radiation, and methods of chemically changing substances using atmospheric pressure. It can solve the problem of limited sample cavity size and neutron beam intensity. The requirements are very high, and it is not suitable for problems such as hydrate formation reaction and in-situ observation, so as to achieve the effect of preventing background

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

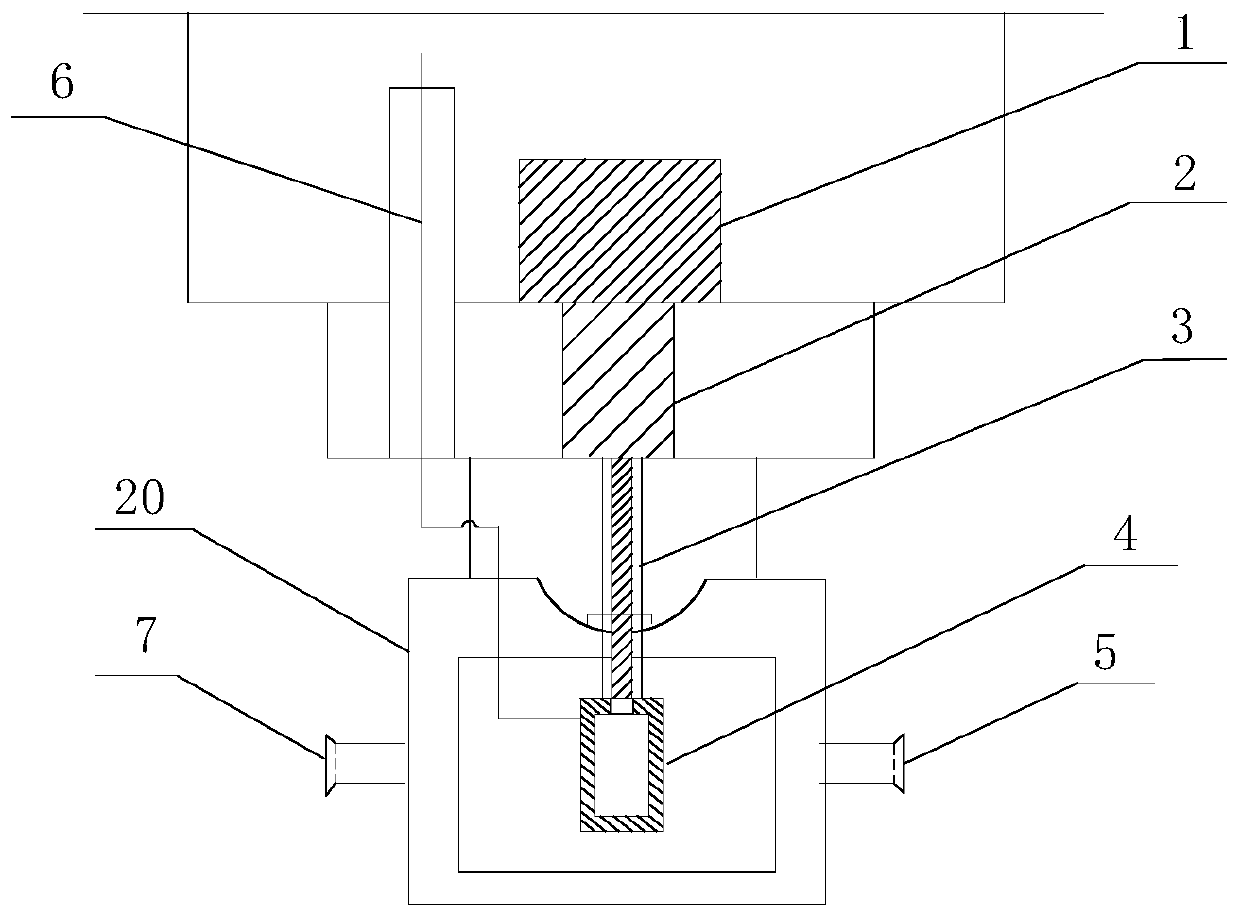

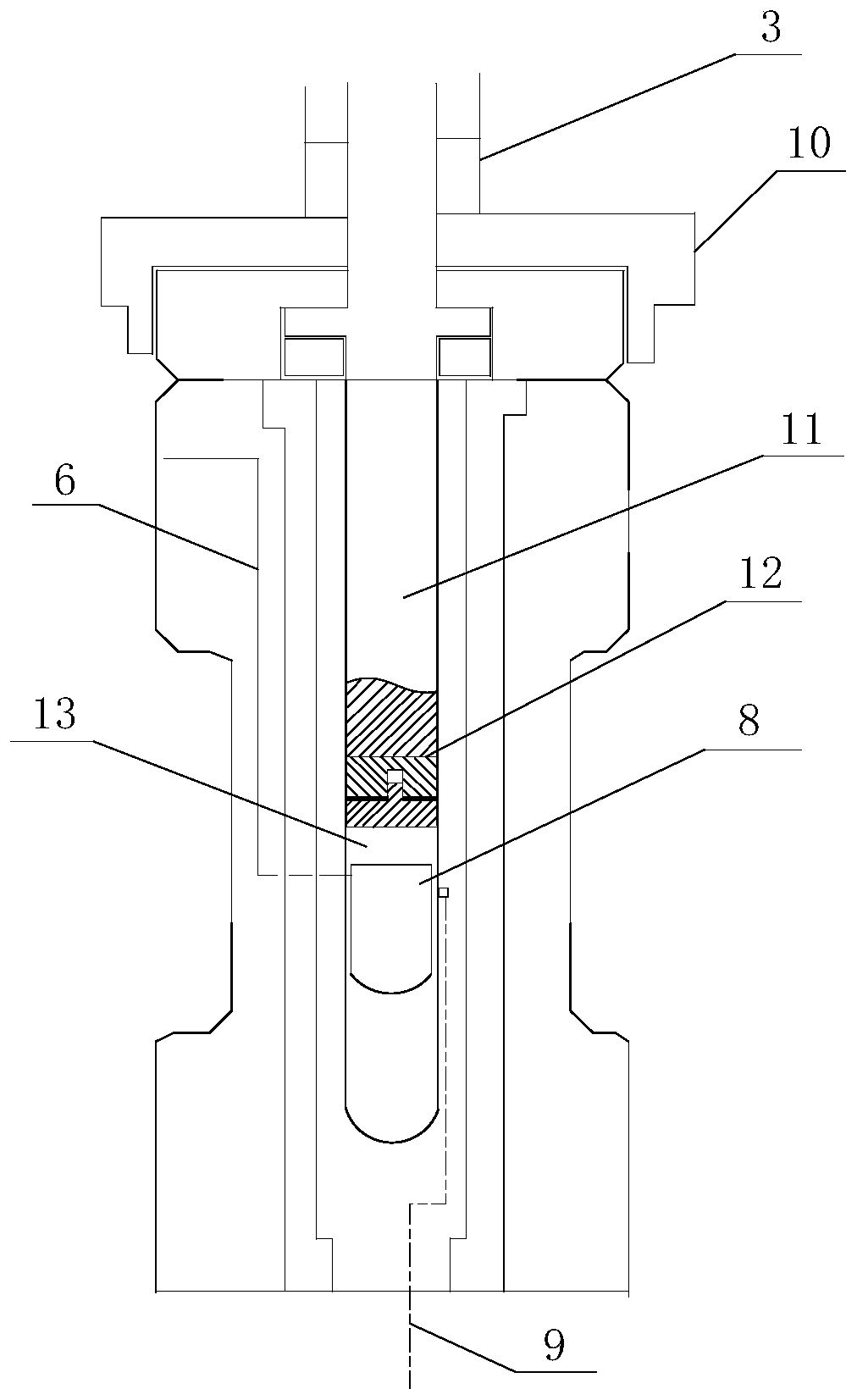

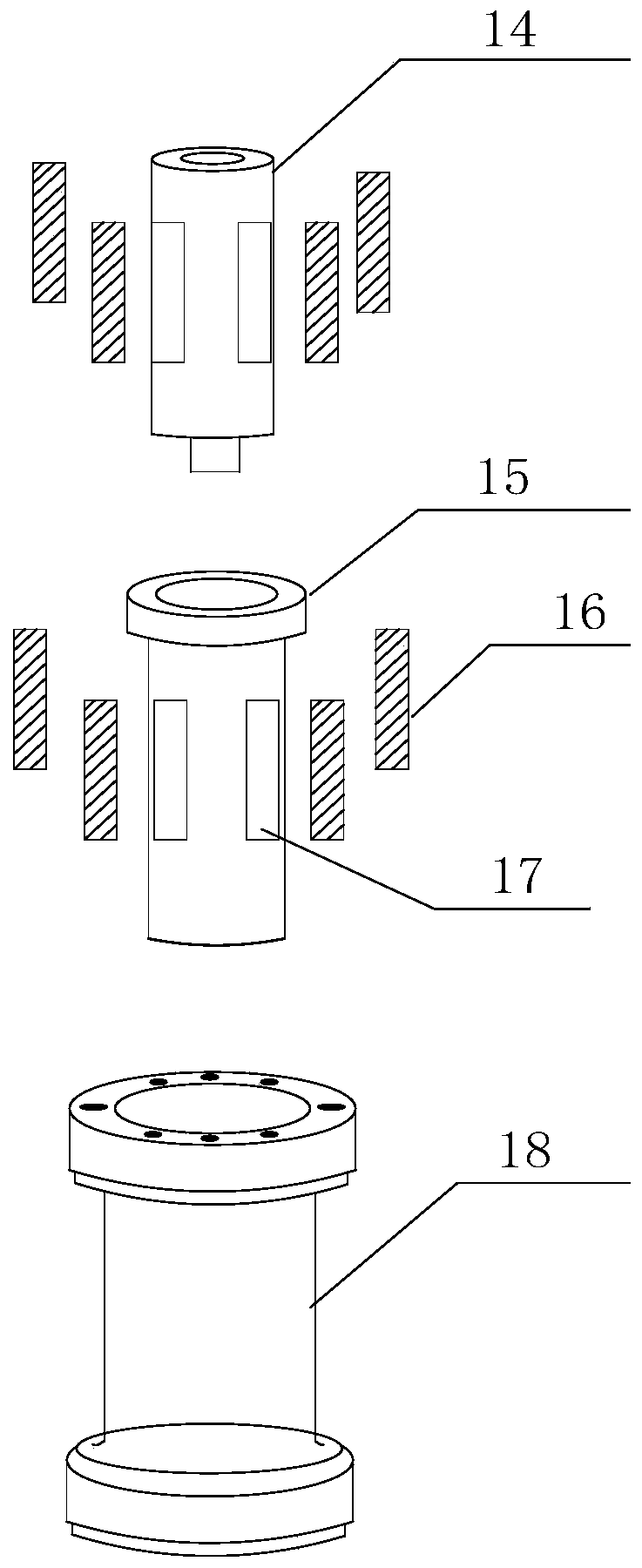

[0031] Such as Figure 1 to Figure 4 As shown, a neutron diffraction hydrate high-pressure generating device mainly includes a temperature loading system 1, a pressure loading device 2, a rotating mechanism 3, a hydrate reactor 4, an incident window 5, an air inlet pipeline 6, an exit window 7 and Hydrate sample chamber 8.

[0032] The temperature loading system 1 is used to create a low-temperature environment for the formation reaction of hydrates. The hydrate reactor 4 is placed inside its matching temperature control chamber 20. The temperature loading system 1 adopts dual control of open-loop liquid nitrogen refrigeration cycle and air bath cycle. mode, the temperature control range is 100K~310K, and the temperature control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com