Waste lithium battery flushing equipment

A technology for waste lithium batteries and equipment, which is applied in chemical instruments and methods, cleaning methods and utensils, and cleaning methods using liquids, etc., can solve the problems of more waste of water resources and increased recycling costs, and avoid water accumulation and save energy. time, work clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

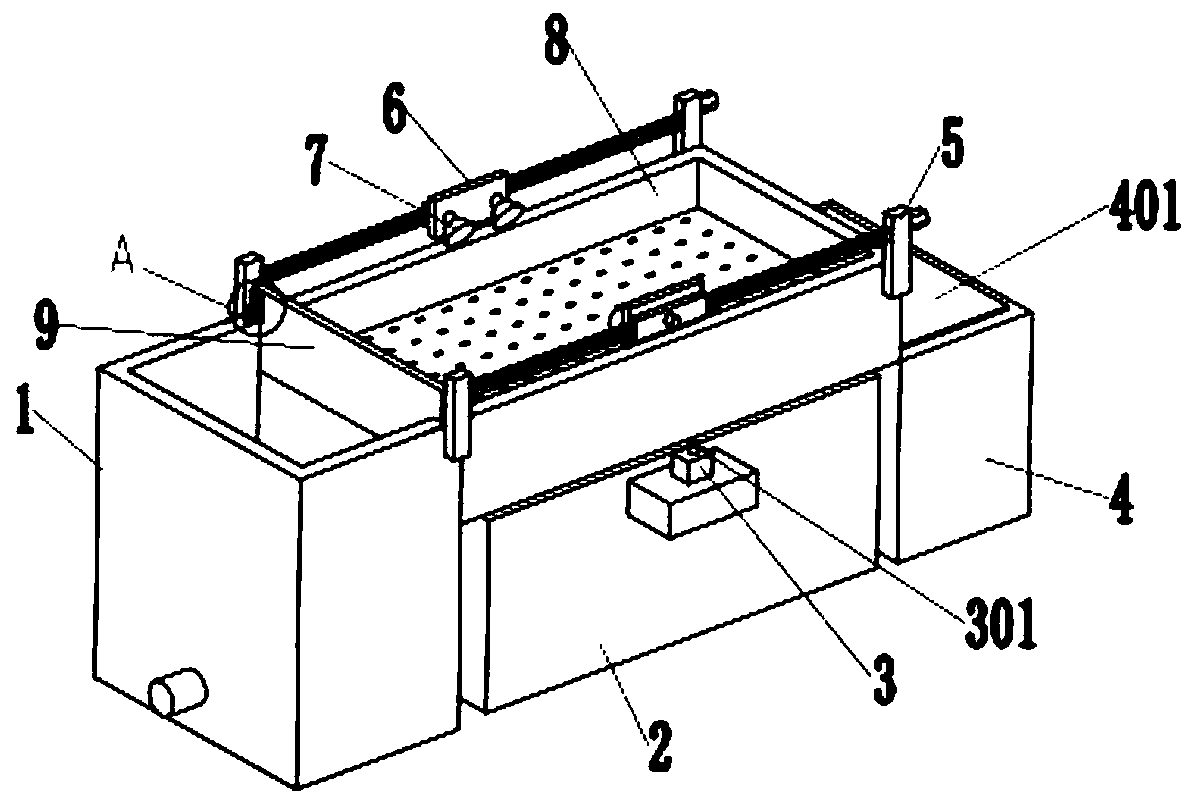

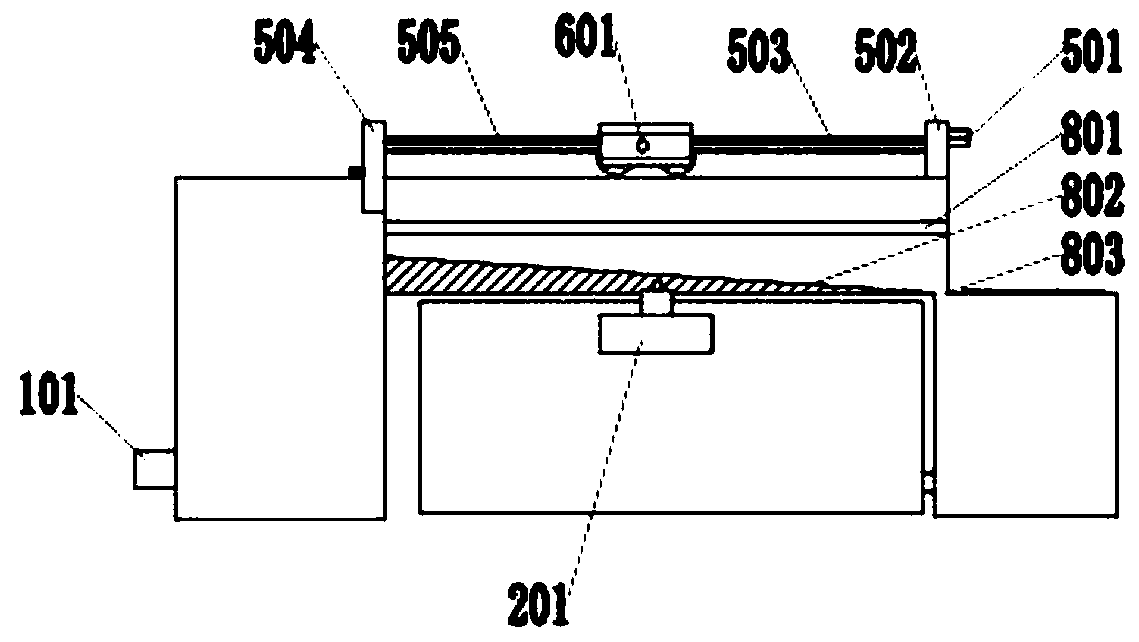

[0029] Such as figure 1 As shown, a waste lithium battery washing equipment includes a sludge collection tank 1, a water supply tank 2, a collection water tank 4, a driving device 5, and a cleaning tank 8, and sludge collection tanks 1 are respectively arranged on both sides of the cleaning tank 8. , collecting water tank 4, cleaning tank 8 communicates with sludge collecting tank 1 and collecting water tank 4, and baffle plate 9 is provided between cleaning tank 8 and sludge collecting tank 1, and sieve plate 801 is provided in the described cleaning tank 8, so Both sides of the cleaning box 8 are provided with a driving device 5, the driving device 5 is provided with a slide block 6, the slide block 6 is provided with a nozzle 7, and the nozzle 7 communicates with the water supply tank 2 through the water pump 3, The water supply tank 2 is arranged below the cleaning tank 8 , and the water supply tank 2 communicates with the collection water tank 4 .

Embodiment 2

[0031] Such as figure 1 As shown, a waste lithium battery washing equipment includes a sludge collection tank 1, a water supply tank 2, a collection water tank 4, a driving device 5, and a cleaning tank 8, and sludge collection tanks 1 are respectively arranged on both sides of the cleaning tank 8. , collecting water tank 4, cleaning tank 8 communicates with sludge collecting tank 1 and collecting water tank 4, and baffle plate 9 is provided between cleaning tank 8 and sludge collecting tank 1, and sieve plate 801 is provided in the described cleaning tank 8, so Both sides of the cleaning box 8 are provided with a driving device 5, the driving device 5 is provided with a slide block 6, the slide block 6 is provided with a nozzle 7, and the nozzle 7 communicates with the water supply tank 2 through the water pump 3, The water supply tank 2 is arranged below the cleaning tank 8 , and the water supply tank 2 communicates with the collection water tank 4 .

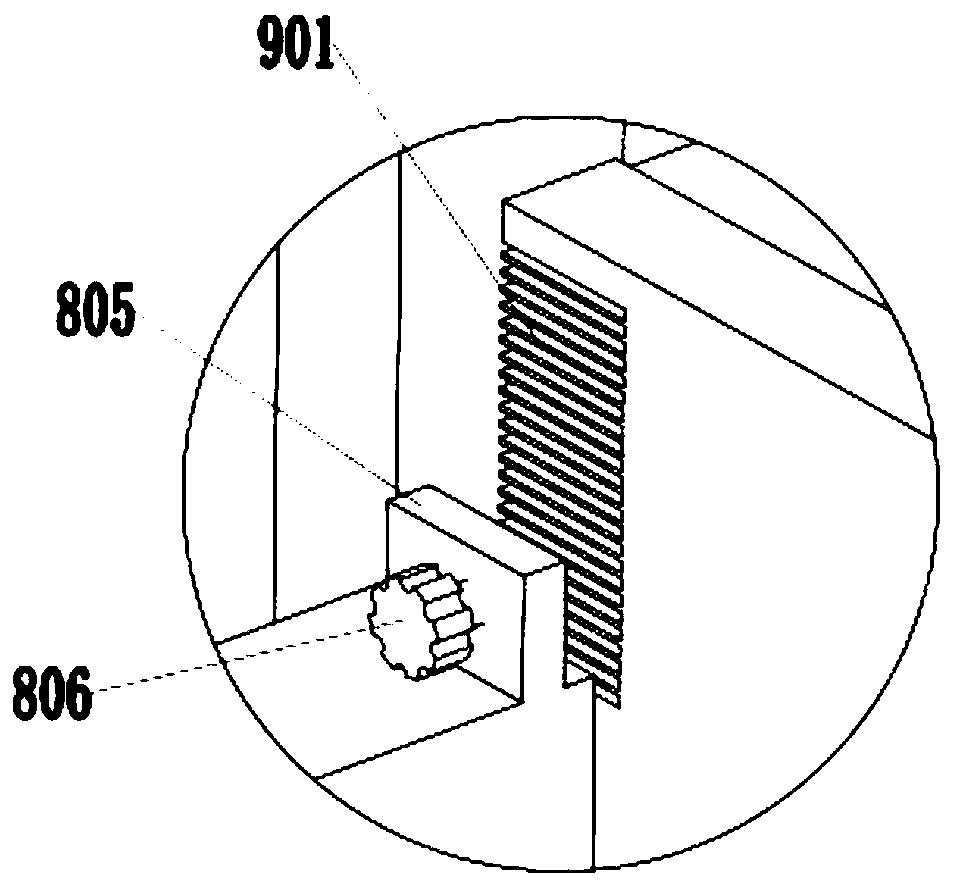

[0032] Such as imag...

Embodiment 3

[0034] Such as figure 1 As shown, a waste lithium battery washing equipment includes a sludge collection tank 1, a water supply tank 2, a collection water tank 4, a driving device 5, and a cleaning tank 8, and sludge collection tanks 1 are respectively arranged on both sides of the cleaning tank 8. , collecting water tank 4, cleaning tank 8 communicates with sludge collecting tank 1 and collecting water tank 4, and baffle plate 9 is provided between cleaning tank 8 and sludge collecting tank 1, and sieve plate 801 is provided in the described cleaning tank 8, so Both sides of the cleaning box 8 are provided with a driving device 5, the driving device 5 is provided with a slide block 6, the slide block 6 is provided with a nozzle 7, and the nozzle 7 communicates with the water supply tank 2 through the water pump 3, The water supply tank 2 is arranged below the cleaning tank 8 , and the water supply tank 2 communicates with the collection water tank 4 .

[0035] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com