A kind of manufacturing process of nylon fiber polishing wheel

A nylon fiber and manufacturing process technology, which is applied to the manufacturing process field of nylon fiber polishing wheels, can solve problems such as a large number of residual materials, and achieve the effects of high utilization rate of raw materials, reduction of production costs, and improvement of market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] A kind of manufacture craft of nylon fiber polishing wheel of the present invention, comprises the following steps:

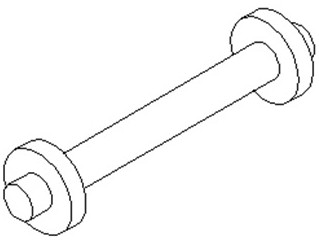

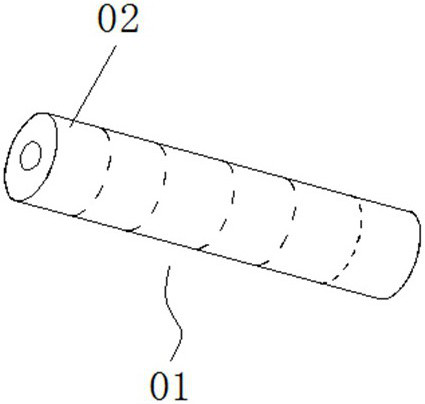

[0020] (1) Place a rotatable mandrel film: in the workshop, set a rotatable film such as figure 2 As shown in the mandrel film, the outer diameter of the mandrel film is compatible with the inner diameter of the nylon polishing wheel to be made, and the outer peripheral surface of the mandrel film is coated with wax for easy demoulding;

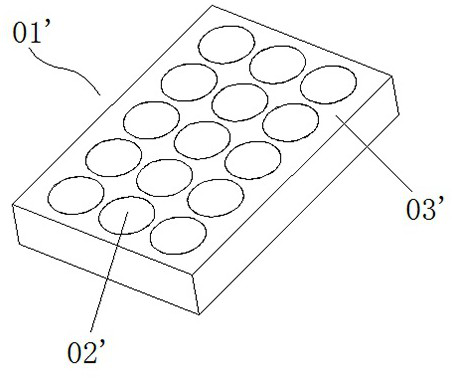

[0021] In order to ensure the flatness of both ends of the subsequent nylon fiber polishing wheel blank, the two ends of the mandrel film are detachably connected with a limit stop disc, and the limit stop disc is also coated on the contact surface with the polishing collodion. Wax for easy demoulding; another function of the limit stop disc is to prevent deviation when the polishing collodion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com