Internal mixer energy efficiency improvement and protection system

A protection system and internal mixer technology, applied in the field of internal mixer systems, can solve the problems of large motor damage, reduced motor service life, and very large motor resistance, and achieve the effect of convenient accountability and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

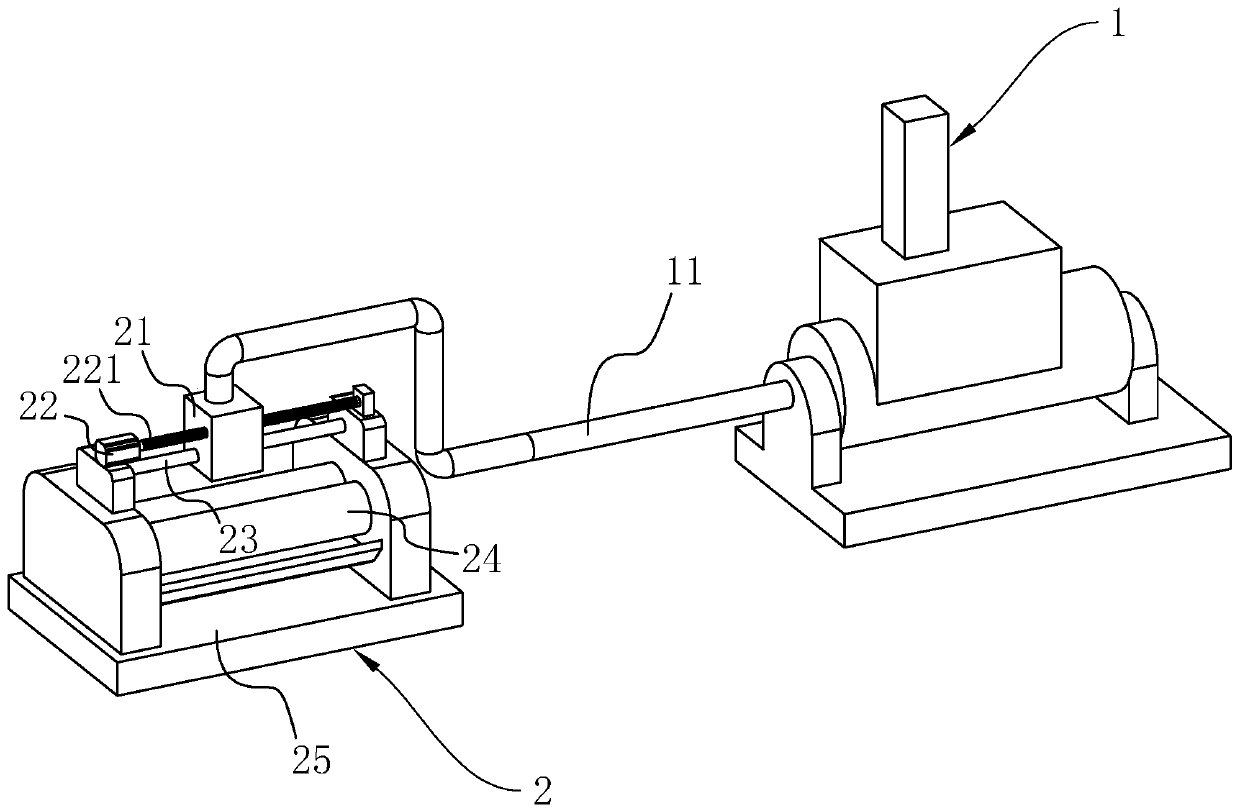

[0054] Embodiment: a kind of internal mixer 1 can put and protect system, as figure 1 As shown, it includes an internal mixer 1 and an open mixer 2 arranged near the internal mixer 1 . The internal mixer 1 is fixedly connected with a transmission pipeline 11 , and the other end of the transmission pipeline 11 is connected to the open mixer 2 . The transfer line 11 is a hose. The rubber raw material produced by the internal mixer 1 flows to the open mill 2 through the transmission pipeline 11, and is processed by the open mill 2 to produce strip-shaped rubber.

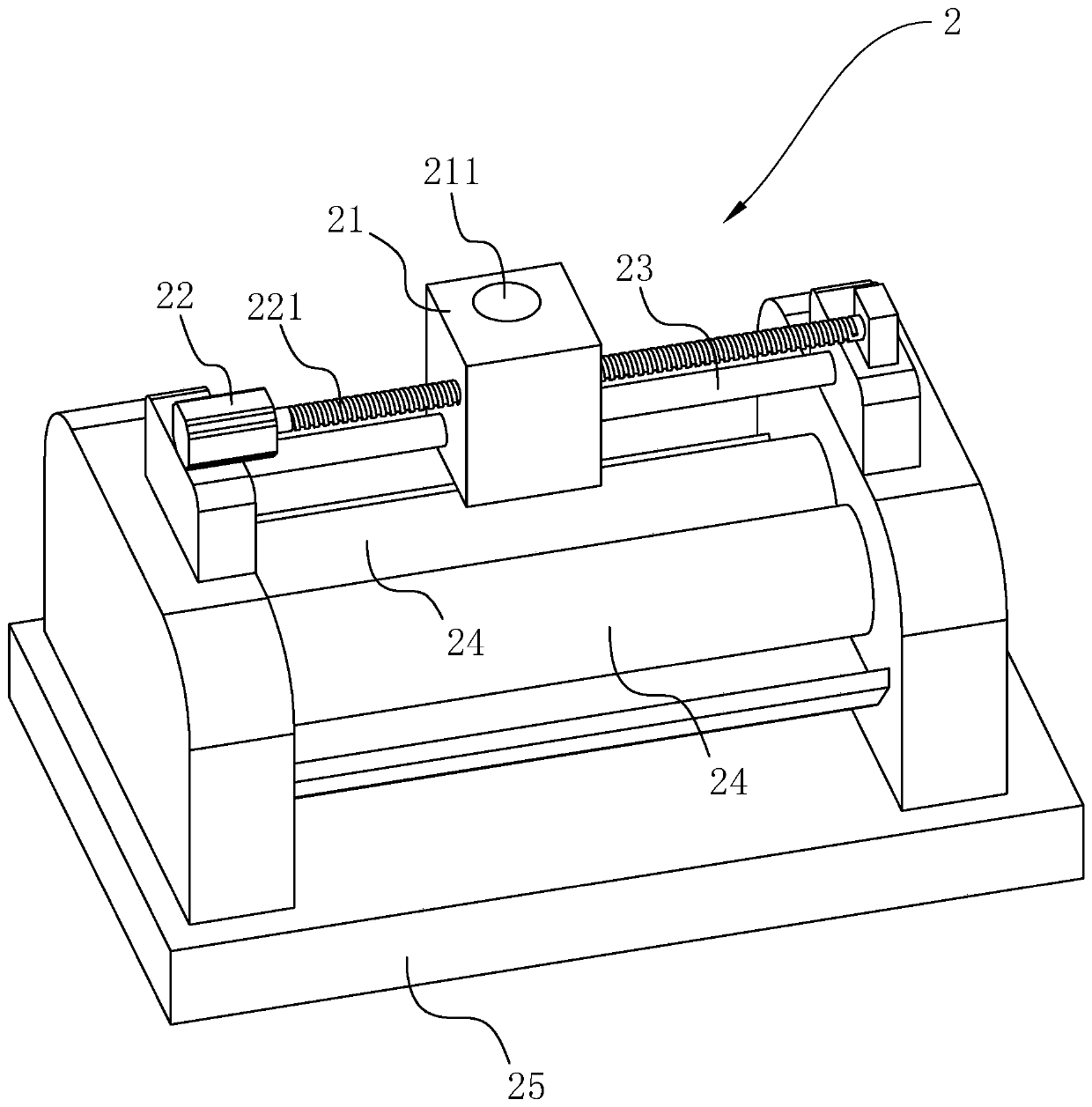

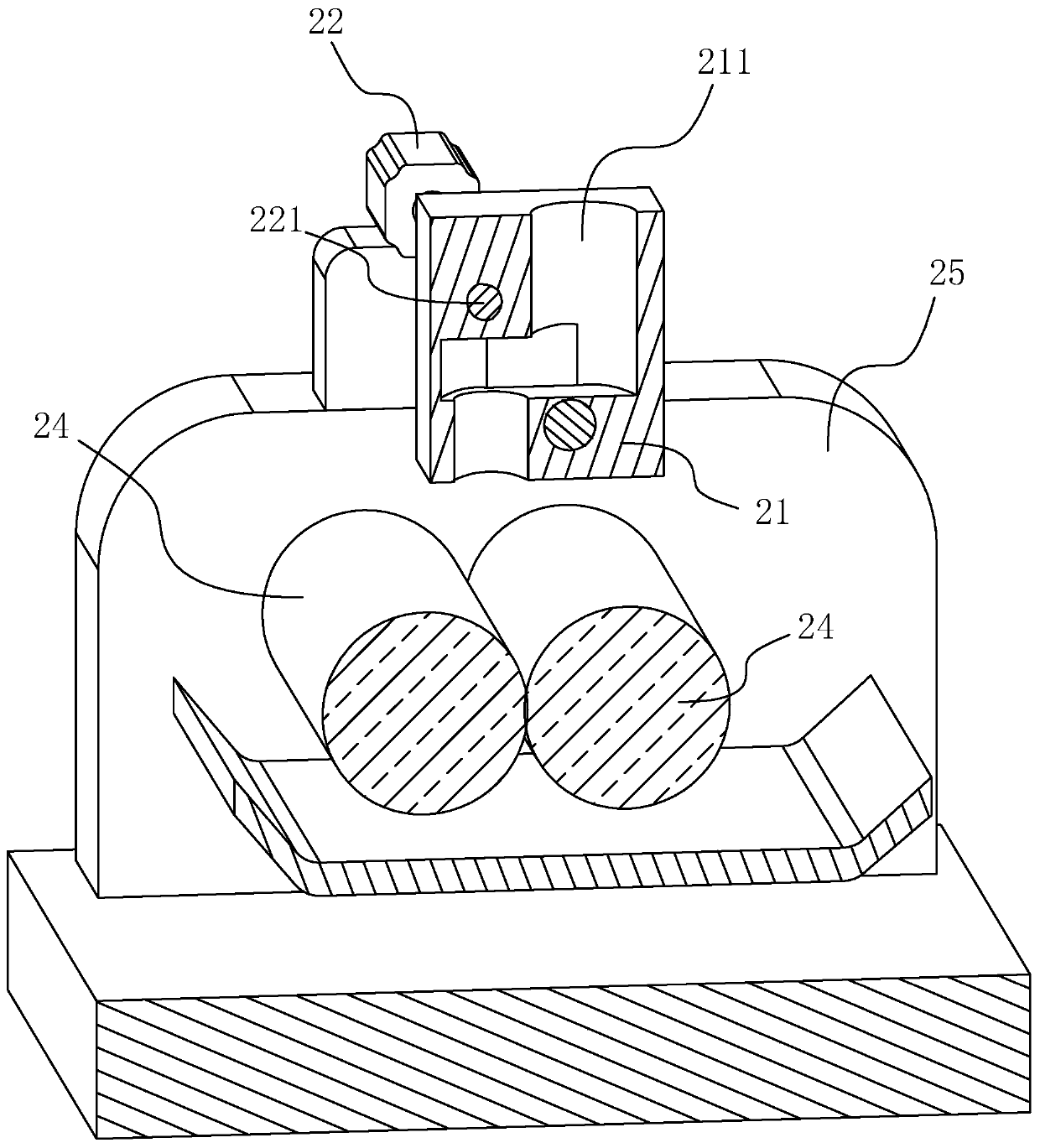

[0055] Such as figure 2 and image 3 As shown, the mill 2 includes a fuselage 25 on which two extruding rollers 24 arranged parallel to each other are rotatably connected, and the two extruding rollers 24 are close to each other and can rotate in opposite directions. A blanking block 21 is arranged at the position directly above the fuselage 25 corresponding to the two extrusion rollers 24, and a guide post 23 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com