A breathable mast for fsru

A technology for masts and breathable caps, applied in the direction of masts, superstructures, ship construction, etc., can solve the problems of increasing the exhaust gas discharge height and inconvenient installation of exhaust gas discharge devices, so as to increase the exhaust gas discharge height, prevent the exhaust gas from harming the crew, and facilitate the discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

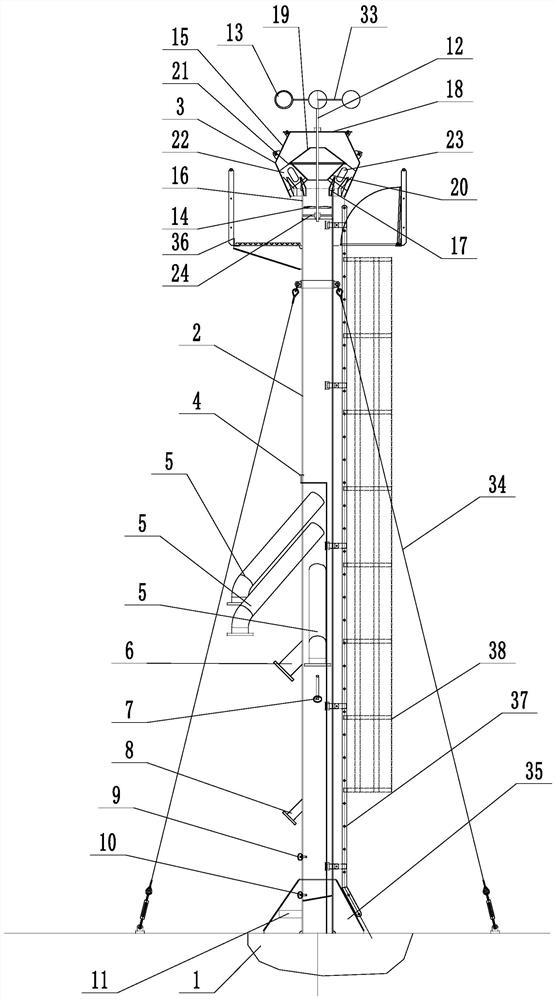

[0023] Example 1: A breathable mast suitable for FSRU (see attached figure 1 , Attached Figure 4 ), including the mast body 2 installed on the hull 1, the breathable cap 3 installed on the upper end of the mast body, the mast body has a tubular structure, and the mast body is provided with a gas sampling port 4, a liquid tank safety valve outlet pipe interface 5, and a liquid tank The steam release pipeline interface 6, the gas-water separator outlet pipe interface 7, the portable connection end interface 8, the nitrogen flushing pipeline interface 9, the drain pipe interface 10, and the liquid tank safety valve outlet pipe interface are provided with four. The gas sampling port, the liquid tank safety valve outlet pipe interface, the liquid tank vapor release pipe interface, the gas-water separator outlet pipe interface, the portable connection end interface, the nitrogen flushing pipe interface, and the drain pipe interface are arranged in order from top to bottom. The outer...

Embodiment 2

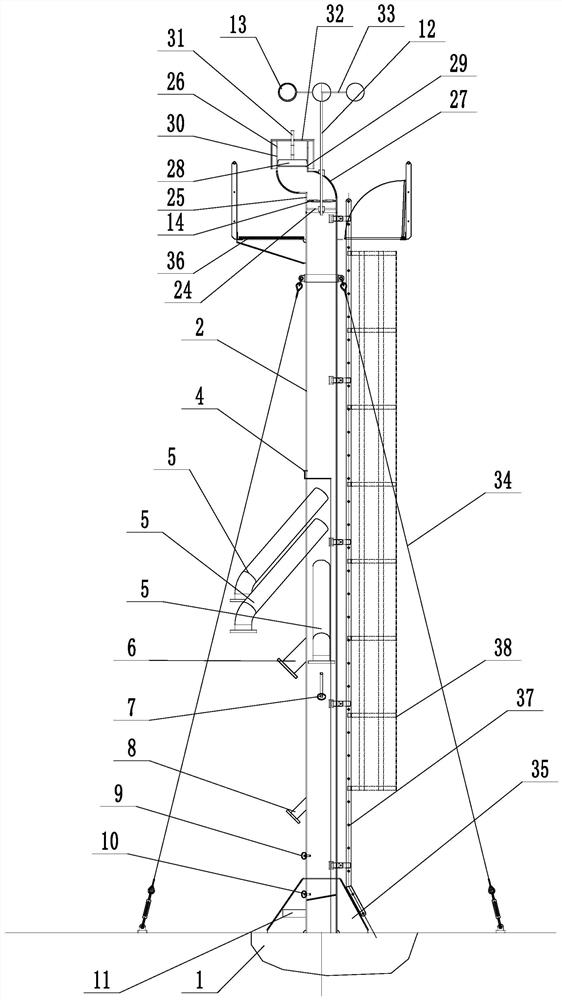

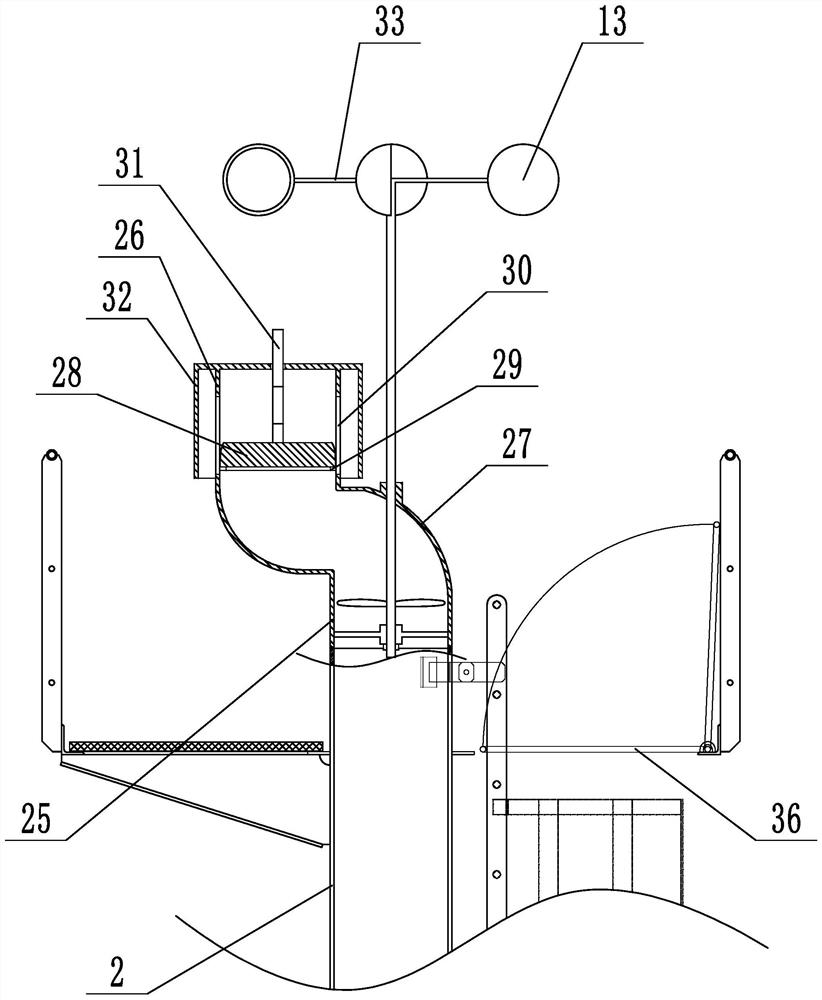

[0026] Example 2: A breathable mast suitable for FSRU (see attached figure 2 , Attached image 3 ), its structure is similar to embodiment 1, the main difference is that in this embodiment the breathable cap includes a connecting section 25, an air outlet section 26, an arc-shaped transition section 27 arranged between the connecting section and the air outlet section, and the exhaust blades are placed In the connecting section, the rotating shaft is rotatably installed on the transition section, and the push plug 28 that can move up and down is installed in the air outlet section. A number of support protrusions 29 are provided under the push plug on the inner wall of the air outlet section. A long strip of air outlet slot 30, push the plug to install the indicator rod 31, the indicator rod is green, yellow, and red from top to bottom. The upper end of the air outlet section is connected with a rain cap 32. The rain cap covers the air outlet section to prevent rain An air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com