A carbon fiber processing and discharging device

A discharge device and carbon fiber technology, applied in the direction of processing textile material equipment configuration, processing textile material drums, processing textile material carriers, etc., can solve the problems of waste, large labor force, uneven resin amount, etc., to improve the bonding rate, Improve adhesion and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A number of non-limiting embodiments of the present invention will now be described in detail with reference to the accompanying drawings. The embodiments designed in this description are only used to explain the principle of the present invention and not limit the protection scope of the present invention.

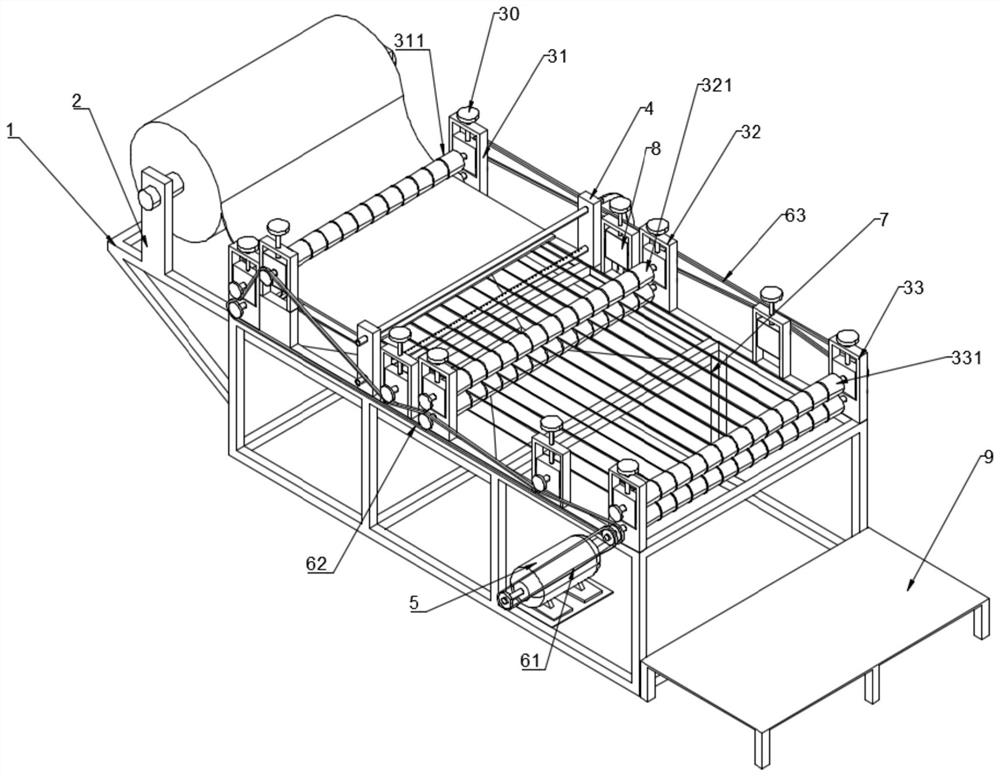

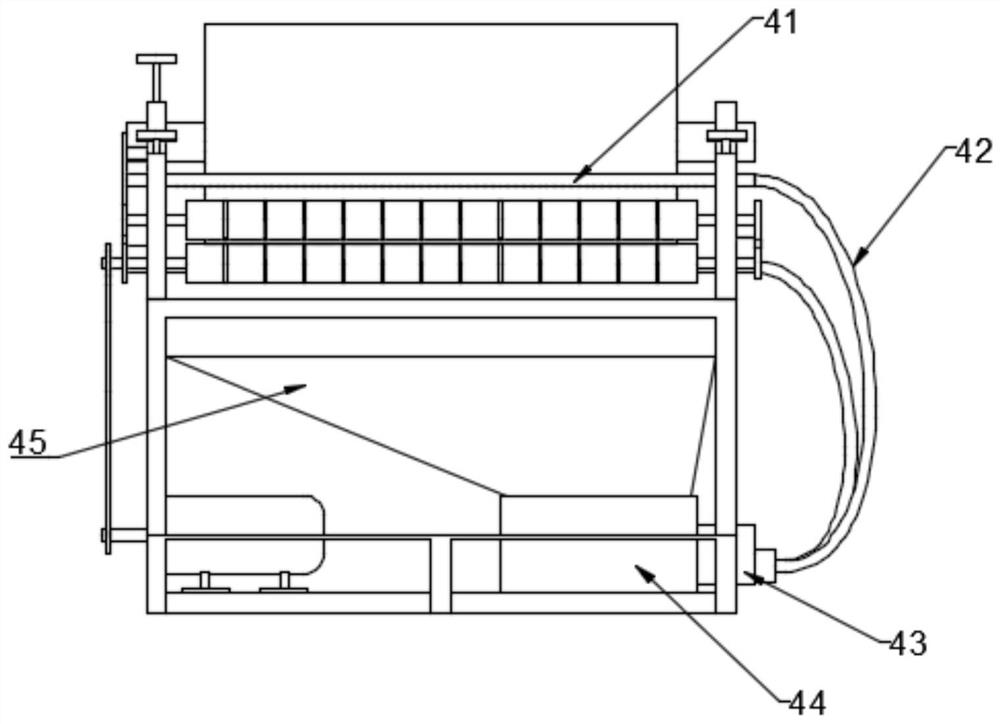

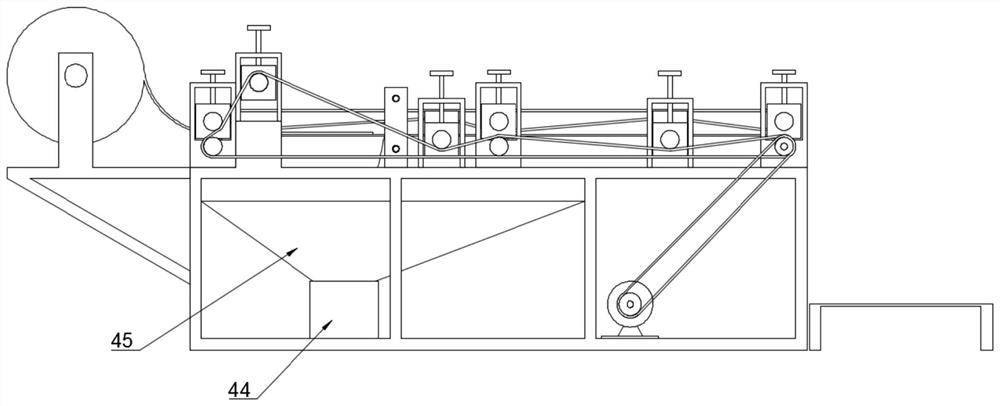

[0021] This embodiment relates to a carbon fiber processing and discharging device. The composition and structure of the processing and discharging device are as follows: Figure 1-Figure 3 As shown, a carbon fiber processing discharge device is characterized in that it includes a frame 1, an extruding device, a grease spraying device 4 and a feeding device, and the grease spraying device 4 is located in the middle of the frame 1, and it includes a frame fixed on The grease injection pipe 41 that is provided with a plurality of injection holes on the frame 1, is fixed on the bottom of the frame 1 and is externally connected with the resin tank 44 of the water pump 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com