Printing and dyeing equipment for polyester textile fabric

A technology of textile fabrics and printing and dyeing equipment, which is applied in the field of textile fabric printing and dyeing, which can solve the problems of uneven printing and dyeing, inability to apply polyester and knitted fabrics, and fabric deformation, so as to improve the brightness of color, prevent detachment from deformation, and speed up dissolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

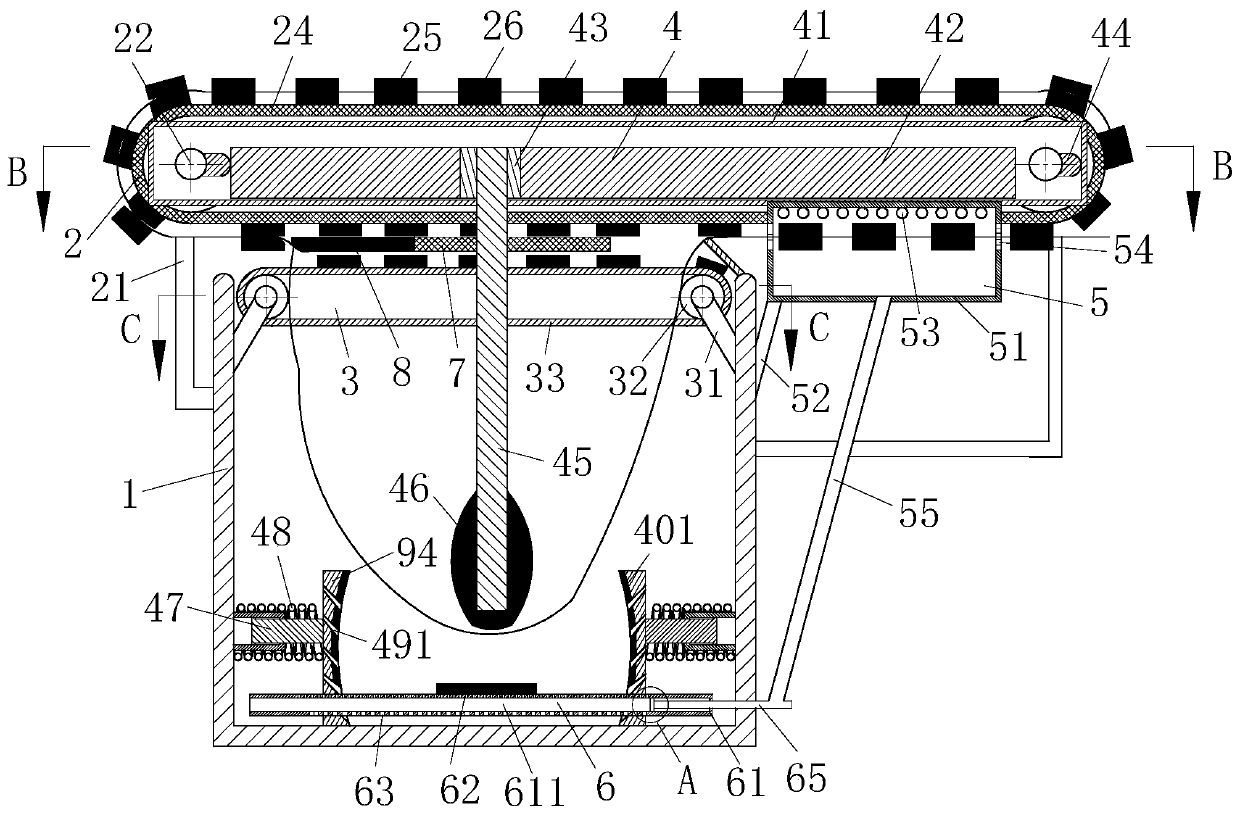

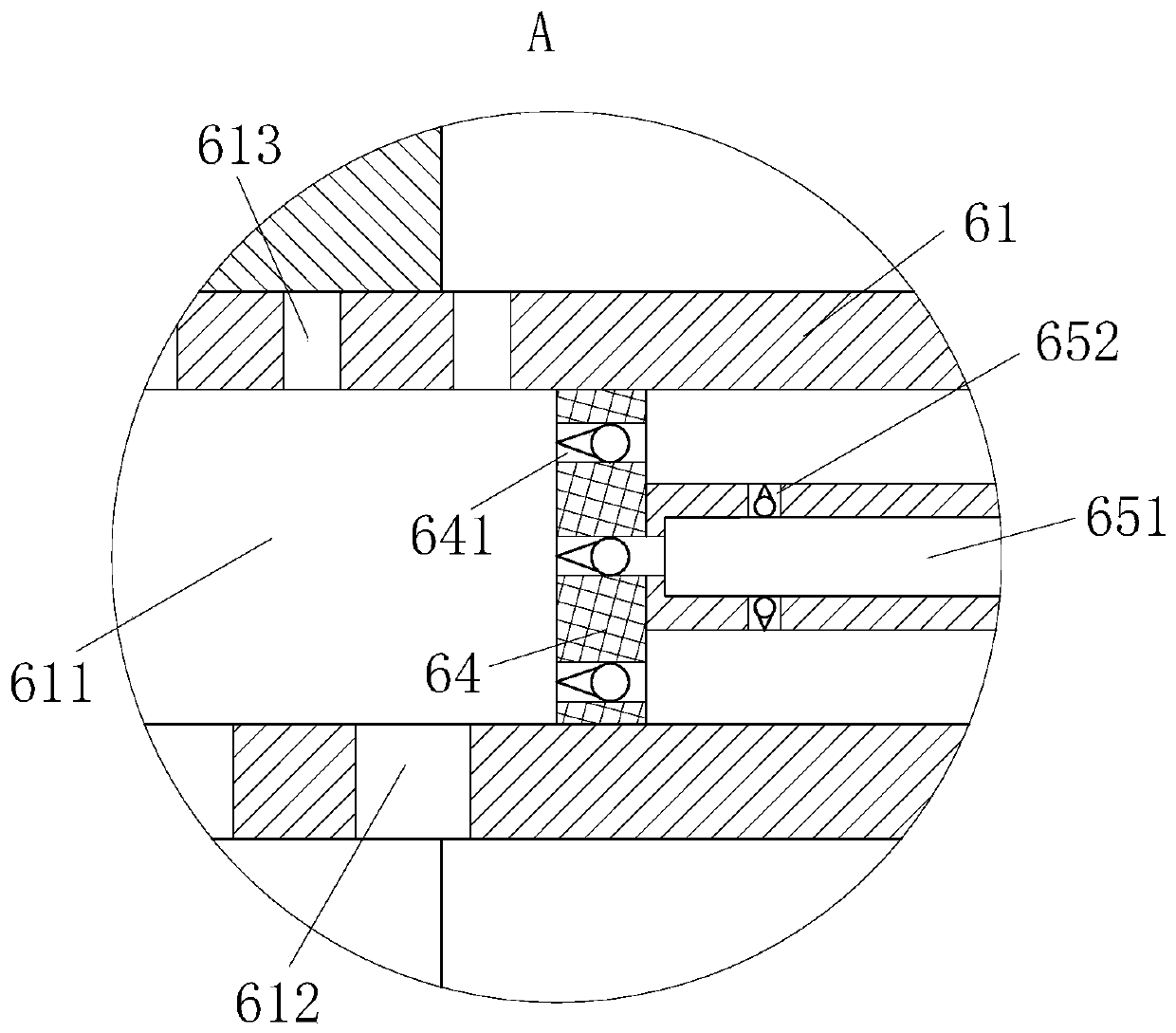

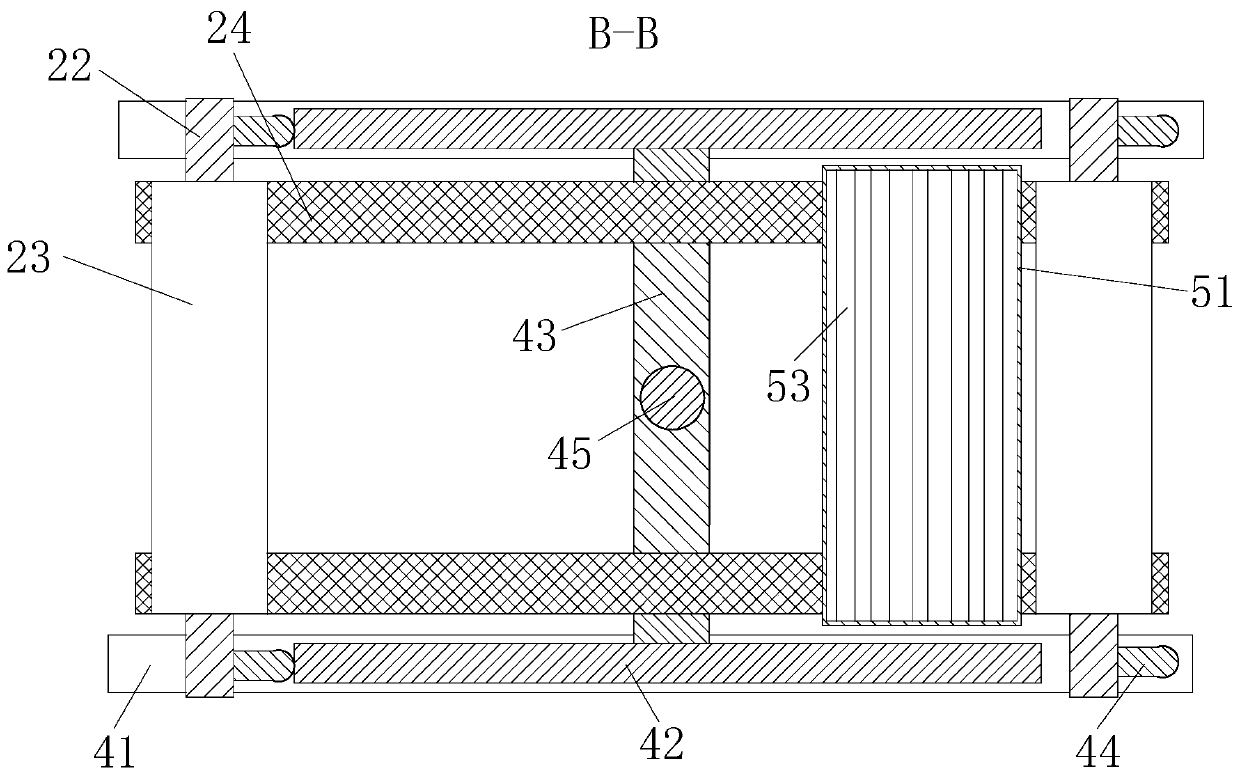

[0021] use Figure 1-Figure 4 A polyester textile fabric printing and dyeing equipment according to an embodiment of the present invention is described as follows.

[0022] Such as figure 1 , image 3 and Figure 4 As shown, a polyester textile fabric printing and dyeing equipment according to the present invention includes a printing and dyeing cylinder 1; a fabric conveying device 2 is arranged directly above the printing and dyeing cylinder 1, and a cloth is arranged at the upper port of the printing and dyeing cylinder 1 The transmission unit 3; the dye stirring unit 4 is arranged in the printing and dyeing cylinder 1, and the heating and drying unit 5 is arranged on one side of the printing and dyeing cylinder 1; wherein, the fabric conveying device 2 includes a first support rod 21, a rotating Column 22, first conveying roller 23, conveying belt 24, first magnet 25 and second magnet 26; the two sides of the printing and dyeing vat that described first support rod 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com