A Dual Gradient Drilling System Based on Coiled Tubing Electric Drive

An electric-driven, dual-gradient technology, applied in underwater drilling, earth-moving drilling, wellbore/well components, etc., can solve the problems of high cost of natural gas hydrate development, and achieve the effect of sustainable development and utilization and low construction risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

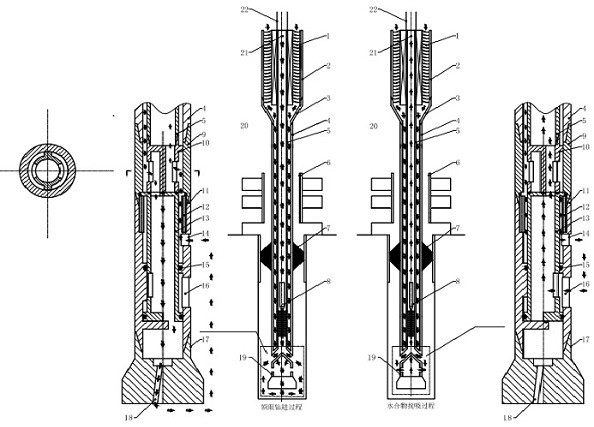

[0023] Such as figure 1 As shown, a dual-gradient drilling system based on coiled tubing electric drive includes a pilot drilling system and a hydrate stirring system; the pilot drilling system and hydrate stirring system include: coiled tubing 22, variable diameter Connector 3, cable 21, hollow electric multistage centrifugal pump 1, double-layer drill pipe 20, simple wellhead 6, casing blowout preventer 7, lift pump 8, outer casing 4, conversion joint 19, connecting casing 9, hollow Motor 12, drill bit 17, drill bit water eye 18; the coiled tubing 22 pulls the cable 21, and the cable 21 is connected to the hollow electric multistage centrifugal pump 1, thereby controlling the working power of the hollow electric multistage centrifugal pump 1; the hollow electric multistage centrifugal pump 1 is controlled; The electric multistage centrifugal pump 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com