Isolated microwave control type blanking tube valve

A controlled, cut-off tube technology, used in microwave heating, tube elements, tubes/pipe joints/fittings, etc., can solve problems such as liquid leakage, reduce loss, speed up expansion, and inhibit leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

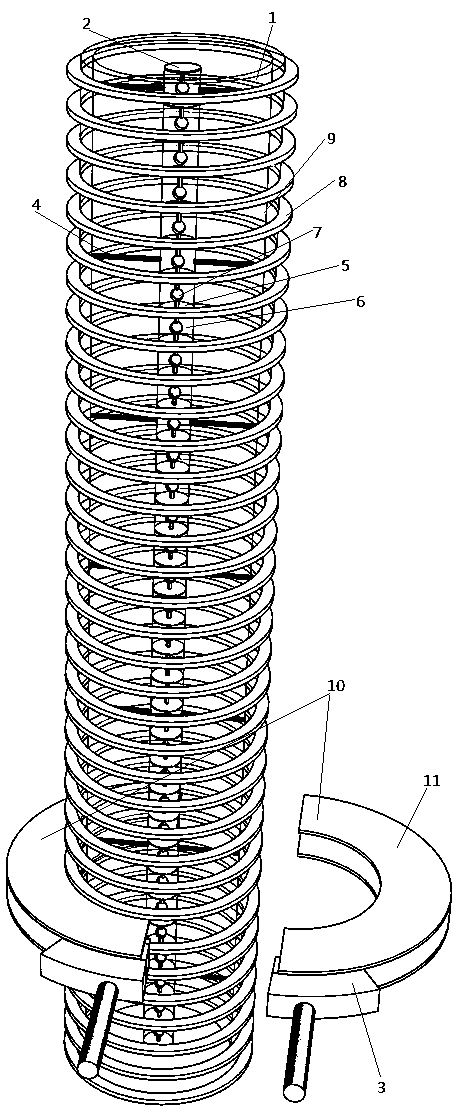

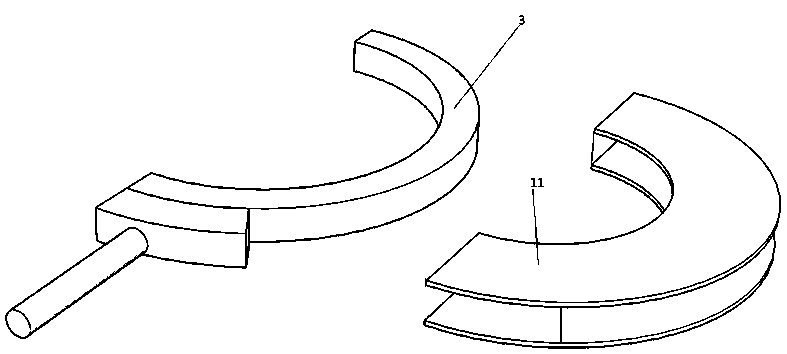

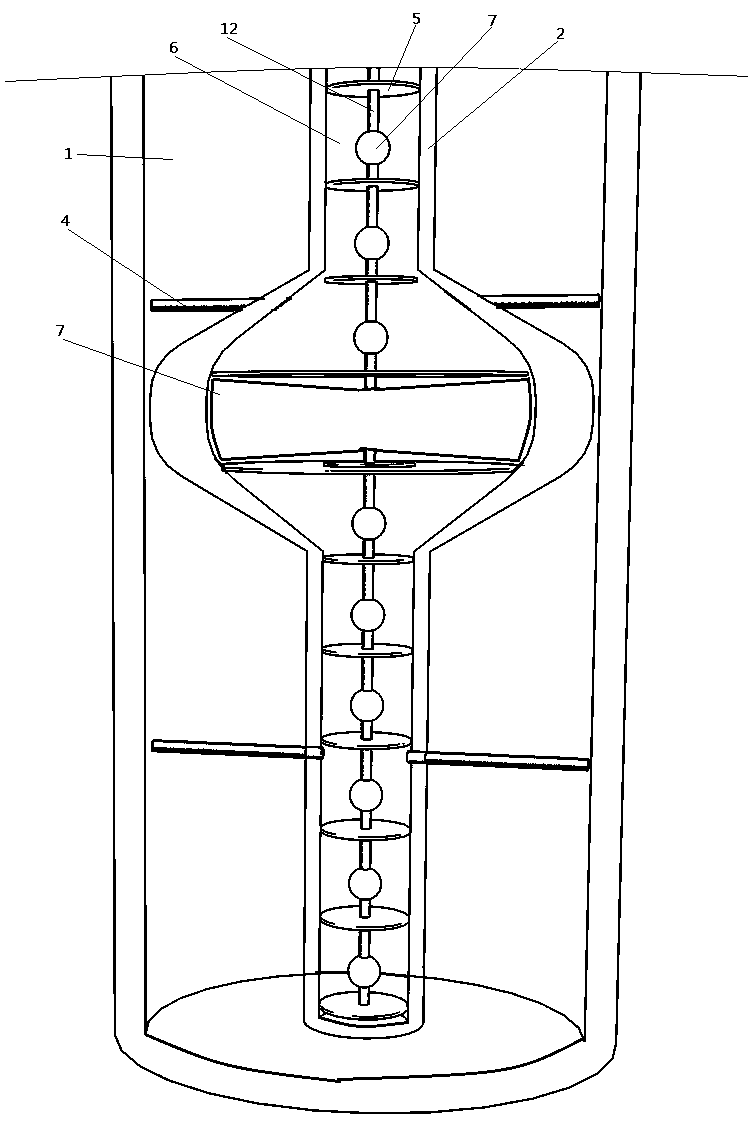

[0020] like Figure 1-4 As shown, the isolated microwave control type cut-off pipe valve includes a main pipe 1, an elastic inner core pipe 2, and two microwave heater modules 3; A limit rope 4; the limit rope 4 is all coated with waterproof paint; the inner surface of the elastic inner core tube 2 is evenly fixed and connected with several elastic partition plates 5 along the up and down direction; An expansion cavity 6; an elastic ball 7 with a cavity inside is placed in the expansion cavity 6; the inside of the elastic ball 7 is filled with ether; the outer surface of the main pipeline 1 is fixedly sleeved with several restricting rings 8; each upper and lower adjacent A limiting groove 9 is formed between the two limiting rings 8; the thickness of the limiting groove 9 is consistent with the thickness of the corresponding expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com