Industrial robot traction teaching system

A technology of industrial robots and mechanical arms, applied in the field of robots, can solve the problems of workers in danger, heavy objects falling, lack of power-off warning devices, etc., to achieve the effect of ensuring life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

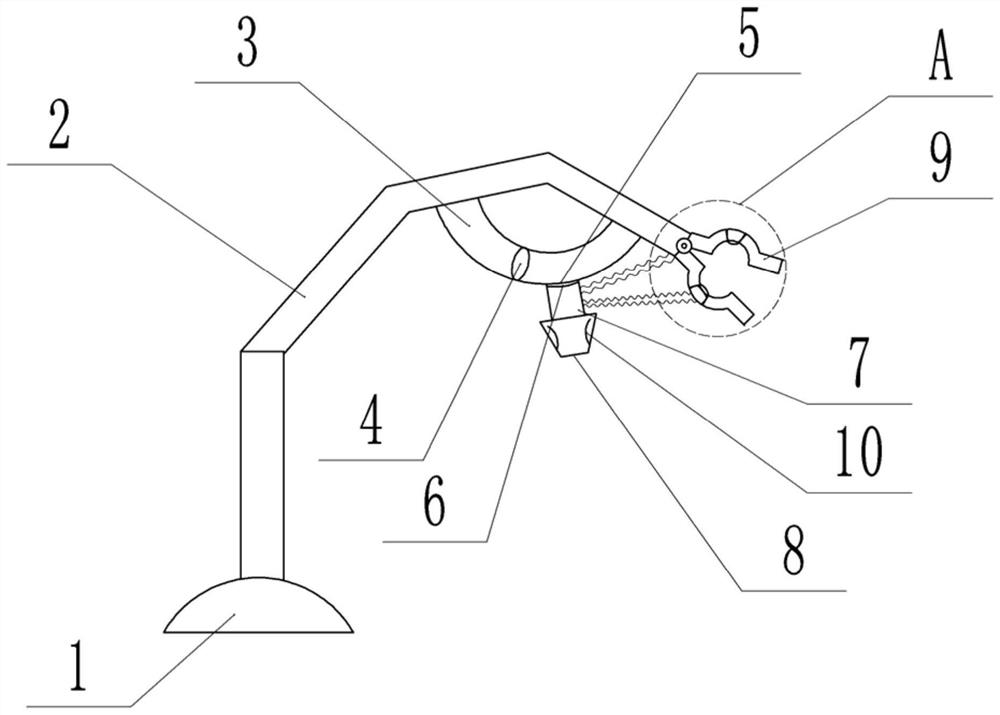

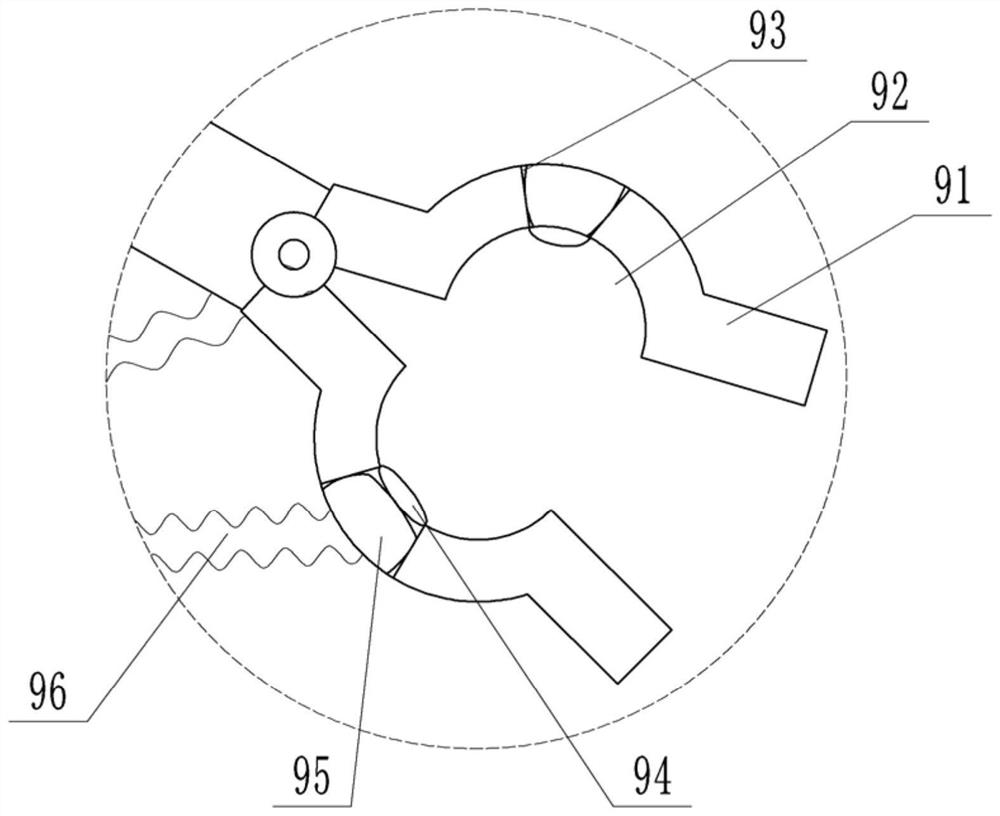

[0025] The reference signs in the accompanying drawings include: base 1, movable arm 2, U-shaped bag 3, solenoid valve 4, through hole 5, film 6, strip tube 7, conical casing 8, manipulator 9, reed 10. Clamping block 91, arc cavity 92, channel 93, suction cup 94, air bag 95, bellows 96.

[0026] Such as figure 1 As shown, the industrial robot traction teaching system of the present invention includes a multi-degree-of-freedom mechanical arm. The mechanical arm includes a base 1 and a plurality of movable arms 2. A movable joint is arranged between two adjacent movable arms 2. The movable arm 2 Connected to the base 1 sequentially through movable joints, a U-shaped bag 3 is arranged between two adjacent movable arms 2, and the two ends of the U-shaped bag 3 are fixedly connected with two adjacent movable arms 2 respectively, and the U-shaped bag 3 There is an electromagnetic valve 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com