Control method of energy system

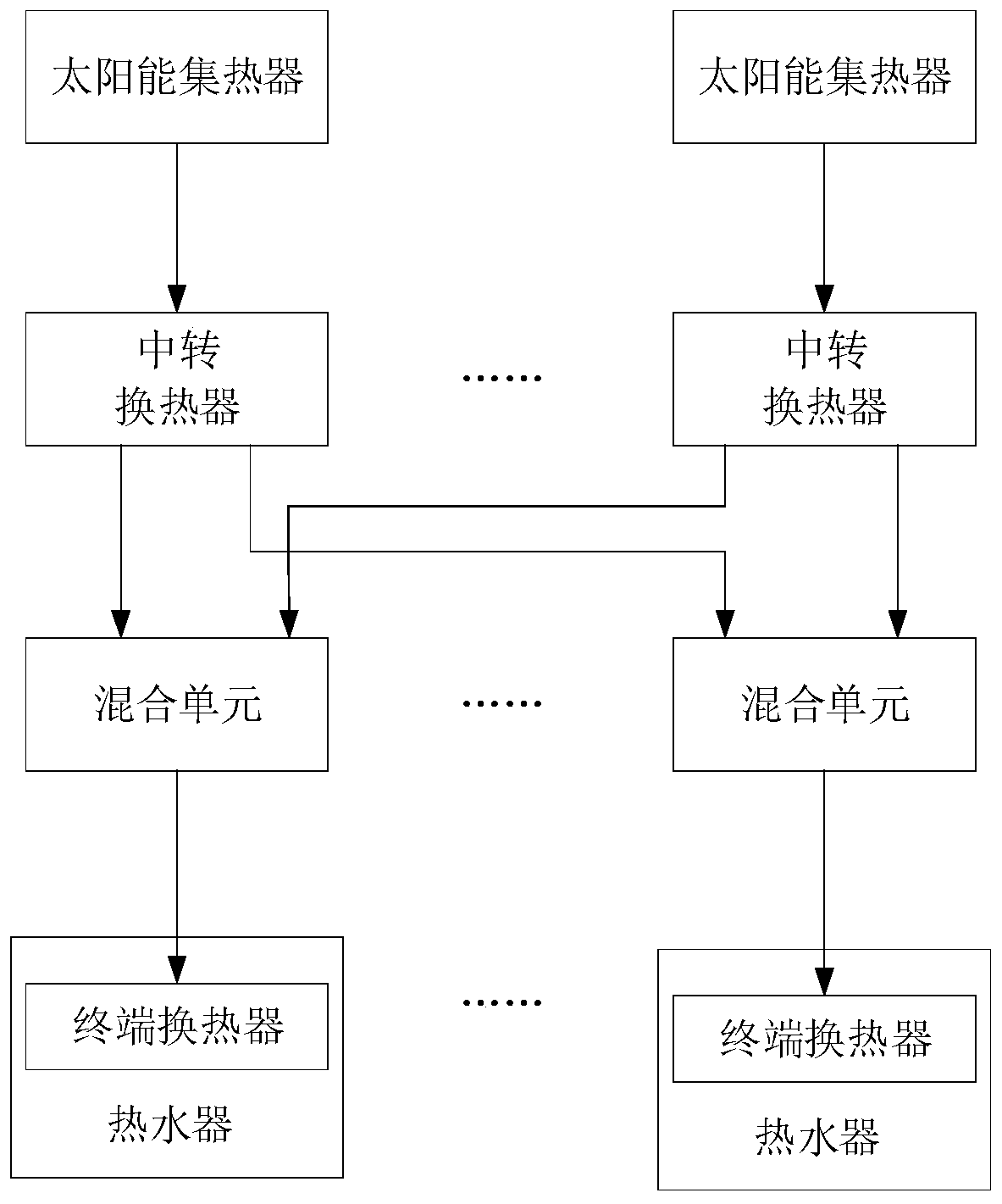

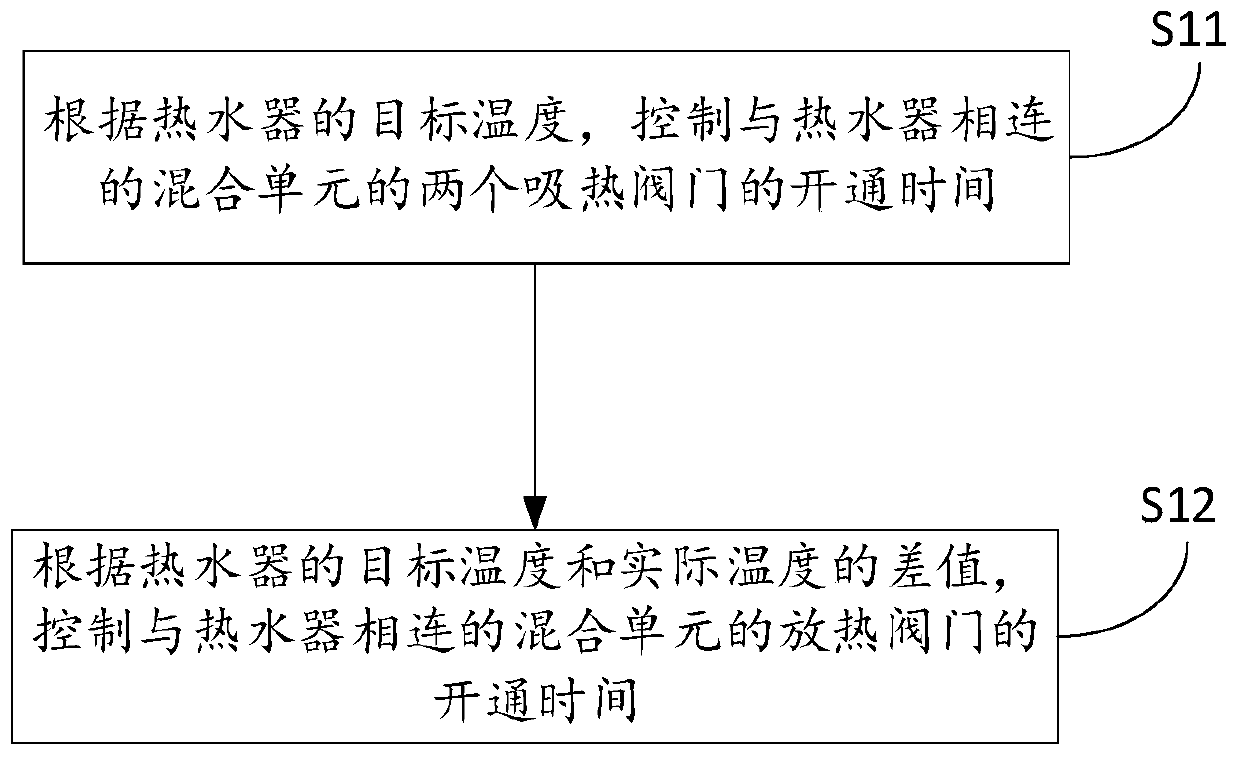

An energy system and control method technology, applied in solar heating systems, solar collector controllers, solar thermal energy and other directions, can solve the problems of inconvenient maintenance, inconvenience in daily life of the entire unit building, etc., and achieve the effect of reducing energy consumption and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

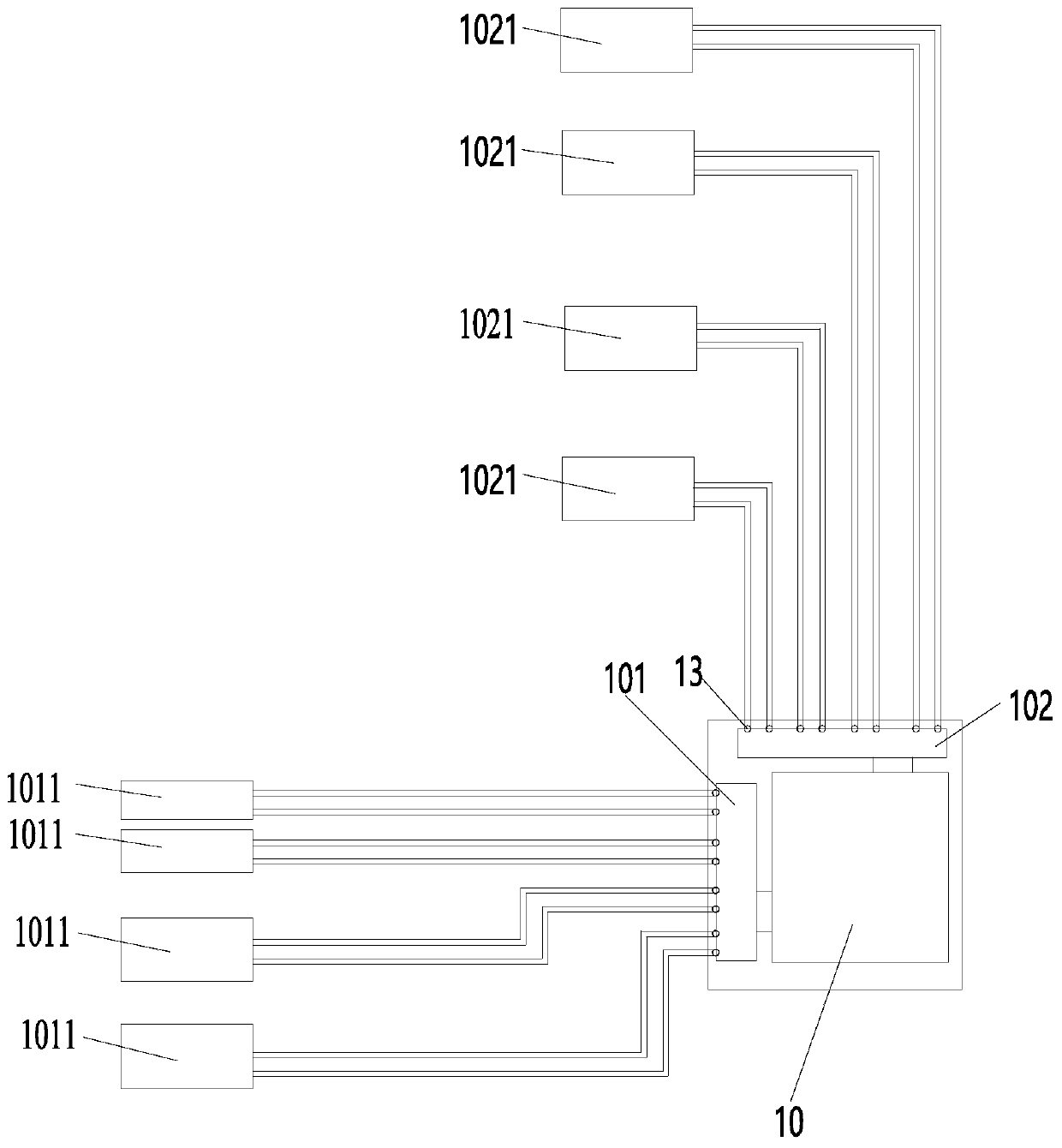

[0090]like Figure 3e As shown, in the first type of energy storage station 10, the energy absorbing end 101 is a first heat exchange device, which communicates with the heat exchange device on the side of the temperature adjustment equipment through a set of communication pipelines. The energy releasing end 102 is a second heat exchanging device, which communicates with the heat exchanging device on the side of the temperature adjustment equipment through a set of communication pipelines. That is, the pipelines at the energy absorbing end 101 and the pipelines at the energy releasing end 102 are set independently. That is, the energy absorbing end 101 of the first type of energy storage station 10 is a first heat exchange device with a set of independent communication pipelines, and the energy release end 102 is a second heat exchange device with a set of independent communication pipelines Group, used to communicate with the heat exchange device on the side of the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com