Flat copper wire motor stator assembly, manufacturing method thereof and motor using the same

The technology of a motor stator and its manufacturing method is applied to the flat copper wire motor stator assembly, its manufacturing method and the field of motors to which it is applied, which can solve the problems of wasting materials and low work efficiency, and achieve reduction of production cost, improvement of utilization rate, The effect of reducing the requirement of punching force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0030] It should be noted that all expressions using "first" and "second" in the embodiments of the present invention are to distinguish two entities with the same name but different parameters or parameters that are not the same, see "first" and "second" It is only for the convenience of expression, and should not be construed as a limitation on the embodiments of the present invention, which will not be described one by one in the subsequent embodiments.

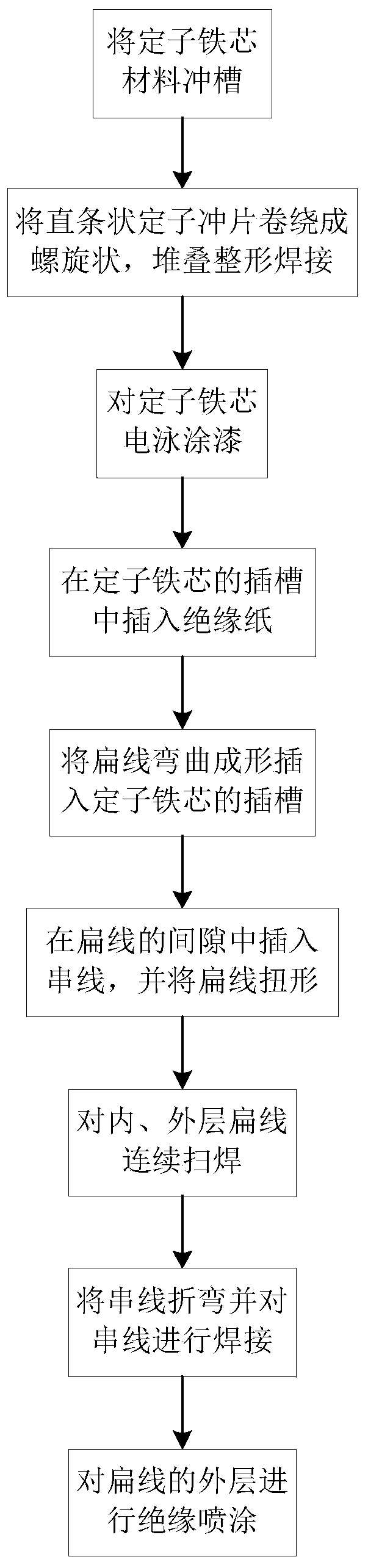

[0031] A method for manufacturing a flat copper wire motor stator assembly, comprising the following steps:

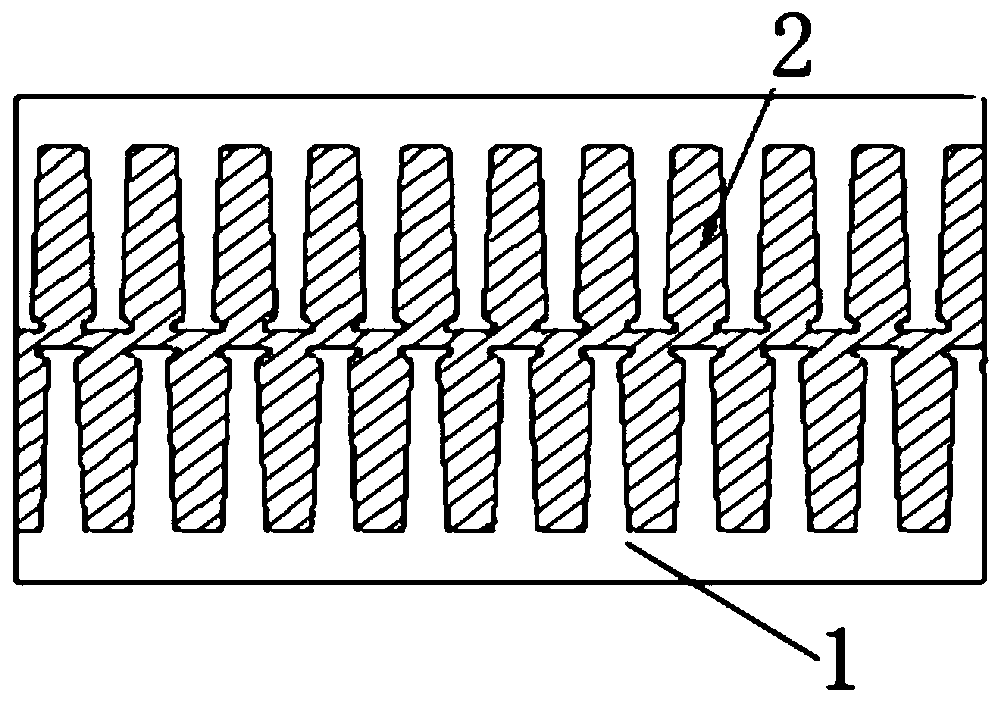

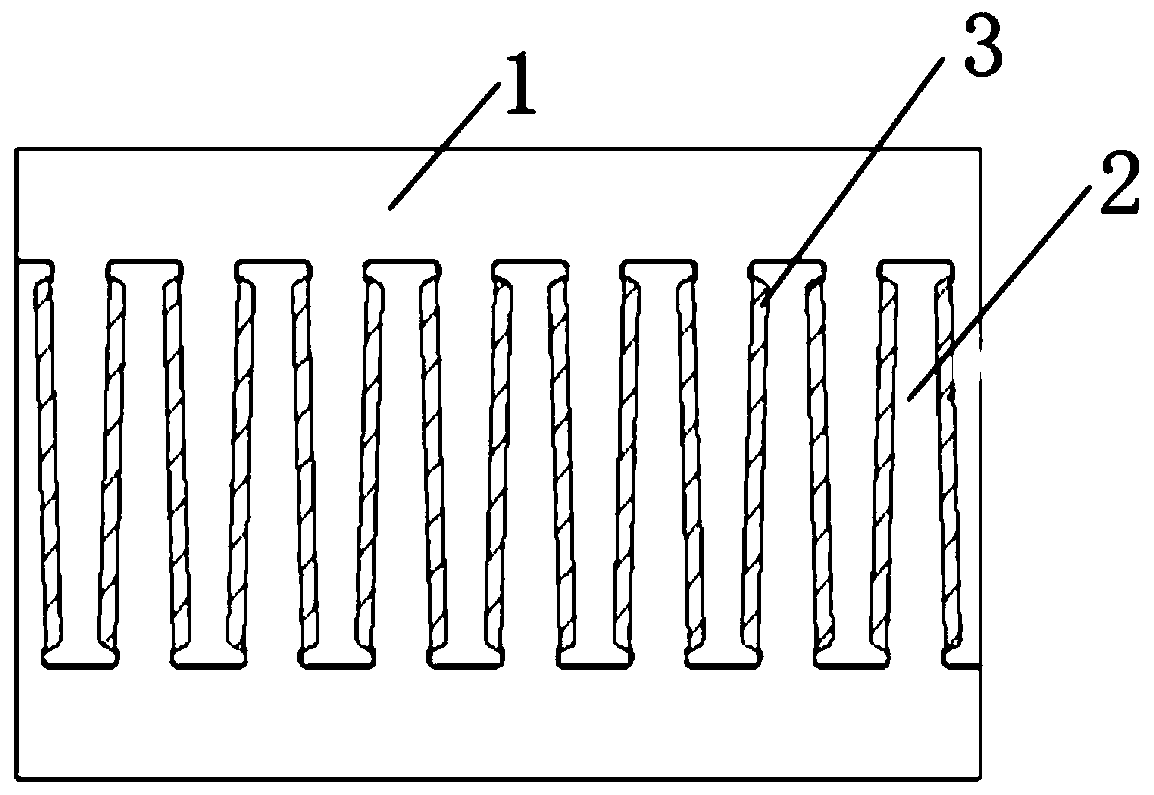

[0032] a. Groove the stator core material to obtain a straight stator sheet with multiple grooves. Optionally, select a silicon steel sheet with a thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com