Cleaning tool for squeezing flat mop

A flat mop and cleaning tool technology, applied in the field of squeezing flat mop cleaning tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0130] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

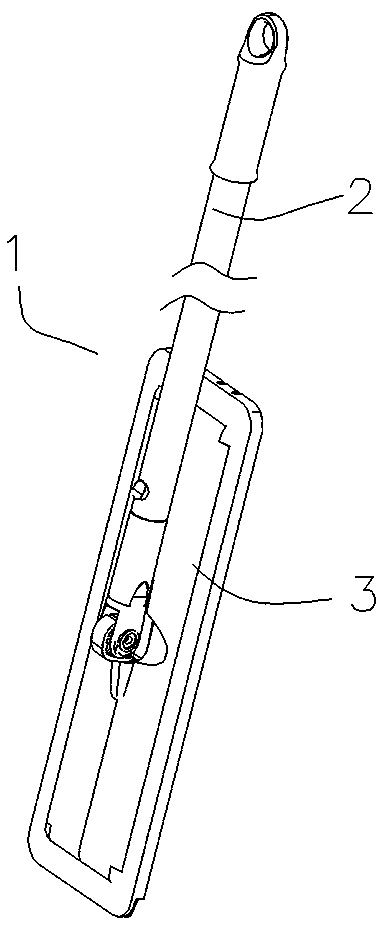

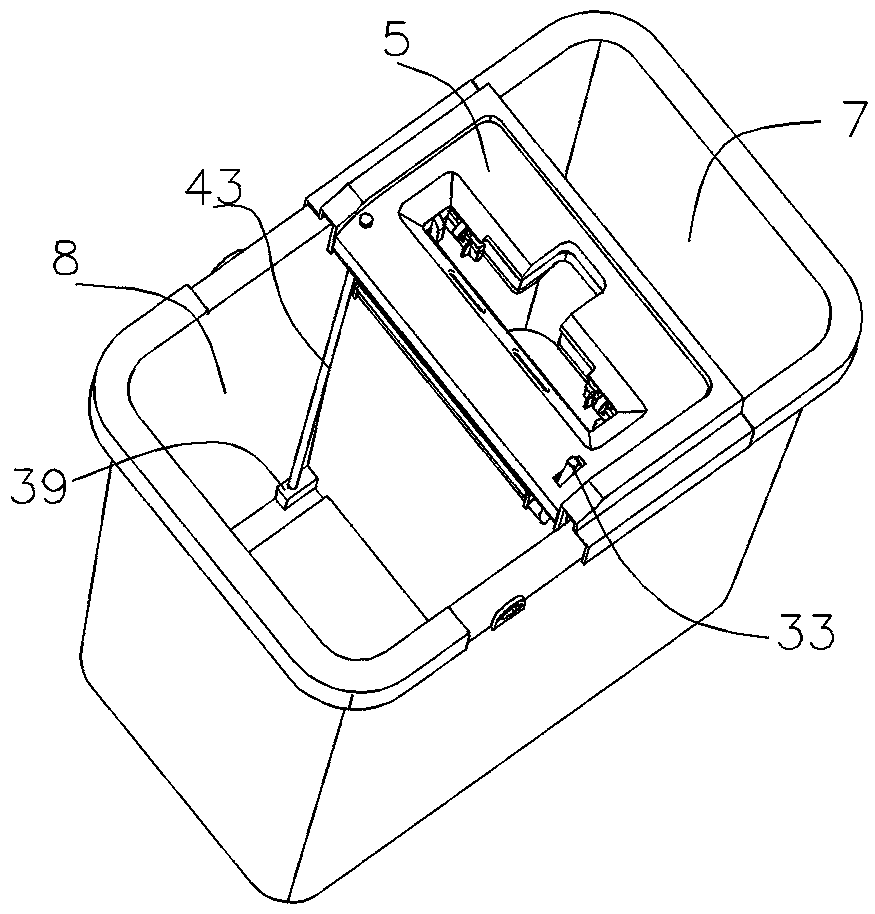

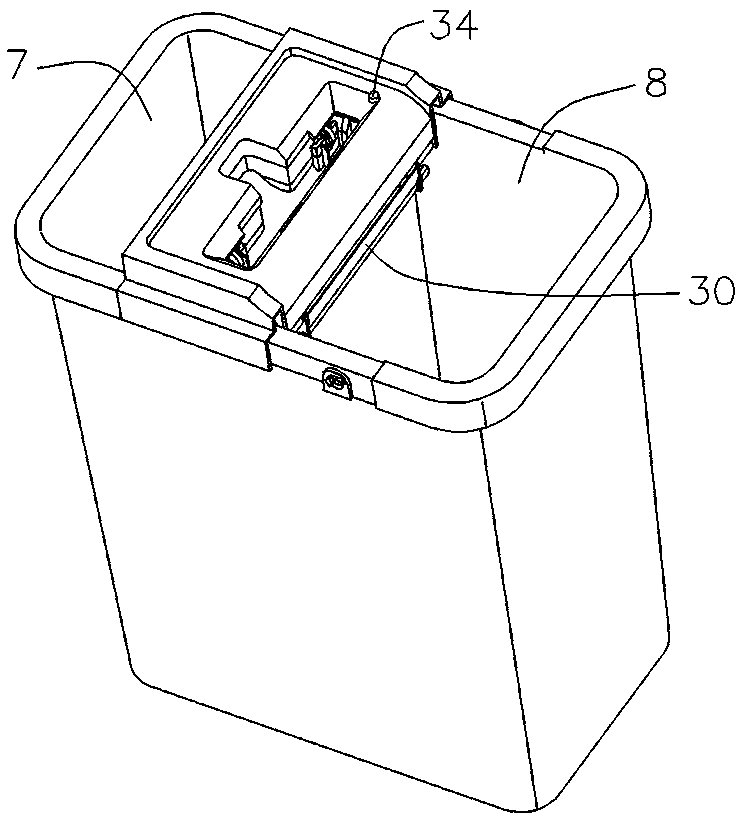

[0131] refer to Figure 1-Figure 69 , extruding a flat mop cleaning tool, comprising a mop bucket and a flat mop 1, the flat mop 1 comprising a mop rod 2 and a hard flat mop head 3 flexibly connected to the mop rod 2, the flat mop A wiper 4 is arranged on the head 3, and the wiper 4 is usually arranged on the back side of the flat mop head 3. The movable connection mode between the flat mop head 3 and the mop bar 2 is prior art, and will not be repeated here.

[0132] Described mop barrel is provided with extruding frame 5, offers opening on described extruding frame 5, is provided with extruder on the extruding frame of described opening side, and the other side of described extruder and opening An extrusion port 6 is formed between one side, and the extruder can be movably connected to the extrusion frame, or can be fixed on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com