A continuous forging press

A press and forging technology, applied in the field of continuous forging presses, can solve the problems of affecting the process, affecting the quality of the plate, and poor versatility, so as to reduce labor intensity and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

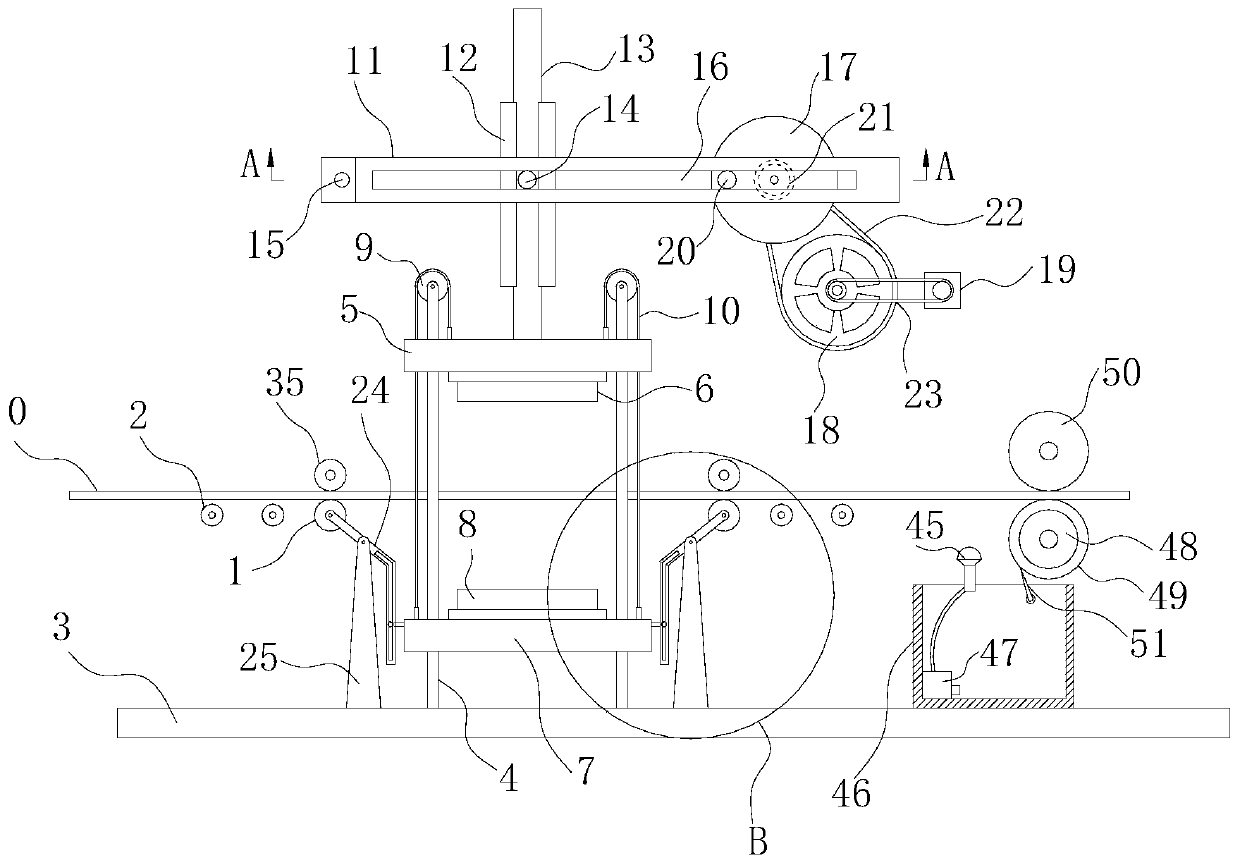

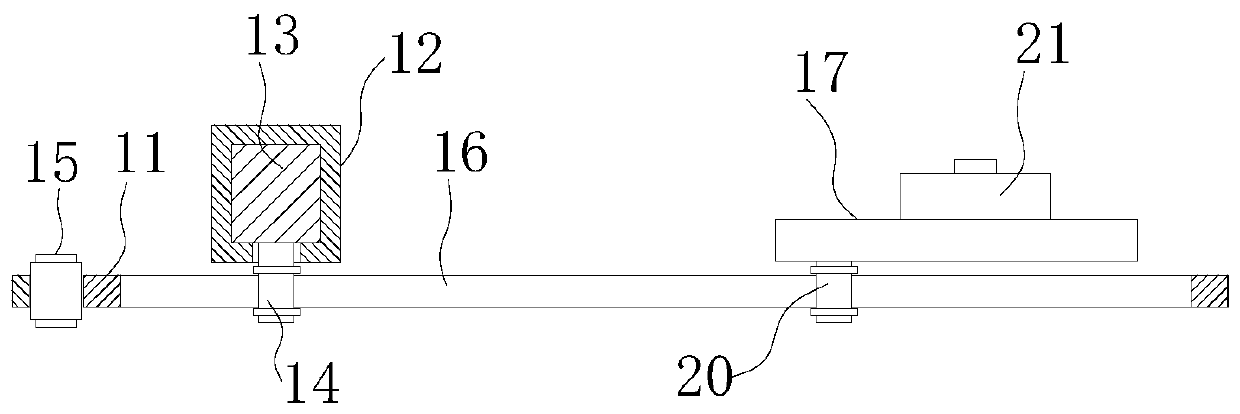

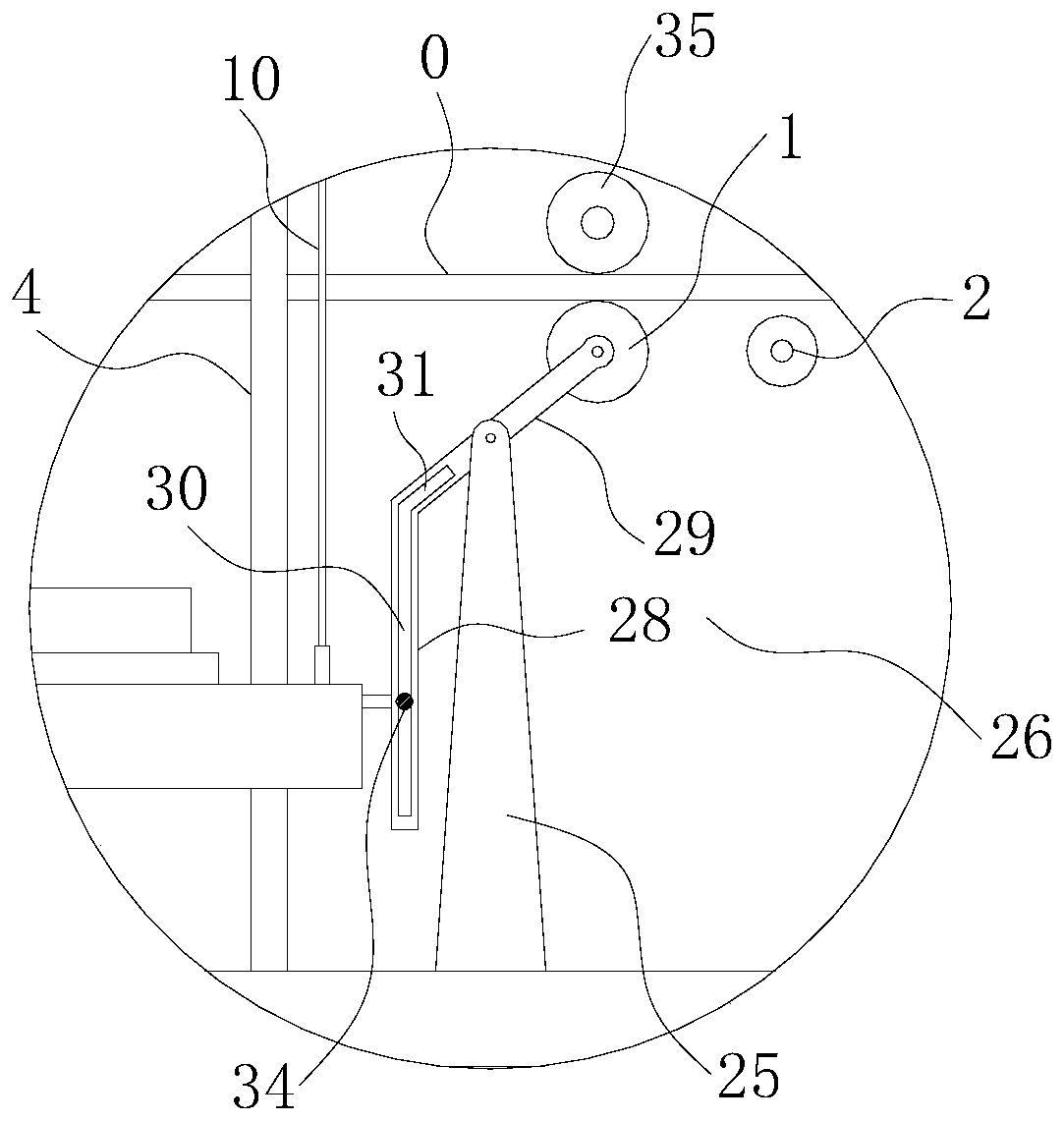

[0029] combine Figure 1-7 The continuous forging press shown includes a conveying device for conveying sheet metal and a forging device for forging sheet metal. The forging device can perform intermittent forging on the plate, and the conveying device combines the forging frequency of the forging device to transport the plate section by section to the bottom of the forging device. In essence, that is to say, when the press according to the present invention is working, when the forging device forges the plate, the conveying device stops conveying. During a period of time when the forging device is lifted, the conveying device conveys the sheet material.

[0030] Such as figure 1 As shown, the conveying device of the present invention includes two active conveying rollers 1 arranged on the feed side and the discharge side of the forging device, and the active conveying roller 1 is a conveying roller that can be actively rotated under the drive of the conveying motor , to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com