3000-ton oil press punching method

A hydraulic press and punching technology, which is applied in the direction of piercing tools, forming tools, feeding devices, etc., can solve problems such as low centering accuracy, low centering efficiency of forgings, and delay in forging punching continuity of hydraulic presses, etc., to achieve high efficiency High, high centering precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

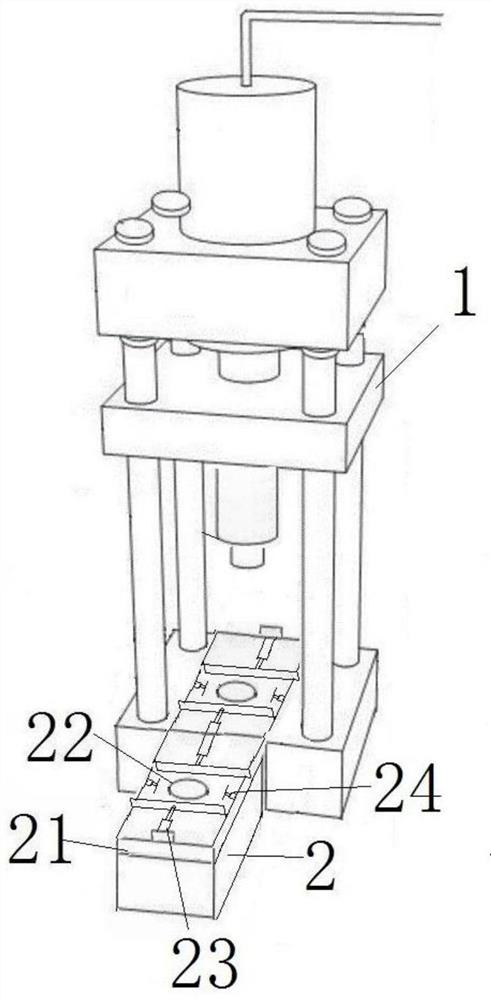

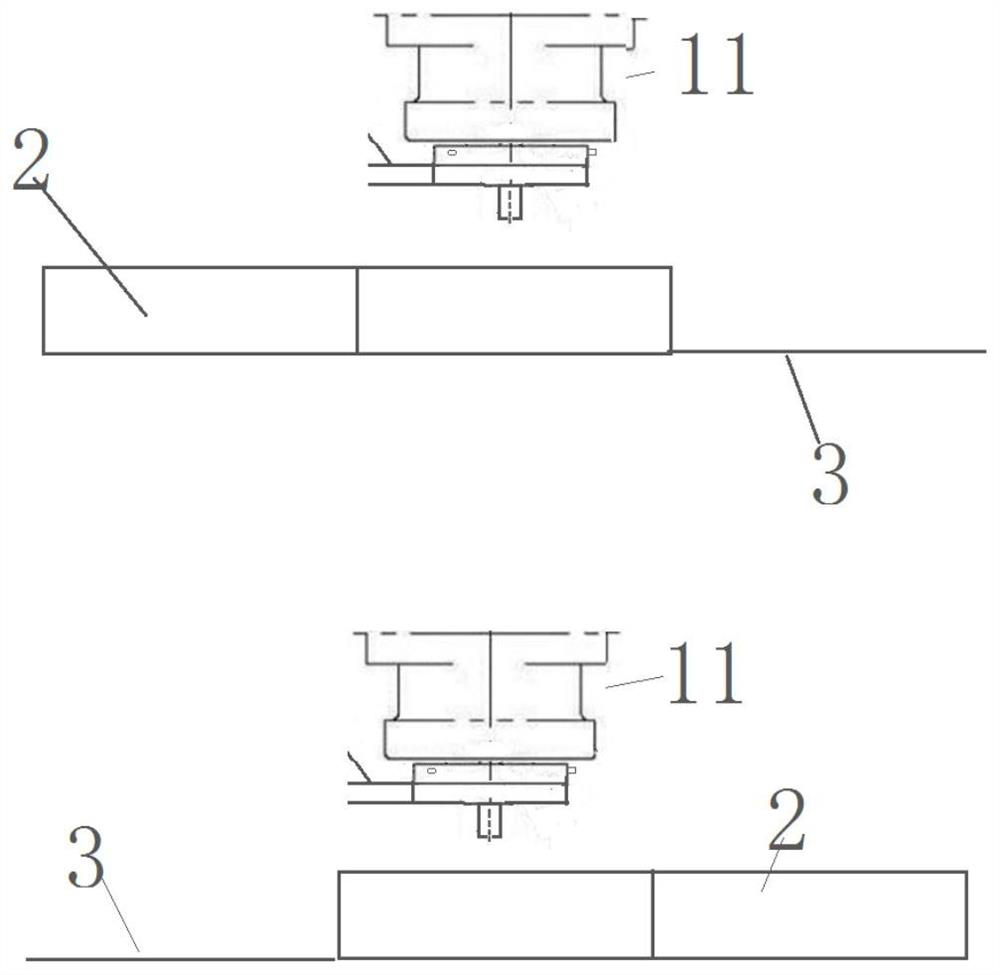

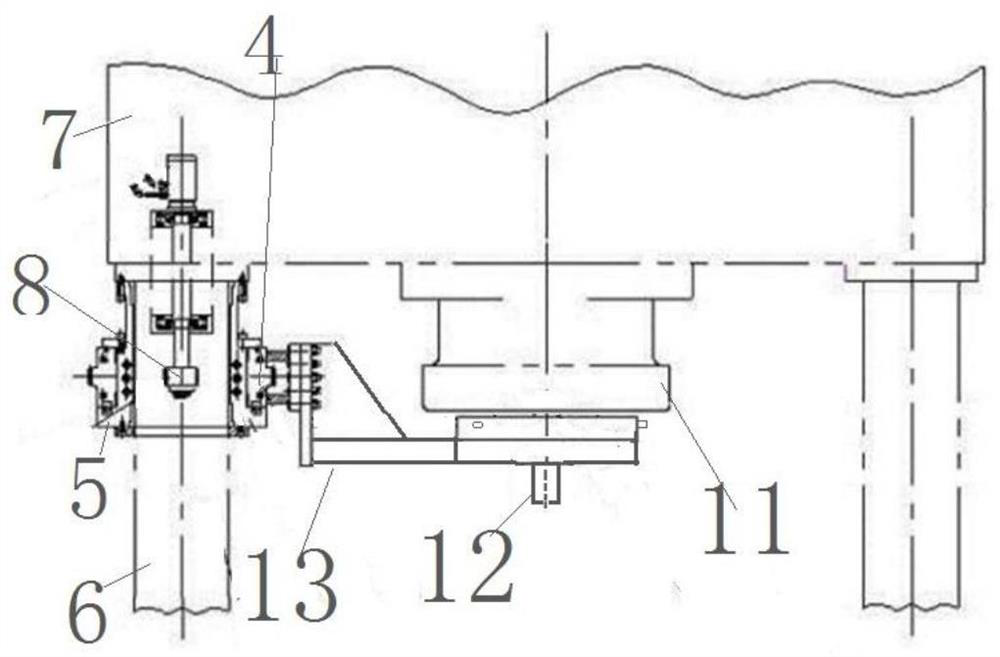

[0028] Attached below Figure 1-5 The invention is further described as figure 1 , a 3,000-ton hydraulic press, a slide rail 3 is provided under the hydraulic column 11 of the hydraulic press 1, and the slide rail 3 extends a certain distance to the left and right sides; a workbench 2 is slidably connected to the top of the slide rail 3, and the workbench 2 includes two punches Hole station, when the workbench 2 slides back and forth above the slide rail 3, the two punch stations are located directly below the hydraulic cylinder 11 in turn; each punch station includes a load-bearing platform 21, a support rod, and a pair of horizontal alignment A device 23 and a pair of longitudinal centering devices 24, and a through hole 1 22 is opened in the center of the load-bearing platform 21 .

[0029] Such as figure 2 As shown, the slide rail 3 is a lead screw slide rail, and one end of the lead screw slide rail is connected to a servo motor drive device. Through the servo motor d...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that both the horizontal centering device 23 and the longitudinal centering device 24 are cylinders with displacement sensors.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is that both the horizontal centering device 23 and the longitudinal centering device 24 are electric telescopic rods with displacement sensors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com