Negative pressure drainage type casting and forging forming device and method for metal material

A negative pressure drainage, metal material technology, applied in the field of metal material preparation and processing, can solve the problems of easily causing gas entrainment, slag entrainment, low product performance, melt entrainment, etc., to improve production efficiency, reduce gas content, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

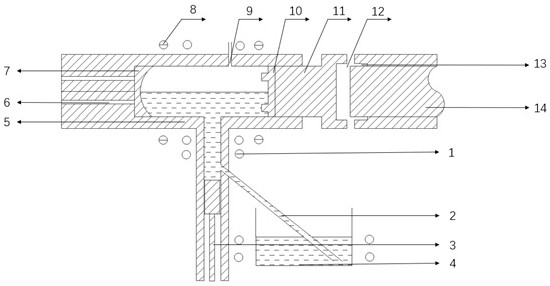

[0033] Negative pressure drainage casting and forging of 4032 aluminum alloy.

[0034] The 4032 aluminum alloy is melted in the melting furnace 4, the liquid lifting device 2 is inserted into the metal melt, the negative pressure device is turned on, a certain negative pressure value is set, and the negative pressure treatment is performed on the inside of the mold cavity 5 to make The mold cavity 5 is in a negative pressure state. At this time, the 4032 aluminum alloy solution with a temperature of 560~580°C slowly enters the mold cavity 5 through the feeding device 2 due to the negative pressure. When the melt rises to a certain height, the feeding is stopped and the negative pressure pumping device 9 is closed. Adjust the electromagnetic heater 1 to control the temperature of the cavity at about 530 ℃, push the high-pressure extrusion piston 3 to perform high-pressure reverse extrusion casting, the extrusion pressure is 300 MPa, the pressure for maintaining pressure is 300 ...

Embodiment 2

[0036] Negative pressure drainage casting and forging of A356 aluminum alloy.

[0037]Melt the A356 aluminum alloy in the melting furnace 4, insert the liquid lifting device 2 into the metal melt, turn on the negative pressure device, set a certain negative pressure value, and perform negative pressure pumping treatment on the inside of the cavity 5 to make the mold The chamber 5 is in a negative pressure state. At this time, the A356 aluminum alloy solution with a temperature of 690°C slowly enters the mold cavity 5 through the liquid generating device 2 due to the negative pressure. When the melt rises to a certain height, the feeding is stopped and the negative pressure pumping device 9 is closed. Adjust the electromagnetic heater 1 to control the temperature of the cavity at about 690°C, push the high-pressure extrusion piston 4 for high-pressure reverse extrusion casting, the extrusion pressure is 300 MPa, the pressure holding pressure is 300 MPa, and the pressure is main...

Embodiment 3

[0039] Negative pressure drainage casting and forging of 7075 aluminum alloy.

[0040] Melt the 7075 aluminum alloy in the melting furnace 4, insert the liquid lifting device 2 into the metal melt, turn on the negative pressure device, set a certain negative pressure value, and perform negative pressure pumping treatment on the inside of the cavity (5), Make the cavity 5 in a negative pressure state. At this time, the 7075 aluminum alloy solution with a temperature of 650~690°C slowly enters the cavity 5 through the feeding device 2 due to the negative pressure. When the melt rises to a certain height, the feeding is stopped and the negative pressure pumping device 9 is closed. Adjust the electromagnetic heater 1 to control the temperature of the cavity at about 630°C, push the high-pressure extrusion piston 4 to perform high-pressure reverse extrusion casting, the extrusion pressure is 300 MPa, the pressure holding pressure is 300 MPa, and the pressure is maintained. 60s; pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com