Mechanical hand flexible fixture finger based on magnetorheological fluid

A magnetorheological fluid, manipulator technology, applied in manipulators, chucks, manufacturing tools, etc., can solve the problems of poor adaptability and inability to adjust the clamping stiffness, and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

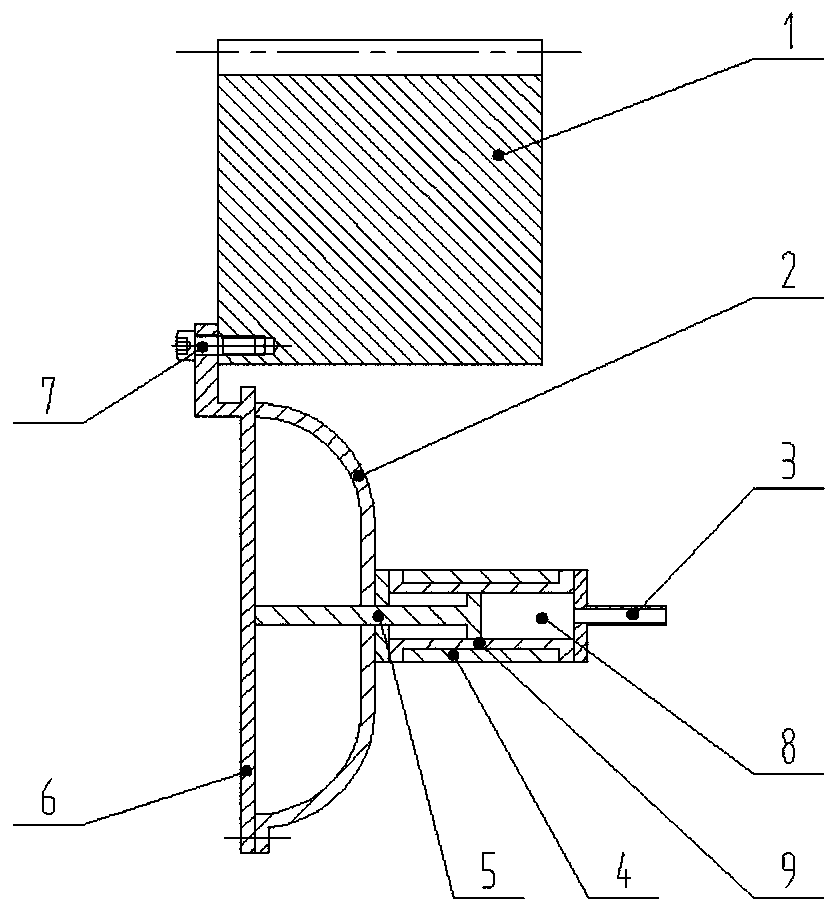

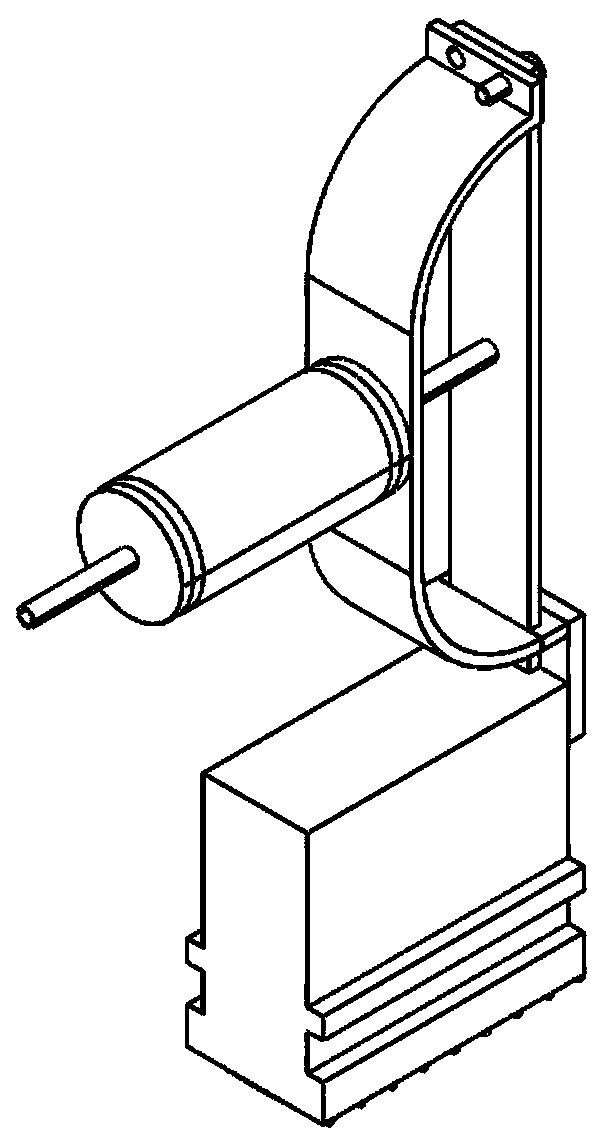

[0019] refer to Figure 1 to Figure 4 , a manipulator compliant gripper finger based on magneto-rheological fluid, the guide block 1 is fixedly connected to the upper end of the arc-shaped member 2 by a screw 7, the spring leaf 6 is fixedly connected to the lower end of the arc-shaped member 2 by bolts, and the upper end penetrates and It can slide within a certain range, and the upper end surface of the guide block 1 has convex ribs, which can be engaged with the spiral groove in the chute of the palm body of the pliable fixture. During the clamping operation, the guide block can move centripetally or centrifugally in the chute.

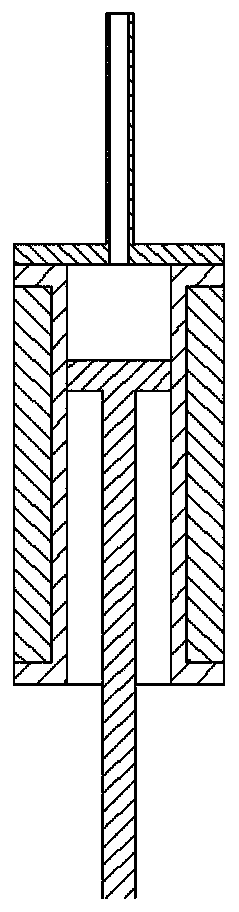

[0020] The conduit 3, the electromagnetic coil 4, the piston rod 5, the magnetorheological fluid 8, and the sleeve 9 together form a compliant clamp finger damper, the electromagnetic coil 4 is arranged outside the sleeve 9, and the conduit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com