Tetraphenylethylene macrocyclic compound with mechanofluorescent color-changing performance, synthesis method and use

A technology of macrocyclic compounds and tetraphenylethylene, applied in chemical instruments and methods, organic chemistry, color-changing fluorescent materials, etc., can solve problems such as non-luminescence, limited applications, and weakened fluorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

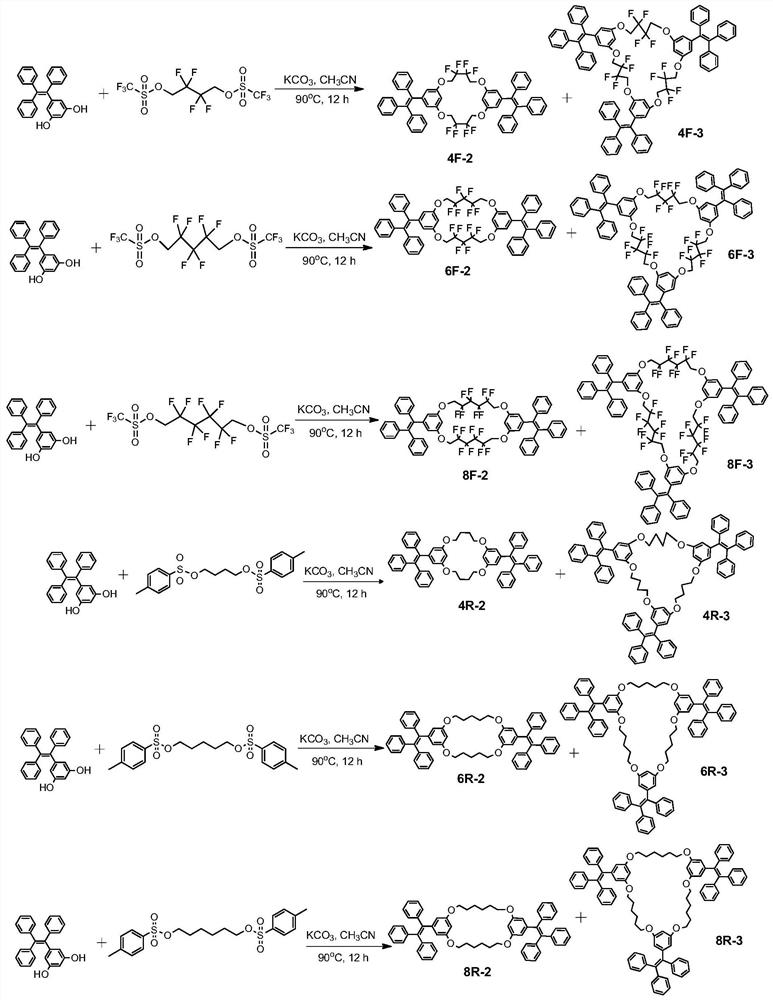

Method used

Image

Examples

Embodiment 1

[0047] In a 250 mL round bottom flask, 2-bromo-1,1,2-triphenylethylene (3.3524 g, 10 mmol), 3,5-dimethoxyphenylboronic acid (2.731 g, 15 mmol), tetra-n-butyl bromide Ammonium (0.3224g, 1mmol), potassium carbonate (4.976g, 36mmol, first dissolved in 18mL water) and Pd (PPh 3 ) 4 (0,01g, 0.001mmol) dissolved in 60mL toluene, airtight, N 2 Gas was washed three times, and the mixture was stirred and refluxed for 12 hours at 95°C. DCM was added for dilution, the organic layer was washed with water and saturated brine respectively, and the organic layer was dried over anhydrous sodium sulfate. Column chromatography with petroleum ether:ethyl acetate (V:V=20:1) gave a white solid as shown in Formula 11, namely TPE-OMe, with a yield of 98.7%.

[0048] NMR spectrum of TPE-OMe: 1 H NMR (600MHz, CDCl3) δ7.20–7.00(m, 15H), 6.25(d, J=1.8Hz, 1H), 6.21(d, J=1.8Hz, 2H), 3.56(s, 6H). 13 C NMR (151MHz, CDCl 3 )δ=159.95,145.52,143.91,143.57,143.24,141.07,140.90,131.31,131.25,130.96,127.76,...

Embodiment 2

[0051] Add TPE-OMe (3.9218g, 10mmol) to 150mL DCM in 300mL, then add 3.6mL boron tribromide (BBr 3 ) was slowly dropped into it, and after the drop was completed, the temperature was raised to room temperature, and stirred for 12h. DCM was added for dilution, the organic layer was washed with water and saturated brine respectively, and the organic layer was dried over anhydrous sodium sulfate. Column chromatography with petroleum ether:ethyl acetate (V:V=5:1) gave a white solid as shown in Formula 12, namely TPE-OH, with a yield of 100.0%.

[0052] NMR spectrum of TPE-OH: 1 H NMR (600MHz, DMSO) δ9.00(s, 2H), 6.93-7.12(m, 15H), 5.96(s, 1H), 5.89(d, J=1.3Hz, 2H). 13 C NMR (151MHz, CDCl 3 )δ157.97, 148.13, 145.49, 145.41, 145.20, 143.16, 142.01, 133.26, 133.16, 133.02, 129.72, 129.66, 129.62, 128.67, 128.49, 113.14, 103.30. HRMS: C 26 h 20 o 2 for [M]+, calculated 364.1463, found 364.1464.

[0053]

Embodiment 3

[0055] 2,2,3,3-tetrafluoro-1,4-butanediol (4.0000 g, 24.68 mmol), 2,2,3,3,4,4-hexafluoro-1, 5-pentanediol (5.2386g, 24.68mmol) or 2,2,3,3,4,4,5,5-octafluoro-1,6-hexanediol (6.4667g, 24.68mmol) was added to 75mL DCM Cool to 0°C, add 5 mL of pyridine, stir for 10 minutes, then slowly drop trifluoromethanesulfonic anhydride (12.5 mL, 74.04 mmol) into it, warm to room temperature after dropping, and stir for 12 h. DCM was added to dilute, washed with water and saturated brine respectively, then dried with anhydrous sodium sulfate, and spin-dried to obtain white solid 4F-OTf, oil 6F-OTf and white solid 8F-OTf, respectively, with a yield of 100.0%.

[0056] NMR spectrum of compound 4F-OTf: 1 H NMR (600MHz, CDCl 3 )δ5.06–4.60(m,4H). 19 F NMR (565MHz, CDCl3) δ -74.06, -120.47.

[0057] The nuclear magnetic spectrum of compound 6F-OTf: 1 H NMR (600MHz, DMSO) δ5.50 (s, 4H). 19 F NMR (565MHz, DMSO) δ-75.14, -119.75, -124.26.

[0058] The NMR spectrum of compound 8F-OTf: 1 H NMR (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com