Pull rope fastening device for inner suspension holding pole during assembly of power transmission tower

A technology for a transmission tower and a fastening device is applied in the field of a pull-rope fastening device for suspending a pole within the transmission tower assembly, which can solve the problems of destroying the galvanized layer of the tower material, time-consuming and laborious, and potential safety hazards, saving manpower and safety. time, ensure reliability, and increase the effect of safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

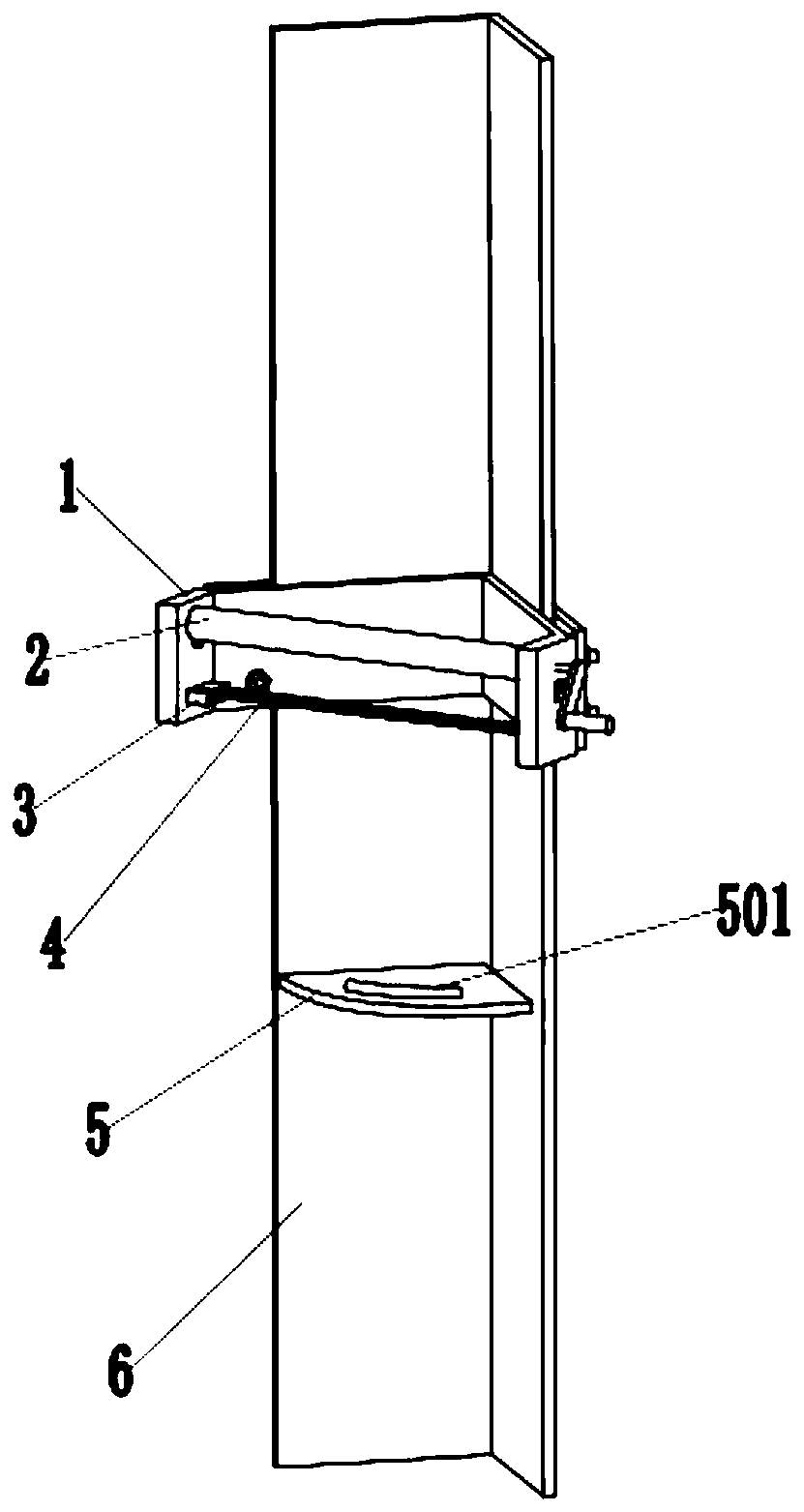

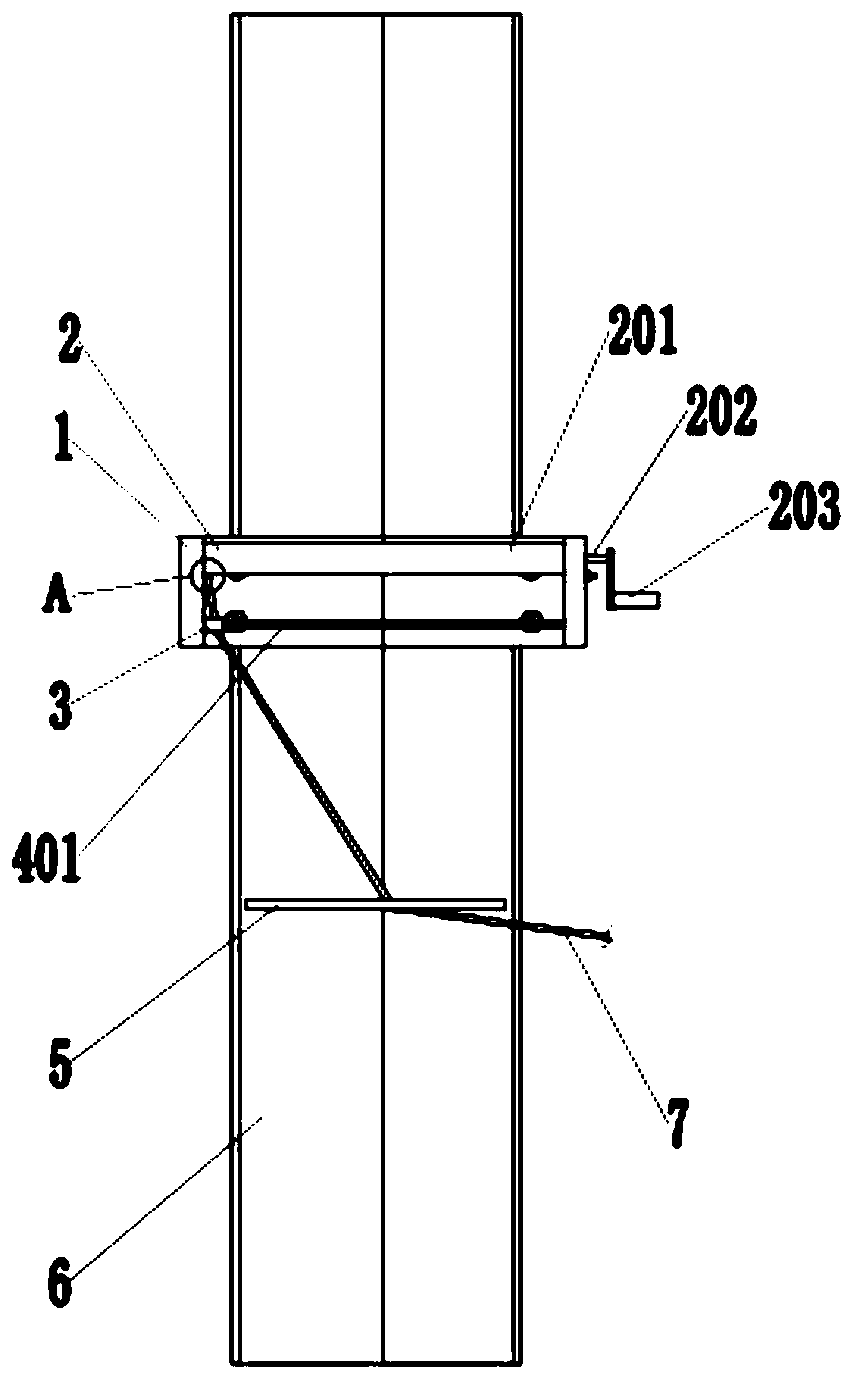

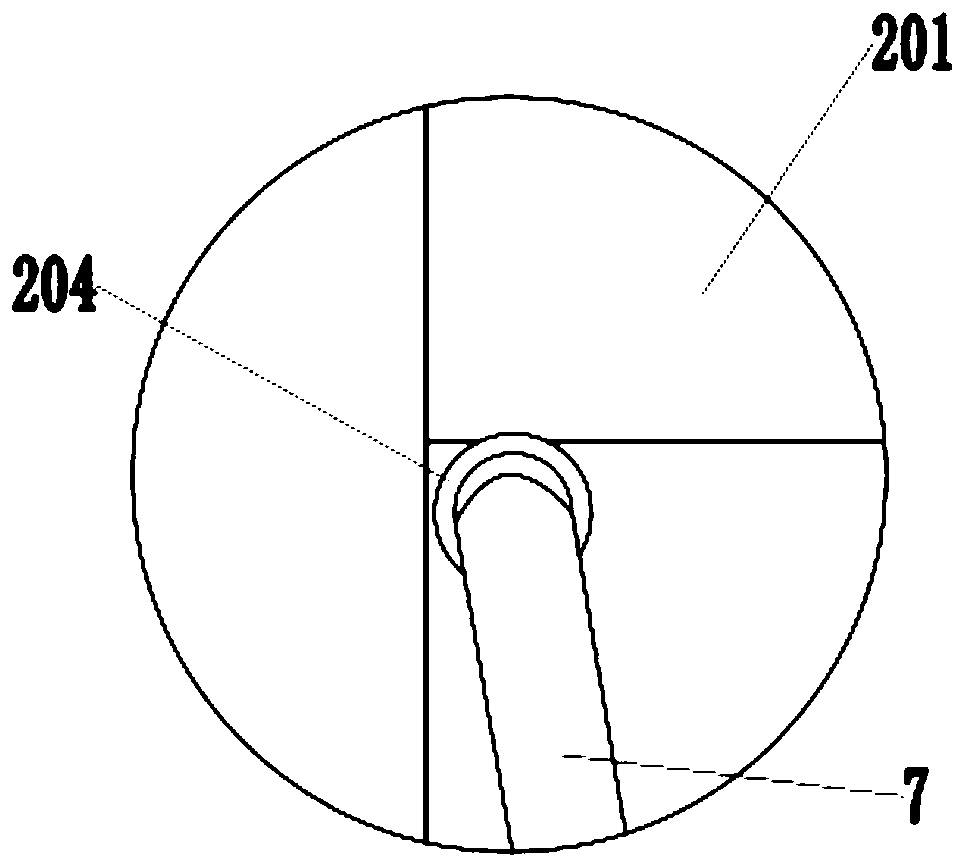

[0035] Such as figure 1 , 2 As shown in , 4, a stay rope fastening device for suspending the pole when the transmission iron tower is erected includes a clamping device 1 and a rope winding device 2, and the clamping device 1 includes an outer angle steel plate 101 and an inner angle steel plate 102. The end of the outer angle steel plate 101 and the end of the inner angle steel plate 102 are connected by bolts. One end of the inner angle steel plate 102 is provided with a first connection box 103, and the other end of the inner angle steel plate 102 is provided with a second connection box 104. The device 2 includes a rope winding drum 201, a rotating shaft 202, and a handle 203. The rope winding drum 201 is set on the outside of the rotating shaft 202. The rope winding drum 201 is arranged between the first connection box 103 and the second connection box 104. The rotating shaft 202 One end of the connecting box 103 is connected to the first connecting box 103, and the hand...

Embodiment 2

[0040] In order to ensure that the stay rope 7 can be evenly wound on the rope winding drum 201, to prevent local winding only, or the stay rope 7 is inclined to cause inconvenient winding.

[0041] Such as figure 1 , 2 As shown, a guide rail 4 is provided below the rope winding drum 201, and the guide rail 4 is connected to the rotating shaft 202, and a wire slider 3 is provided on the guide rail 4. Through the wire slider 3, the stay rope can be evenly wound on the rope winding drum 201, preventing excessive local winding of the rope, saving space, making the rope winding drum 201 more evenly stressed, and improving the bearing capacity.

[0042] Such as figure 2 , 4 As shown, the guide rail 4 includes a lead screw 401 and a slide bar 402, and the slide bar 402 is arranged in parallel with the lead screw 401, as Figure 7 As shown, the first connection box 103 is provided with driving teeth 106, driving teeth 107, and driven teeth 108, and the two ends of the sliding ro...

Embodiment 3

[0047] In order to prevent the wire slider 3 from being damaged at a certain angle between the stay rope 7 and the wire slider 3 during the rope winding process, it is not conducive to rope winding.

[0048] Such as figure 1 As shown, in order to solve the above problems, a guide plate 5 is also provided in this embodiment, the guide plate 5 is arranged under the guide rail 4, the guide plate 5 is welded to the main material 6 of the tower leg, and the guide plate 4 is provided with Guide hole 501.

[0049] The edge of the guide hole 501 is rounded, and the guide hole 501 is an arc hole. On the one hand, the guide plate 5 plays the role of reinforcing the main material 6 of the tower leg. On the other hand, the guide plate 5 is provided with an arc-shaped guide hole 501. The guide hole 501 can guide the stay rope 7 to prevent the stay rope 7 from shifting. , to prevent the wire slider 3 from being directly pulled by the pull rope 7 to prevent damage to the wire slider 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com