Coal mine goaf grouting hole grout-stopping process under deep burying condition of strong confined aquifer

A technology for confined aquifers and goafs, which is applied to mining equipment, earthwork drilling, fillings, etc., can solve problems that affect underground safety production and affect the quality of filling and grouting in goafs, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

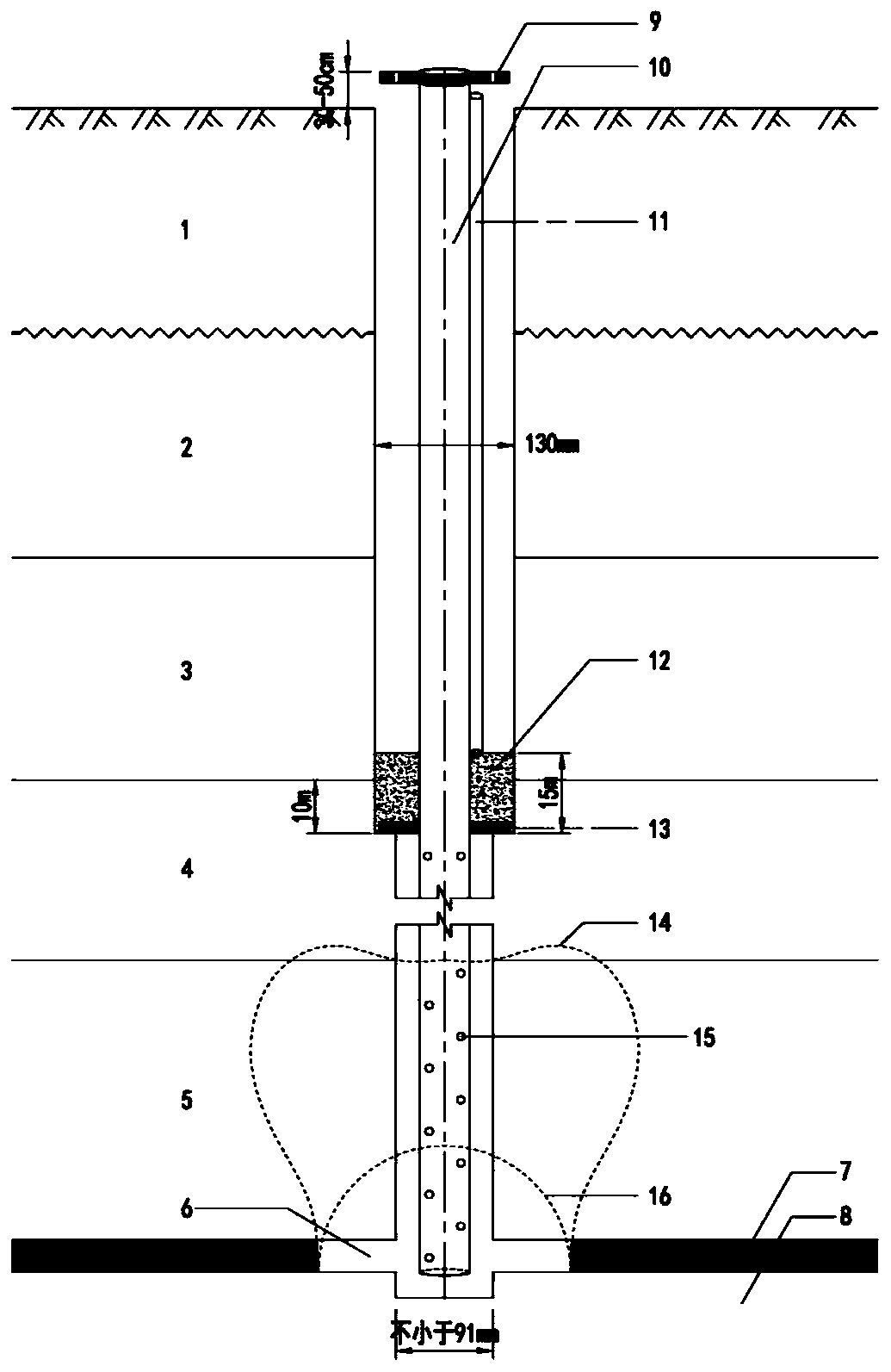

[0030] The goaf management project in a reservoir area, the goaf is formed by fully mechanized mining, mining 4 -2 One layer of coal, the roof management method is free caving, the average buried depth of the gob is 510m, the thickness of the coal seam is 7.1m, and there is a permeable layer of the lower Cretaceous Luohe Formation in the overlying bedrock of the gob. Grouting drilling is divided into two types: full-hole coring pilot drilling and general grouting hole. The "one-time hole forming, bottom-up, intermittent full filling" process is adopted, and the specific implementation steps are as follows:

[0031] (1) Drilling construction: it includes four steps of hole position measurement, drilling rig installation, drilling into holes, and pouring grouting pipes;

[0032] ① Hole position measurement: Grouting drilling should use measuring instruments such as RTK or total station to carry out point-by-point field stakeout according to the engineering design hole position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com