Resin emulsion plugging agent composition, preparation method thereof and application of composition in fractured stratum

A technology of resin emulsion and plugging agent, which is used in drilling compositions, chemical instruments and methods, and earthwork drilling and mining, etc., can solve the problems of poor long-term temperature resistance and high temperature resistance in high temperature resistance, and achieve low construction costs. , Improve the strength, the effect of less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0080] This preparation example is to illustrate the water-based resin emulsion prepared by the present invention.

[0081] (1) Tween80 and 1g of hydrophilic nano-SiO with a mass fraction of 10g 2 At the same time, add it to 39mL deionized water, stir well to make it dissolve evenly, and obtain a solution;

[0082] (2) Add 50 g of resin binder urea-formaldehyde resin to the solution prepared in step (1), and stir at a high speed under the stirring condition of 600 rpm to make it emulsify evenly.

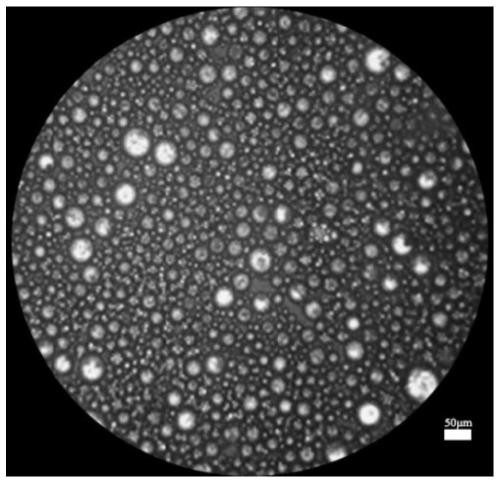

[0083] As a result, a water-based resin emulsion 1 was obtained. The performance parameters were as follows: the water-based resin emulsion was an oil-in-water emulsion with a viscosity of 35 mPa.s. The particles in the dispersed phase were regular spherical particles with an average particle diameter of 635 nm.

[0084] figure 1 It is the micrograph observed under a microscope of the water-based resin emulsion 1 prepared by Preparation Example 1 of the present invention; figure 1...

preparation example 2

[0086] This preparation example is to illustrate the water-based resin emulsion prepared by the present invention.

[0087] (1) Tween80 with a mass fraction of 6g and hydrophilic nano-SiO of 2g 2 At the same time, add it to 62mL deionized water, stir well to make it dissolve evenly, and obtain a solution;

[0088] (2) Add 30 g of resin binder amino resin into the solution prepared in step (1), stir at high speed to make it emulsify evenly.

[0089] As a result, water-based resin emulsion 2 was obtained. The performance parameters were as follows: the water-based resin emulsion was an oil-in-water emulsion with a viscosity of 25 mPa.s, and the particles in the dispersed phase were regular spherical particles with an average particle diameter of 850 nm.

Embodiment 1

[0091] This embodiment is to illustrate the resin emulsion plugging agent prepared by the method of the present invention.

[0092] The composition of the resin emulsion plugging agent is: the water-based resin emulsion 1 prepared in Preparation Example 1; the curing agent is modified diethylenetriamine; the coupling agent is γ-aminopropyltriethoxysilane; nano hectorite It is a nanoscale lamellar lithium bentonite with positive charge on the crystal surface and negative charge on the edge of the crystal. It is disc-shaped with an average diameter of 25nm and an average thickness of 0.92nm; the flexible fiber is polypropylene fiber with an average diameter of 60μm , with an average length of 1mm and a density of 0.91g / cm 3 .

[0093] The content of the resin emulsion plugging agent is: the consumption of the water-based resin emulsion 1 is 93.1wt%, the consumption of the curing agent is 4wt%, the consumption of the coupling agent is 0.4wt%, the nanometer lithium soap The amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com