Idler wheel rocking arm

A technology of rollers and rocker arms, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increased production costs, complex manufacturing processes, high requirements for component processing and assembly, and achieve simplified manufacturing processes and reduced components. The effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

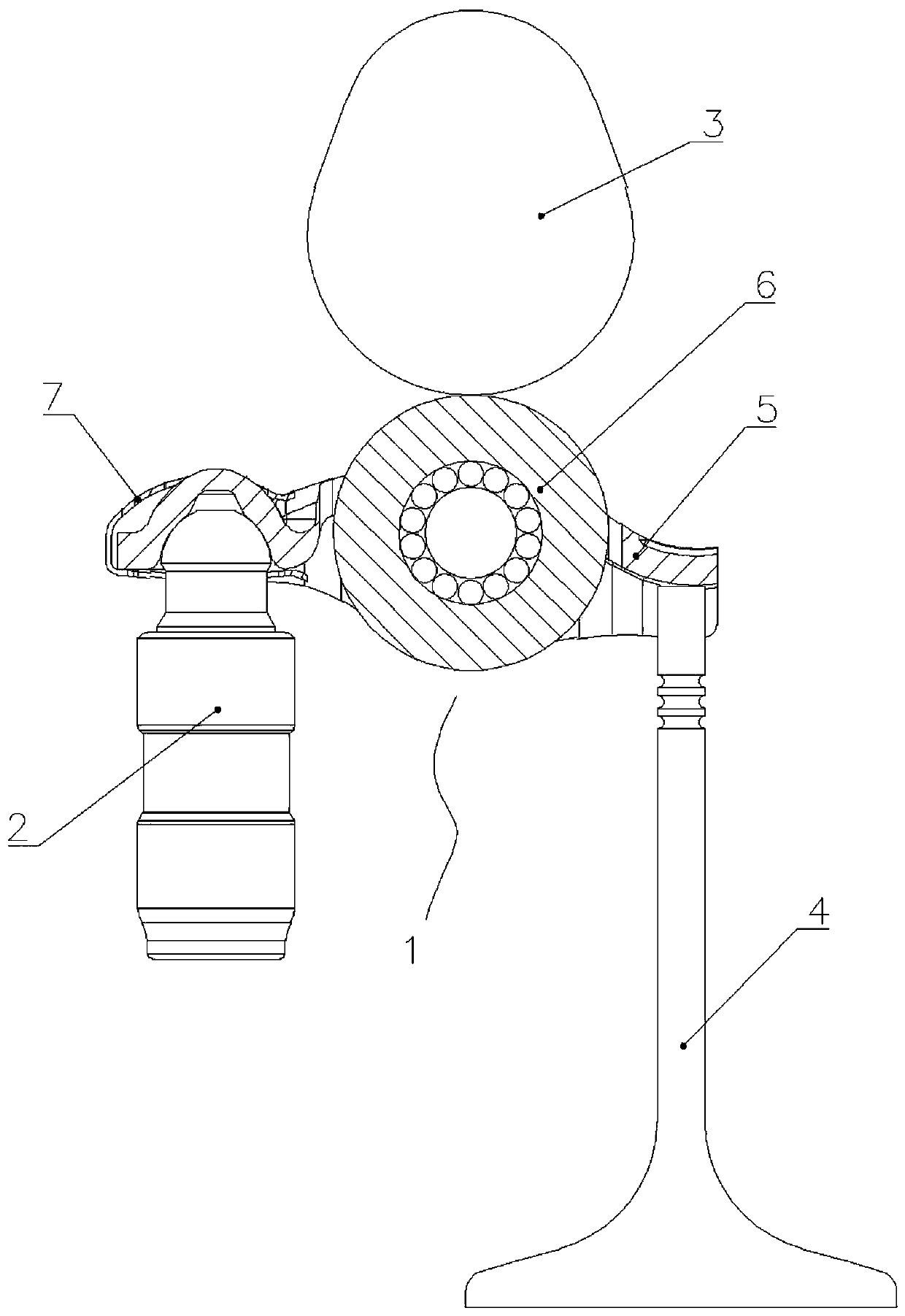

[0048] Embodiment one: if Figure 1-6 As shown, the roller rocker arm, the rocker arm mechanism 1 is installed between the tappet 2, the cam 3 and the valve 4, including the rocker arm frame 5 and the roller kit 6, the rocker arm frame 5 includes side walls 5.1, 5.2 and has a bearing surface 5.5, the bottom plate of the ball socket 5.6, there is an assembly hole 5.7 between the bearing surface 5.5 and the ball socket 5.6, pin holes 5.3, 5.4 are opened on the side walls 5.1, 5.2 located at the assembly hole 5.7, and the roller set 6 includes a pin shaft 6.1 , the roller outer ring 6.2 and the needle roller 6.3, the ball head of the tappet 2 is connected with the ball socket 5.6 through the ball card 7, the valve 4 slides against the bearing surface 5.5, and the roller assembly 6 is assembled in the pin hole 5.3 through the pin shaft 6.1, The assembly hole 5.7 between 5.4, the cam 3 rolls against the roller outer ring 6.2, through the rocker arm mechanism 1, the cam 3 transmits ...

Embodiment 2

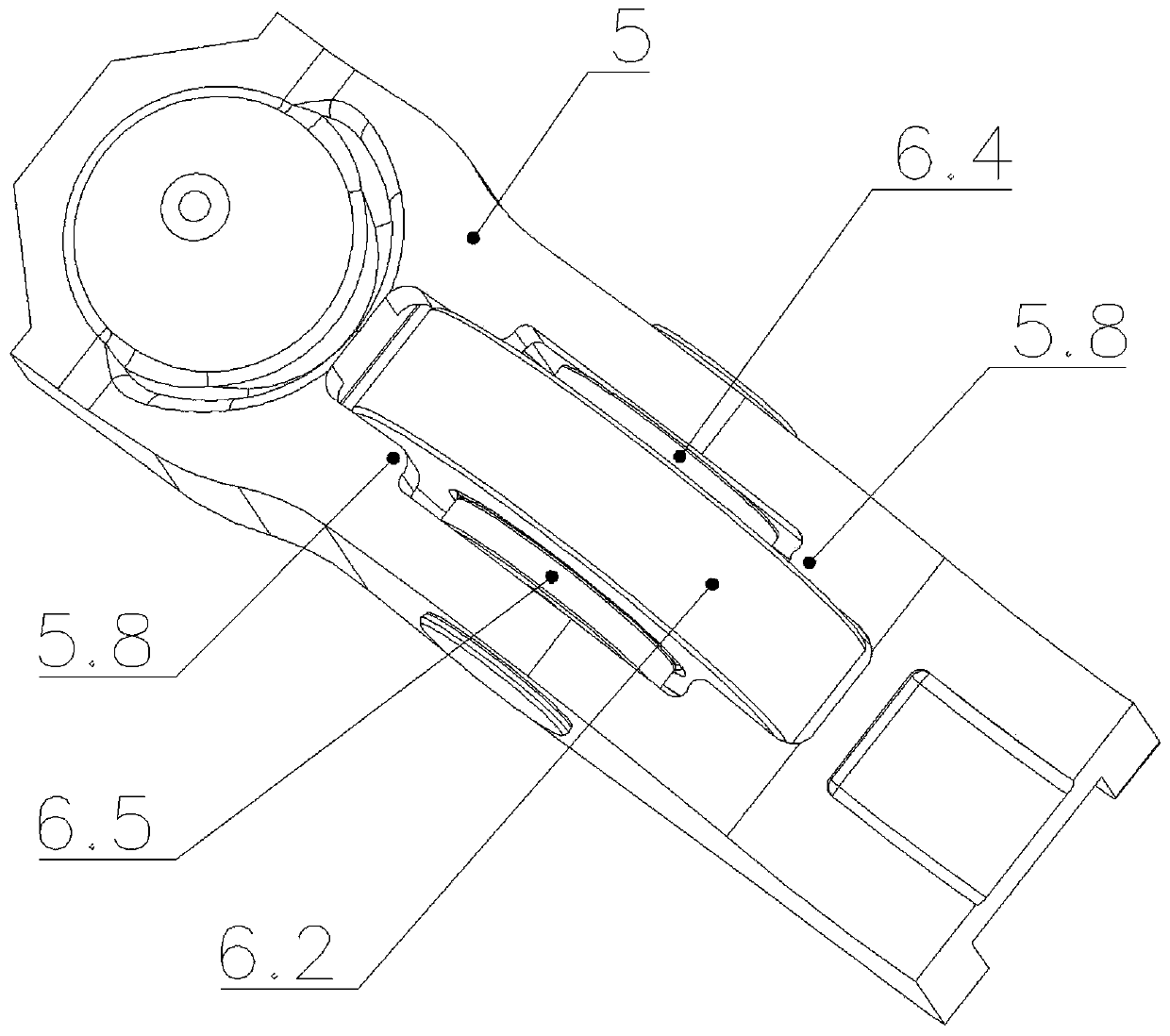

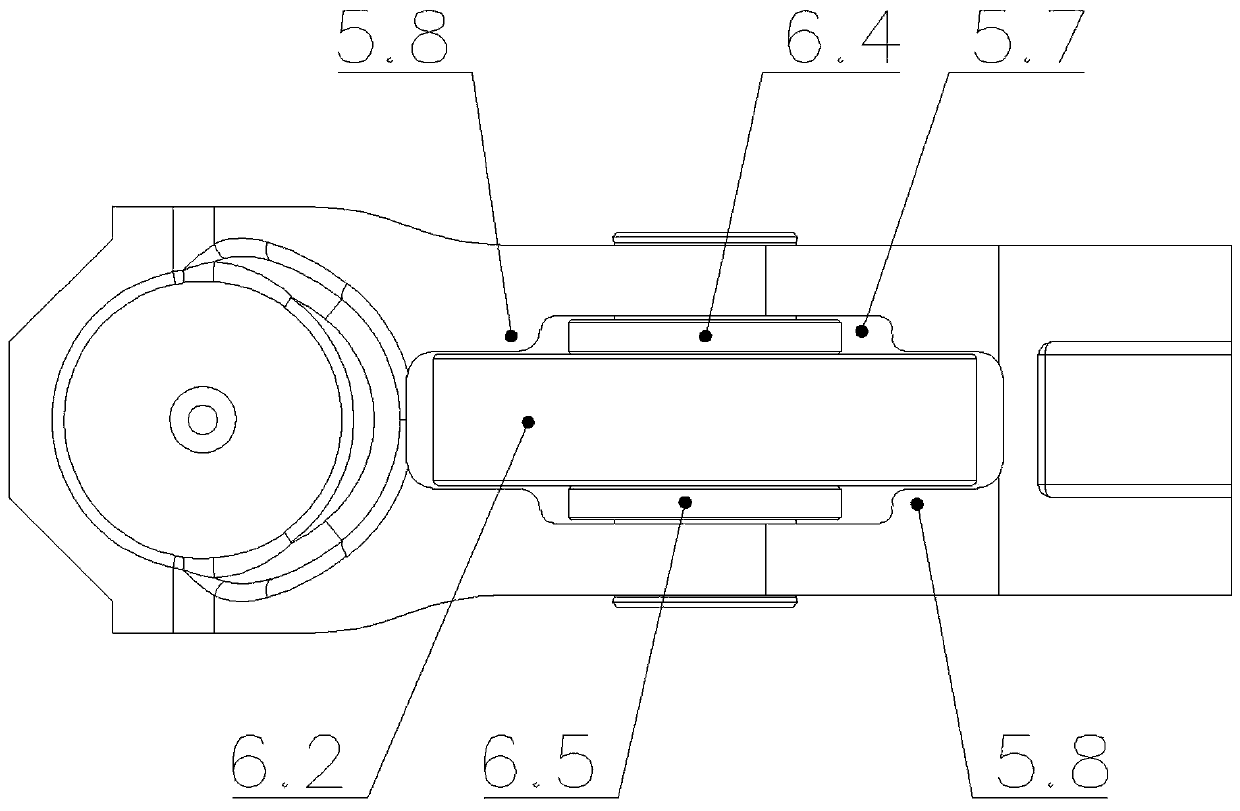

[0050] Embodiment 2: Combination Figure 7-11 As shown, the difference from Embodiment 1 is that the length of the needle roller 6.3 is greater than the width of the roller outer ring 6.2, and the retaining rings 6.4 and 6.5 are set on the needle roller 6.3. This embodiment does not need the step 5.8 structure, and the assembly hole 5.7 is integrated Square holes with the same width, retaining rings 6.4, 6.5 limit the axial movement of the roller outer ring 6.2, and the axial movement of the needle roller 6.3 is limited by the side walls 5.1, 5.2.

Embodiment 3

[0051] Example Three: Combining Figure 12-16 As shown, the difference from Embodiment 1 is that the retaining rings 6.4, 6.5 are set on the pin shaft 6.1, the length of the needle roller 6.3 is not greater than the width of the roller outer ring 6.2, and the outer diameter of the retaining rings 6.4, 6.5 is larger than the roller outer ring 6.2 In this embodiment, the step 5.8 structure is not required, the assembly hole 5.7 is a square hole with the same overall width, and the retaining rings 6.4 and 6.5 simultaneously limit the axial movement of the roller outer ring 6.2 and the needle roller 6.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com