Waste gas emission system for dual-fuel engine

A technology of exhaust gas emission system and dual-fuel engine, applied in the direction of engine components, machines/engines, exhaust devices, etc., capable of solving problems such as explosion, engine component damage, and damage to the exhaust system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

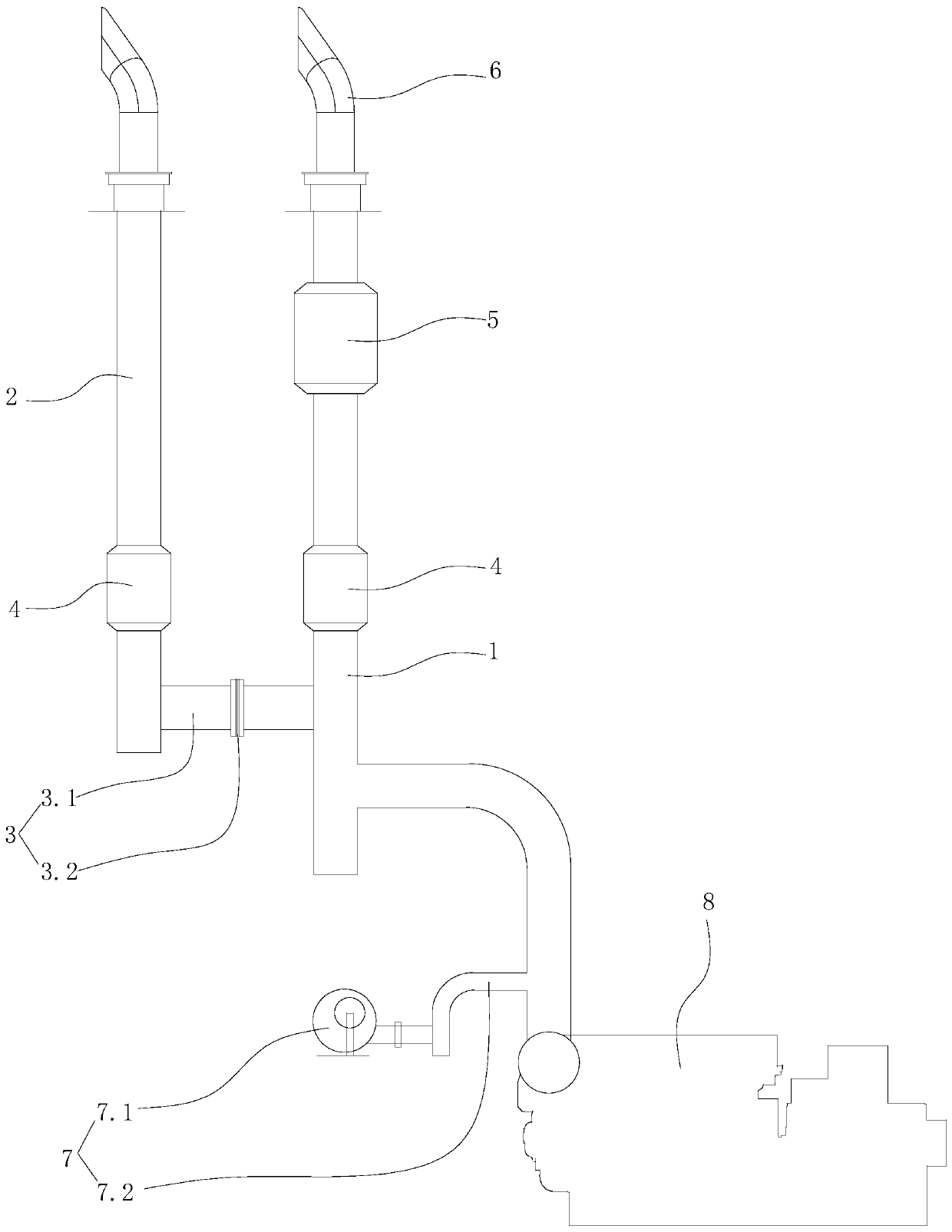

[0039] Specific embodiment one: such as figure 1 As shown, an exhaust gas exhaust system for a dual-fuel engine includes a main exhaust line, a backup exhaust line, and an explosion-proof connection device 3. The main exhaust line is used to discharge exhaust gas discharged from the operation of the engine, and the main exhaust line includes a main exhaust pipe 1 connected to the exhaust gas discharge port of the engine 8. The spare exhaust pipe includes a spare exhaust pipe 2, one end of the spare exhaust pipe is closed, and the other end of the spare exhaust pipe forms a spare exhaust port. The explosion-proof connecting device 3 includes an explosion-proof connecting pipe 3.1 connecting the main exhaust pipe and the backup exhaust pipe, and an explosion-proof protective sheet 3.2 for isolating the explosion-proof connecting pipe. The explosion-proof protective sheet cuts off the explosion-proof connecting pipe so that the main exhaust pipe and the spare exhaust pipe Trachea ...

specific Embodiment 2

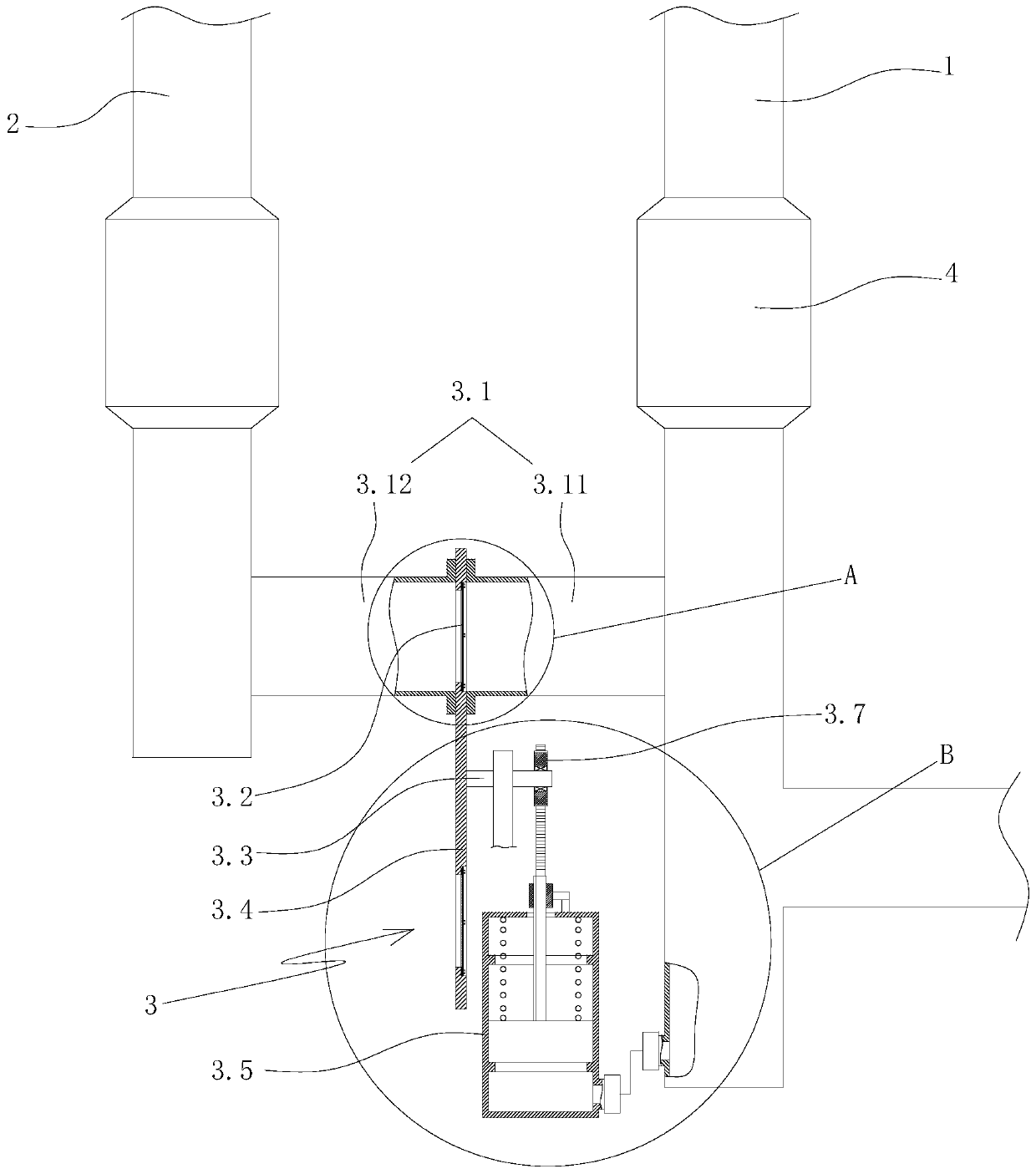

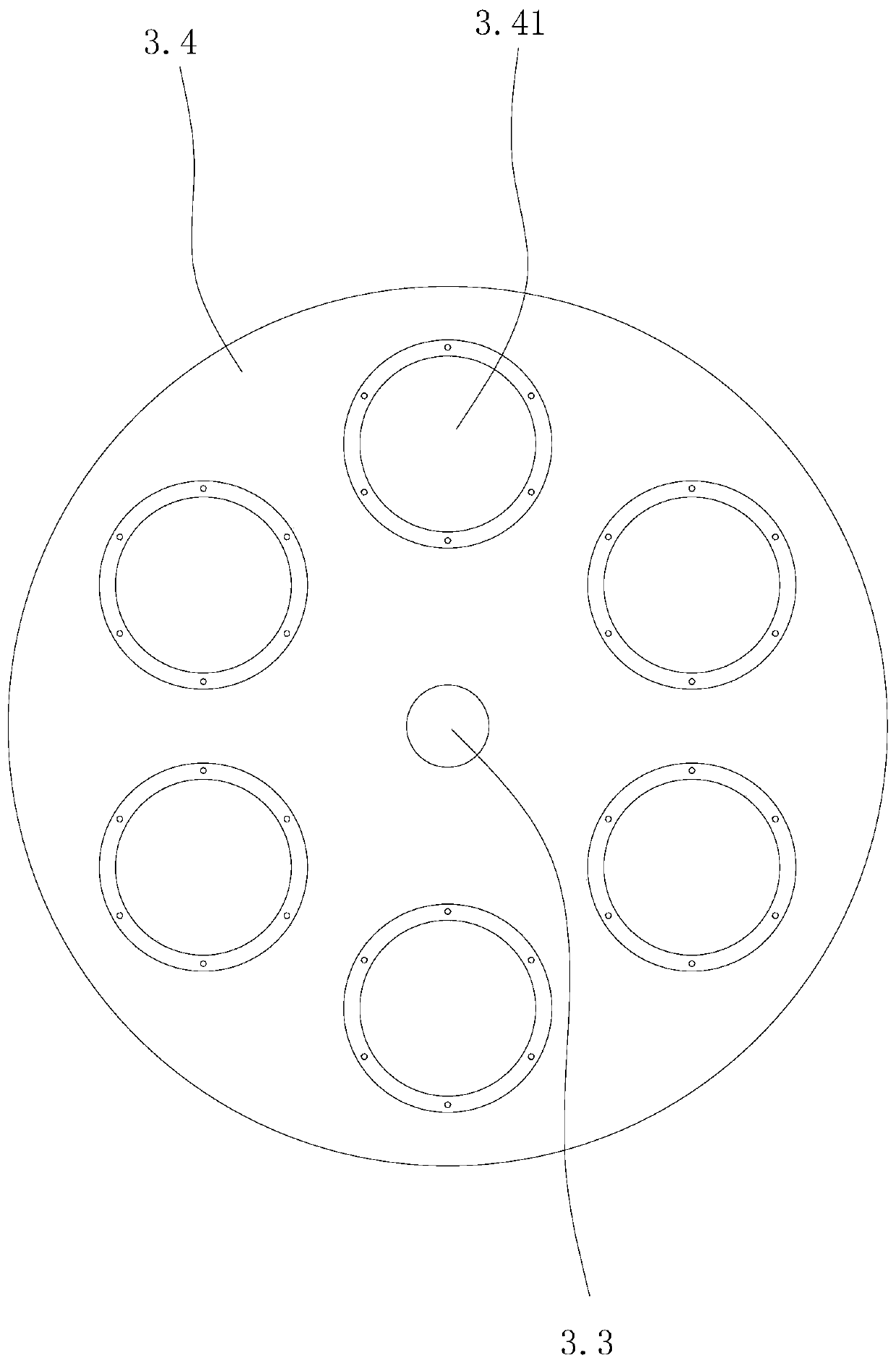

[0046] Specific embodiment 2: For the specific structure of this embodiment, refer to specific embodiment 1. The difference lies in: figure 2 , image 3 , Figure 4 , Figure 5 As shown, the explosion-proof connection device also includes a main shaft rod 3.3 arranged on the hull through a bearing rotation, an explosion-proof protection plate mounting plate 3.4 coaxially arranged on the main shaft rod, and N pieces of the explosion-proof protection plate installation plate evenly distributed around the shaft rod in the circumferential direction Explosion-proof protection plate mounting hole 3.41, drive gear 3.7 arranged on the spindle rod through a one-way bearing 3.6, rack gear 3.8 meshed with the drive gear, switching cylinder 3.5 arranged on the hull, arranged in the switching cylinder The first limiting block 3.51 and the second limiting block 3.52 on the side surface are slidably arranged in the switching cylinder and located between the first limiting block and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com