Double-screw-rod compressor radial bearing combination structure with sealing function

A technology of radial bearing and combined structure, which is applied to the sealing device of piston pump, the components of pumping device for elastic fluid, mechanical equipment, etc. The problem of high lubricant supply pressure has achieved the effect of widening the operating speed range, simplifying the system structure, and solving the problem of high lubricant supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

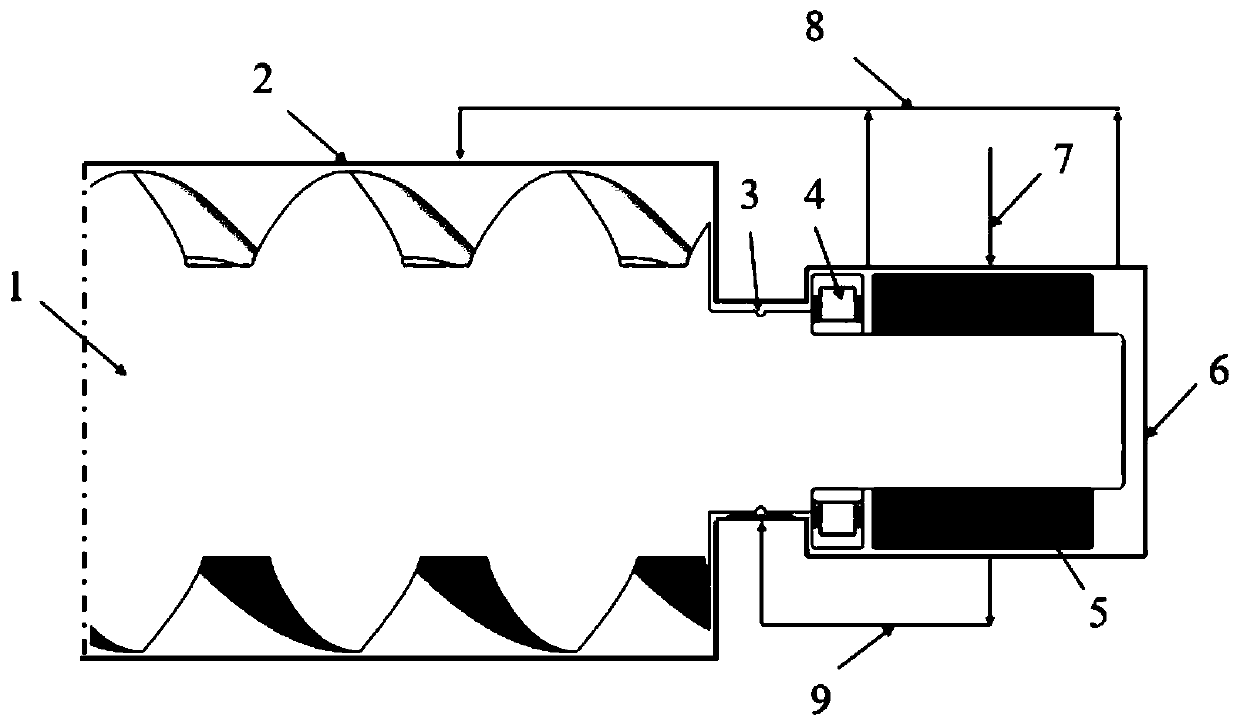

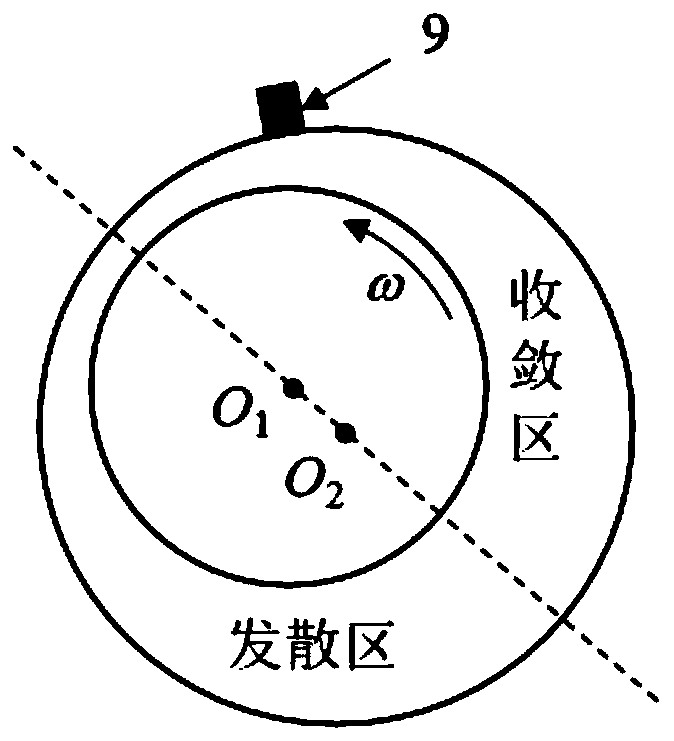

[0023] Take the bearing structure at the exhaust end of the male rotor as an example, such as figure 1 As shown, the radial bearing combination structure includes a radial dynamic pressure sliding bearing 5 and a rolling bearing 4 . The bearing bush at the middle position in the axial direction of the sliding bearing 5 is provided with an outflow hole, and the lubricant here can be led to the position of the shaft seal 3 through the sealant supply flow path 9, and can be used as a sealant to provide high sealing pressure and flow out. hole position as figure 2 As shown, it needs to be set in the convergent area of the gap during the operation of the sliding bearing 5, and the position is finally determined according to the required sealing pressure; in addition, the material of the sliding bearing 5 is ordinary materials, not expensive special materials that are resistant to wear, and when the lubricating medium (such as water, etc.) is corrosive, only need to spray corros...

Embodiment 2

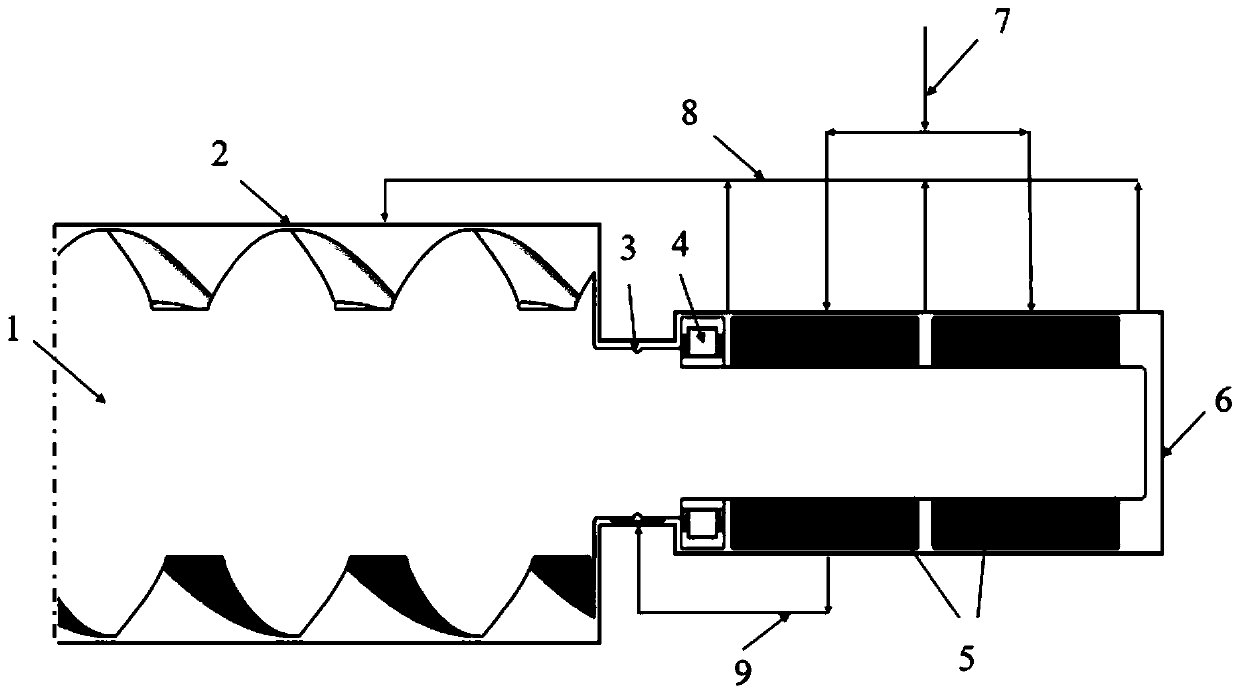

[0026] Such as image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that the number of sliding bearings 5 in the bearing combination structure is multiple (two are shown in the figure), so as to increase the bearing capacity of the sliding bearings and increase the corresponding lubricant supply flow Path 7 and lubricant return path 8.

Embodiment 3

[0028] Such as Figure 4 As shown, the difference between Embodiment 3 and Embodiment 2 is that a rolling bearing 4 is added on the side of the rotor shaft away from the rotor cavity, that is, the number of rolling bearings 4 in the bearing combination structure is 2, so as to avoid when there are too many sliding bearings 5 , The length of the rotor shaft is too long to cause the shaft to deform due to insufficient rigidity, so that the sliding bearing 5 and the wall surface of the bearing cavity 6 are rubbed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com