A kind of frd double seal real-time detection closed water socket joint

A socket joint, double seal technology, applied in the direction of engine sealing, sleeve/socket connection, pipe/pipe joint/pipe fitting, etc. problems, to reduce the impact, reduce maintenance time, and increase the space in the tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

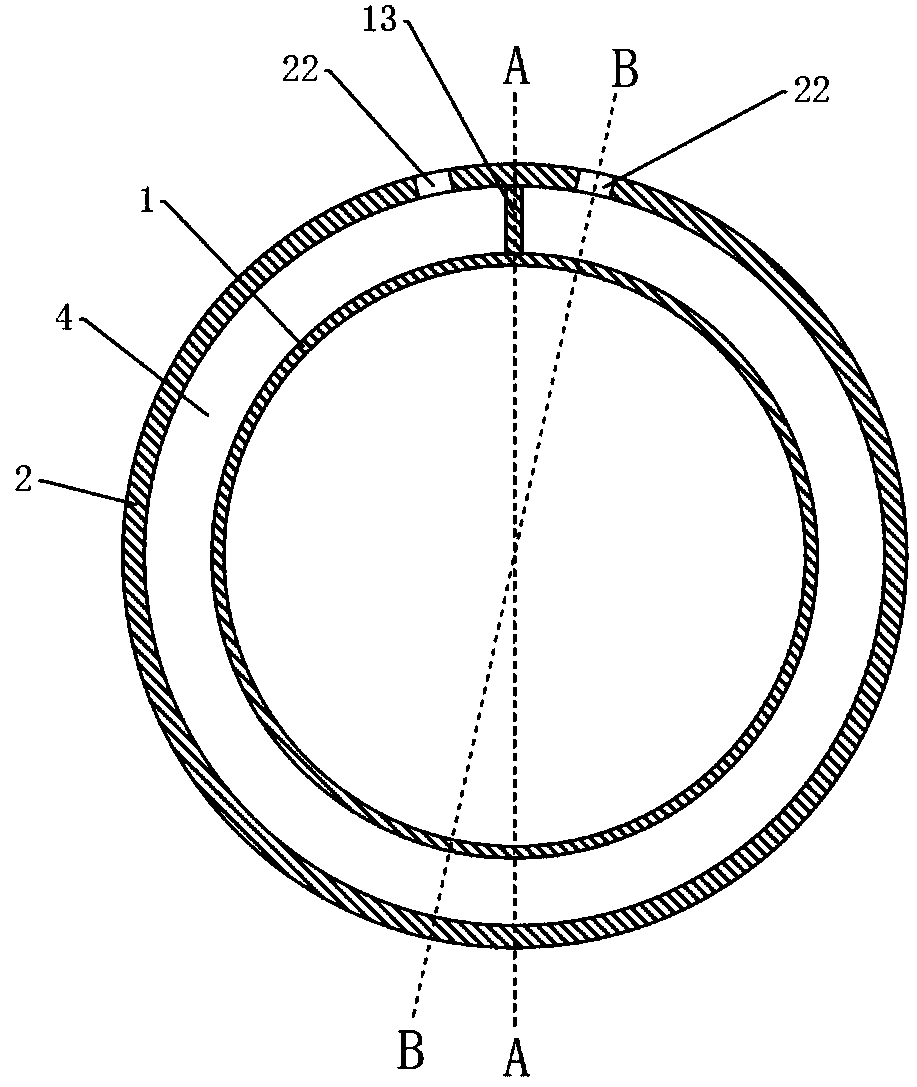

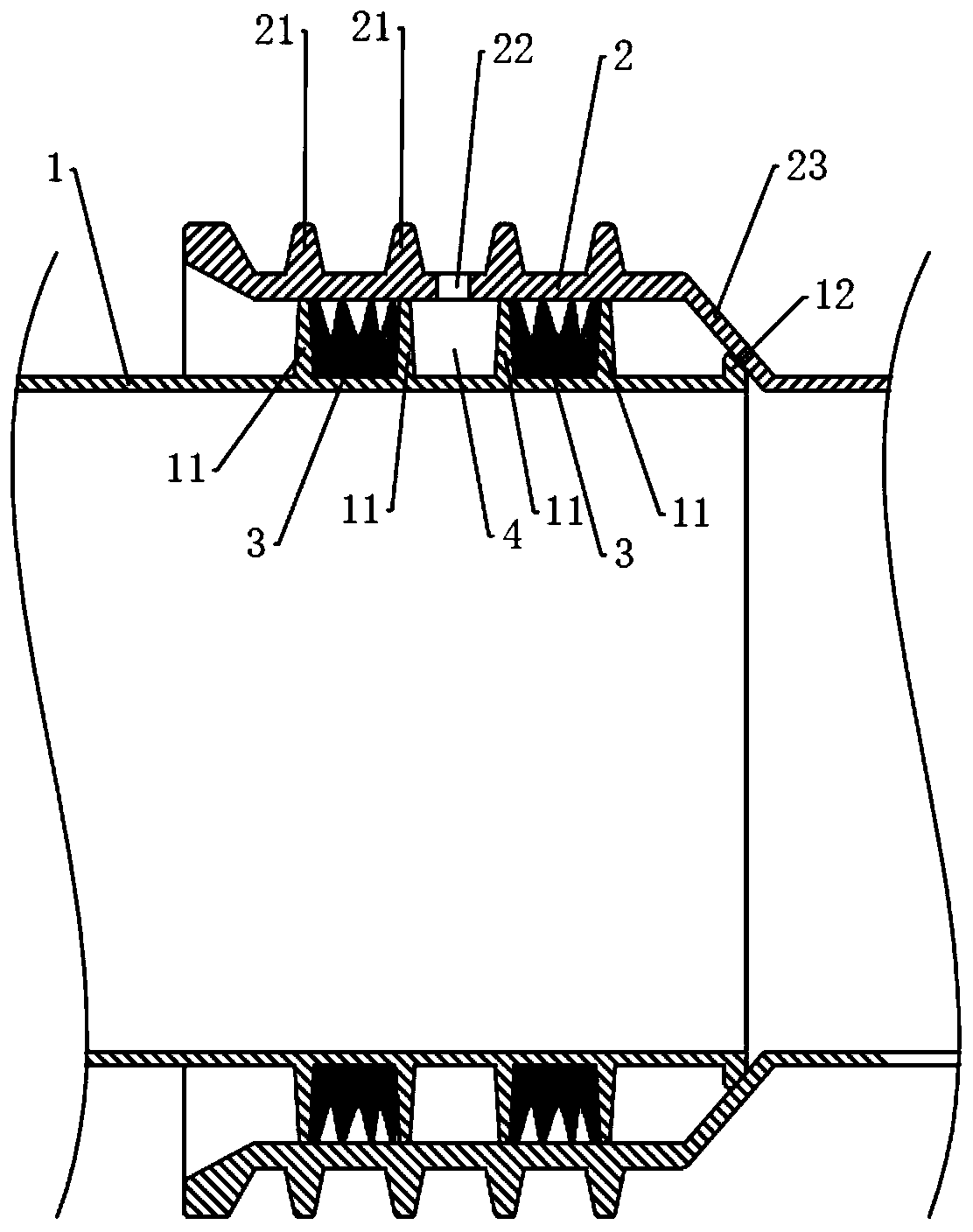

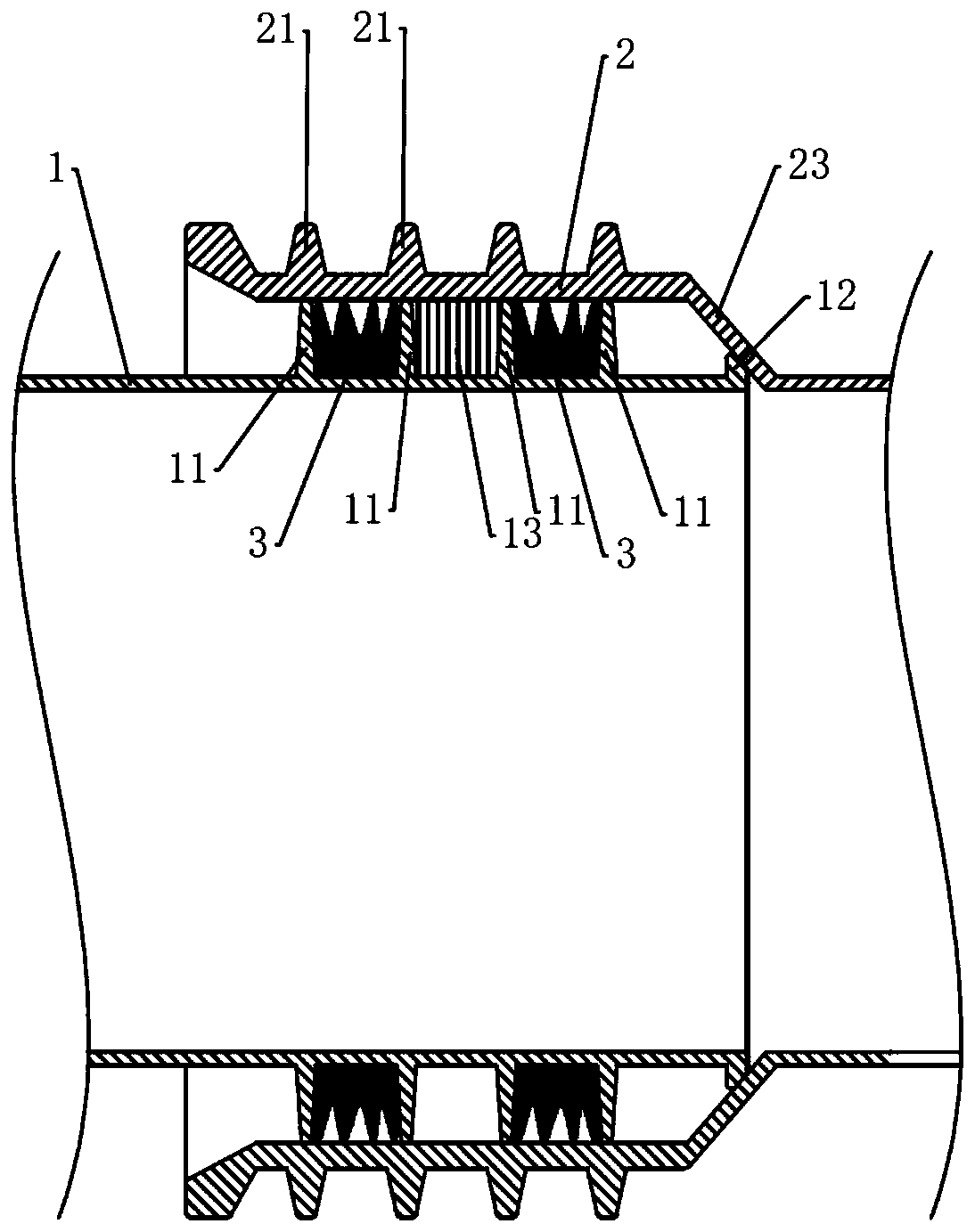

[0044] An FRD double-seal instant detection closed water socket joint, the socket joint in this embodiment is used for the connection of polyolefin plastic drainage pipes, including socket 1 and socket 2, and the socket 1 refers to the socket joint used in the socket joint For the inserted part, the socket 2 refers to the part used for socket in the socket joint. An annular pressure test groove 4 is provided on the outer wall of the socket 1, and an annular sealing ring installation groove is provided on both sides of the pressure test groove 4. In order to set the deep pressure test groove 4 and the sealing ring installation groove, the outer wall of the socket 1 is provided with four annular partitions 11 in parallel. Board 11 surrounds. Due to the fact that there are many specifications of drainage pipes, the outer diameter range of commonly used specifications includes 200-1200mm, corresponding to different outer diameters, the groove depth of the pressure test groove 4 a...

Embodiment 2

[0051] On the basis of Embodiment 1, in order to facilitate installation, one side of the socket 2 is provided with a plane support plate 6, and the structure of the plane support plate 6 is as follows Figure 8 as shown, Figure 8 The angle of view is slightly inclined toward the bottom of the plane support plate 6, the top of the plane support plate 6 is provided with an arc surface that matches the outer wall of the socket 2, and the top of the plane support plate 6 is also provided with a notch 61 for connecting with the socket 2. The reinforcing ring 21 on the outer wall cooperates. The bottom of the plane support plate 6 is provided with a plane. After the socket joint is installed, the plane support plate 6 is arranged at the lower end of the socket to support the ground, so that the positioning of the socket is more solid. In addition, the pressure test hole 22 is arranged on the upper end of the socket 2, which facilitates the operation of pressure test or injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com