Shunting device suitable for pressure welding pipe and wire jumper

A technology of shunt device and crimping tube, which is applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of dropped line accident, wire damage, heavy workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

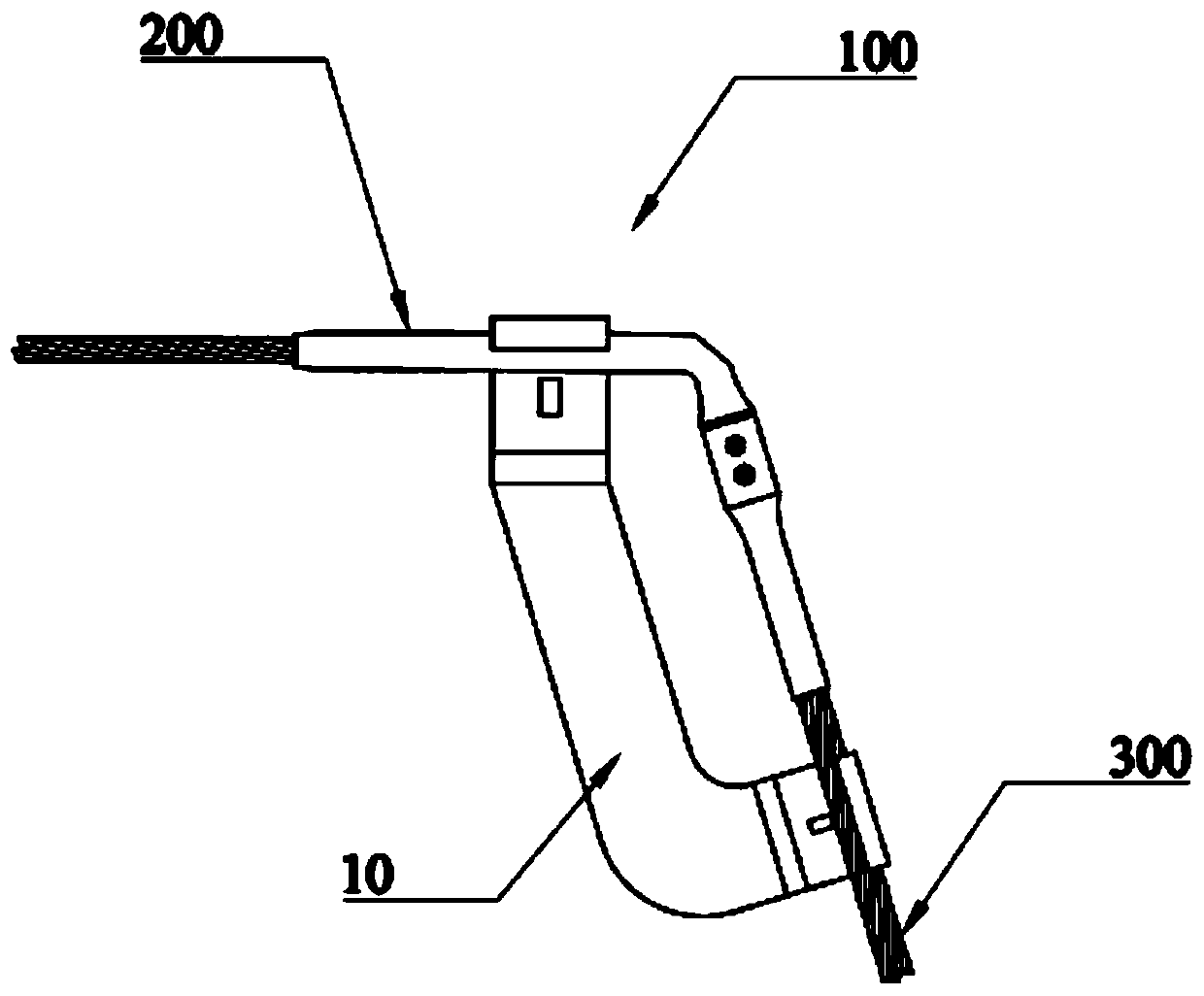

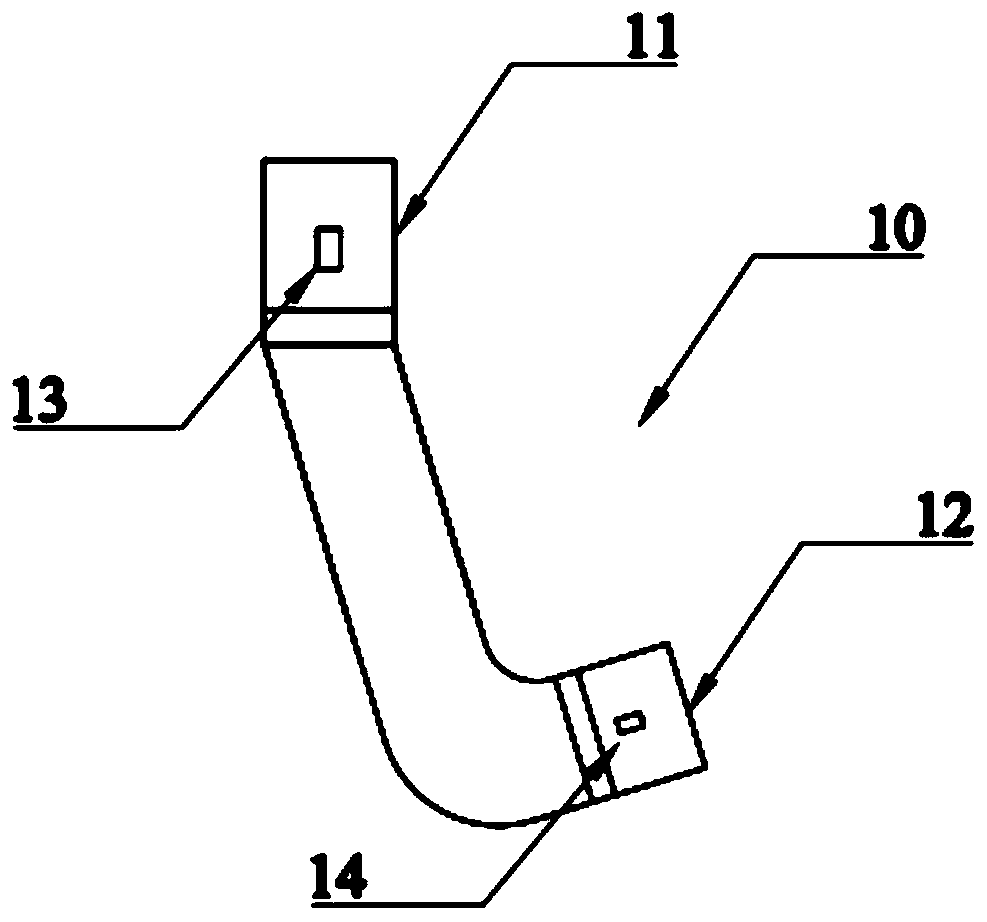

[0035] Such as Figure 1 to Figure 13 As shown, a distribution device 100 suitable for crimping tubes and jumpers includes: a distribution connection plate 10 , a first fixing component 20 and a second fixing component.

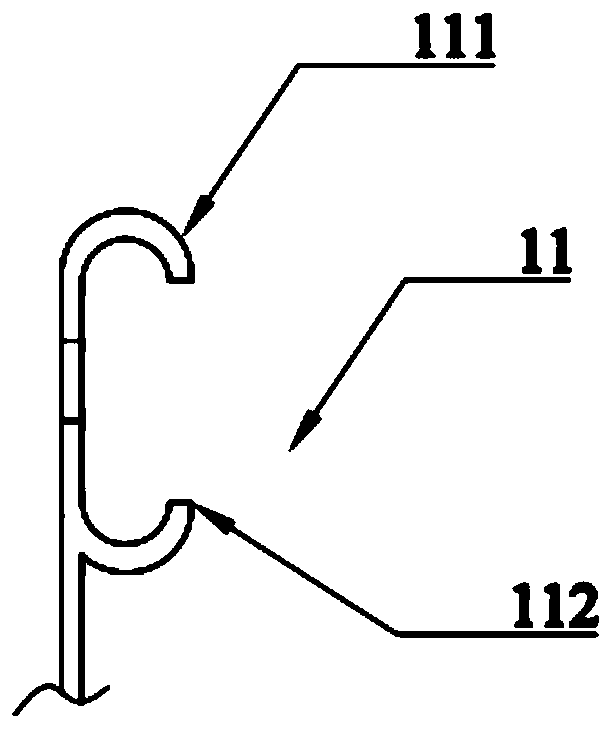

[0036] The distribution connecting plate 10 is provided with: a first connection structure 11 and a second connection structure 12 . The first connecting structure 11 is used to cooperate with the first fixing component 20 to fix the crimping tube 200 . The second connection structure 12 is used to cooperate with the second fixing component to fix the jumper 300 .

[0037] Specifically, the distribution connecting plate 10 is processed by an integral aluminum alloy with high flow guiding performance. The distribution connecting plate 10 is respectively fixed on the non-pressing area and the jumper of the strain-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com