Motor shell

A technology for motor casings and casings, which is applied in the direction of casings/covers/supports, electrical components, electromechanical devices, etc., can solve problems such as noise that cannot be solved, and achieve rationalized noise reduction effects, reduced noise, and reduced friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

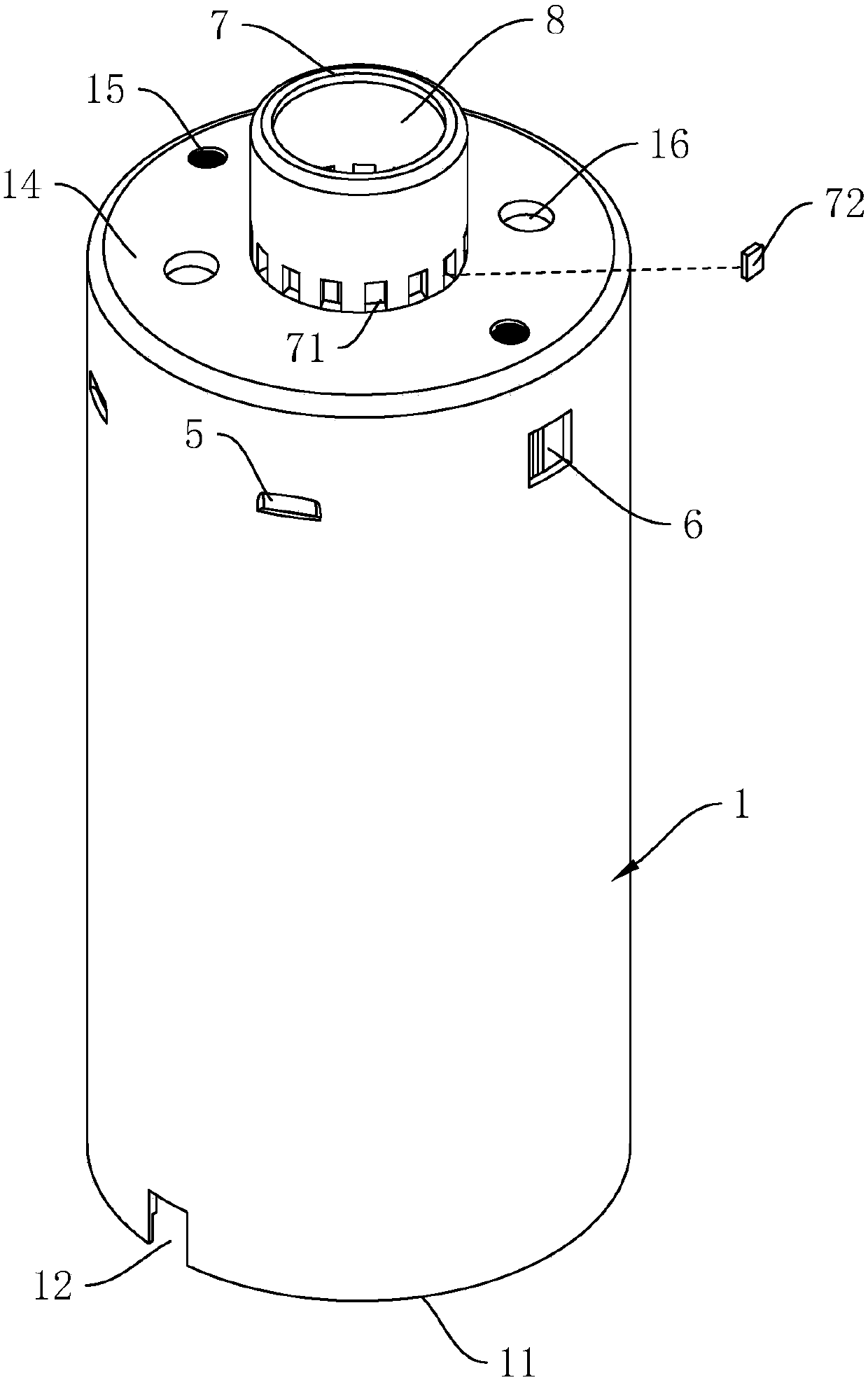

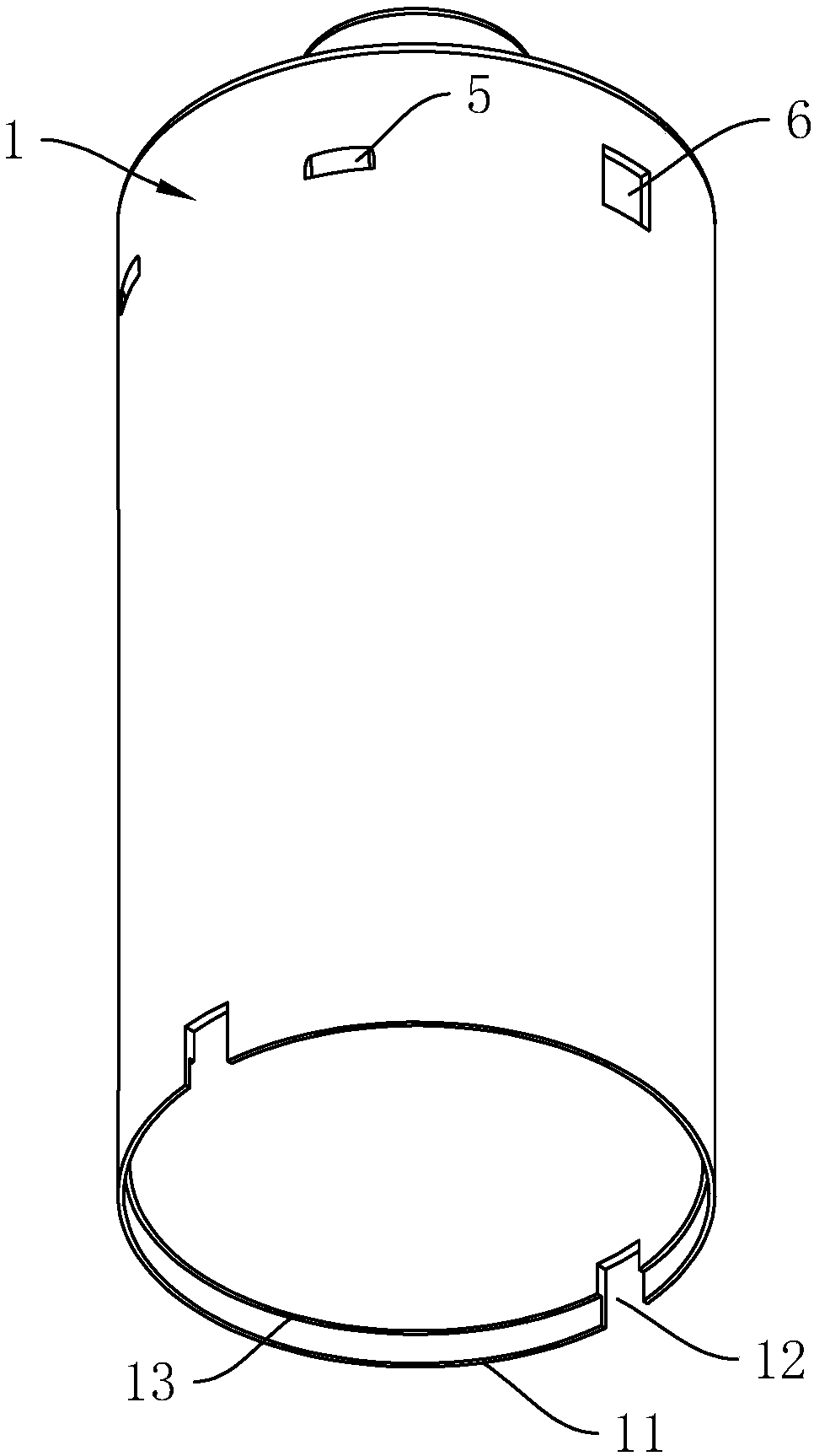

[0033] Embodiment one: if figure 1 and figure 2 As shown, a motor housing includes a housing body 1, and the housing body 1 is generally made of stamping and deep drawing. A stator, a rotor, a shaft and a bearing are installed in the housing body 1, and the stator is fixed on the housing On the side wall of the body 1 , the shaft passes through both ends of the housing body 1 . One end of the housing body 1 is an opening 11, and the opening 11 is used for fixing the end cover. The side wall of the housing body 1 is symmetrically provided with square slots 12, and the slots 12 are arranged at the opening 11. The slots 12 are convenient for quick positioning of the end cover and prevent the end cover from rotating. The inner diameter of the side wall of the housing body 1 at the slot 12 is reduced to form a step 13, which is used for interference fit with the fixed end of the end cover, so as to realize the fixation.

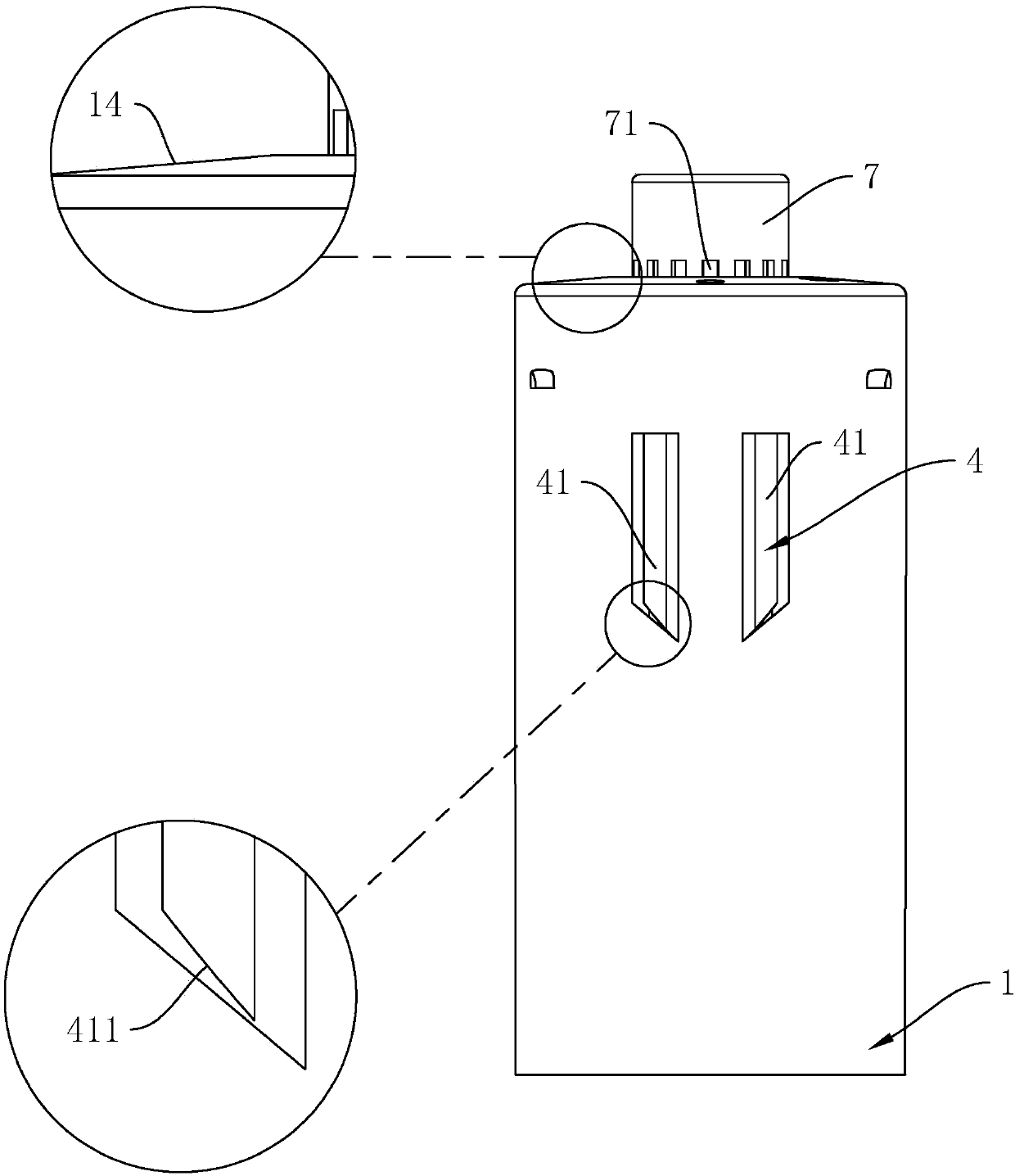

[0034] refer to image 3 combine figure 1 and figure...

Embodiment 2

[0040] Embodiment two: if Figure 4 and Figure 5 As shown, the difference from Embodiment 1 is that, on the outside of the side wall of the motor casing body 1, the punch is squeezed into the side wall, forcing the outer wall of the casing body 1 to form several grooves 2, and the casing The inner wall of the body body 1 forms corresponding ribs, the groove 2 is a strip groove arranged in the axial direction, and the length of the groove 2 is smaller than the length of the side wall of the housing body 1, and the two adjacent grooves 2 are in the horizontal direction. If they are set at a certain interval, there is a slideway 21 between two adjacent raised ribs. A sound-absorbing block 3 is arranged in each groove 2, and the sound-absorbing block 3 is made of rubber, elastic plastic, polyester fiber or soft foam plastic, and the size of the sound-absorbing block 3 is slightly larger than the groove 2, so that the sound-absorbing block 3 Interference fit with the groove 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com