Solar power generation system with automatic snow and dust removal function

A technology of power generation system and solar energy, applied in the field of solar power generation system, can solve the problems such as the influence of the output performance of the solar panel, the large amount of labor for removing the snow from the solar panel, and the reduction of the battery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

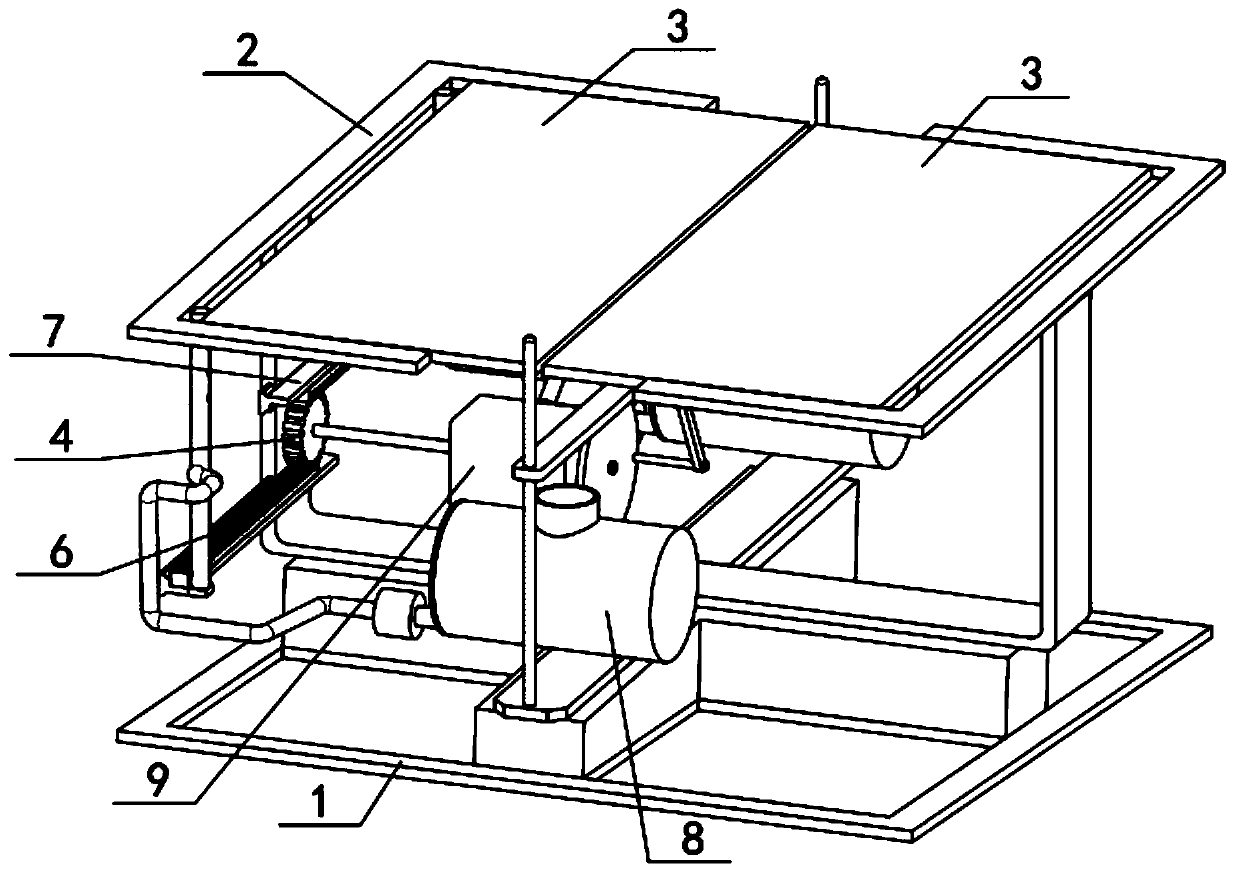

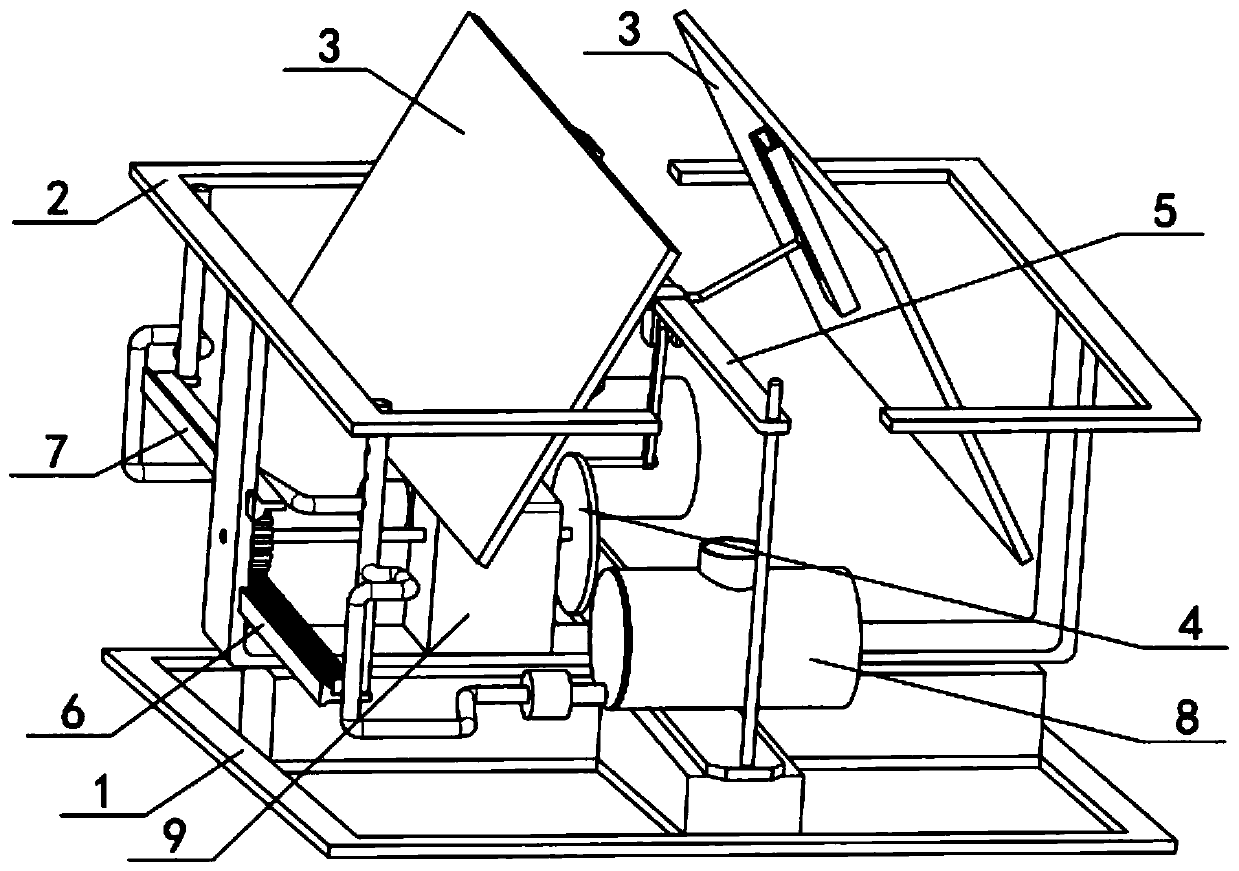

[0030] Such as Figure 1-10 As shown, the solar power generation system for automatic snow removal and dust removal includes a slope frame 1, a main frame 2, a solar panel 3, a brake mechanism 4, an adjustment structure 5, ash removal module I6, ash removal module II7 and a water supply module 8. The slope The main frame 2 is fixedly connected to the frame 1, two solar panels 3 are rotatably connected to the main frame 2, the brake mechanism 4 is fixedly connected to the main frame 2, the adjustment structure 5 is connected to the brake mechanism 4 in rotation, and the adjustment structure 5 The left and right ends are rollingly connected with two solar panels 3 respectively, the front and rear ends of the adjustment structure 5 are slidingly connected to the main frame 2, the ash removal module I6 and the ash removal module II7 are both engaged with the brake mechanism 4 for transmission, and the ash removal module Both the I6 and the ash removal module II7 are slidingly conn...

specific Embodiment approach 2

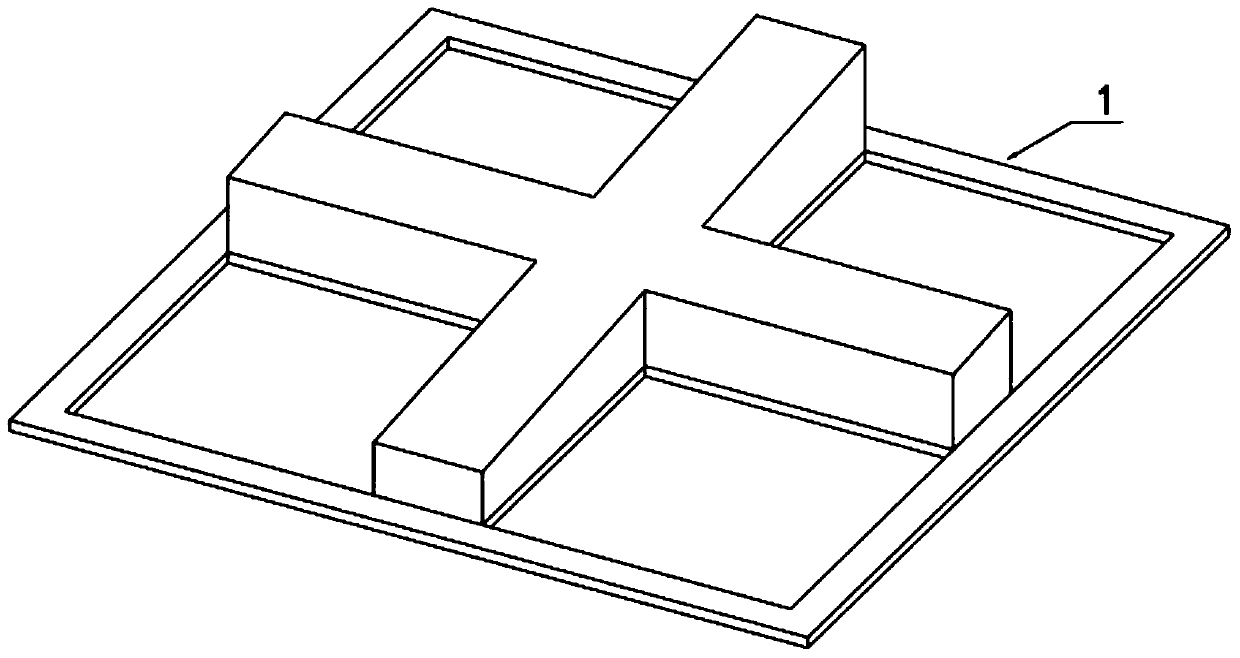

[0031] Such as Figure 1-10 As shown, the main frame 2 includes a cross base 2-1, a motor base 2-2, a guide rod 2-3, a top frame 2-4, a support shaft 2-5, a linear slideway 2-6 and a shaft hole I2 -7, the left side of the cross base 2-1 is fixedly connected with a motor base 2-2, the front and rear sides of the cross base 2-1 are fixedly connected with guide rods 2-3, and the two sides of the upper end of the cross base 2-1 Both are fixedly connected with a top frame 2-4, and the two top frames 2-4 are fixedly connected with a support shaft 2-5, and the inner side of the left end of the cross base 2-1 is provided with two linear slideways 2-6 and a shaft for The hole I2-7, the shaft hole I2-7 is located in the middle of the two linear slides 2-6; the cross base 2-1 is fixedly connected to the upper end of the inclined plane frame 1. The guide rod 2-3 is used to make the adjustment structure 5 more stable when it moves up and down.

specific Embodiment approach 3

[0032] Such as Figure 1-10As shown, the solar panel 3 includes a panel main body 3-1, a shaft hole II 3-2, a slide rail 3-3, a groove 3-4 for rollers and a strip opening 3-5, and the panel main body 3-1 The middle end is provided with a shaft hole II 3-2, and the lower end surface on the right side of the panel main body 3-1 is fixedly connected with a slide rail 3-3, and the slide rail 3-3 is provided with a groove 3-4 for rollers and a strip opening 3- 5. There are two solar panels 3; the two solar panels 3 are mirror images, and the two panel main bodies 3-1 are connected to the two supporting shafts 2-5 through the shaft holes II 3-2 respectively. superior. The panel main body 3-1 is a photovoltaic panel, i.e. a solar cell panel. If the shaft hole II 3-2 is inconvenient to be arranged on the panel main body 3-1, the slat structure can be fixed at the middle side of the lower end of the panel main body 3-1, and the The shaft hole II 3-2 can be set on the slat structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com