Tubular oil-gas separator and oil-gas separation method

An oil-gas separator and tube-type technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as high cost, high investment, and troublesome operation and management, and achieve small footprint and overcome large volume , to reduce the effect of pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

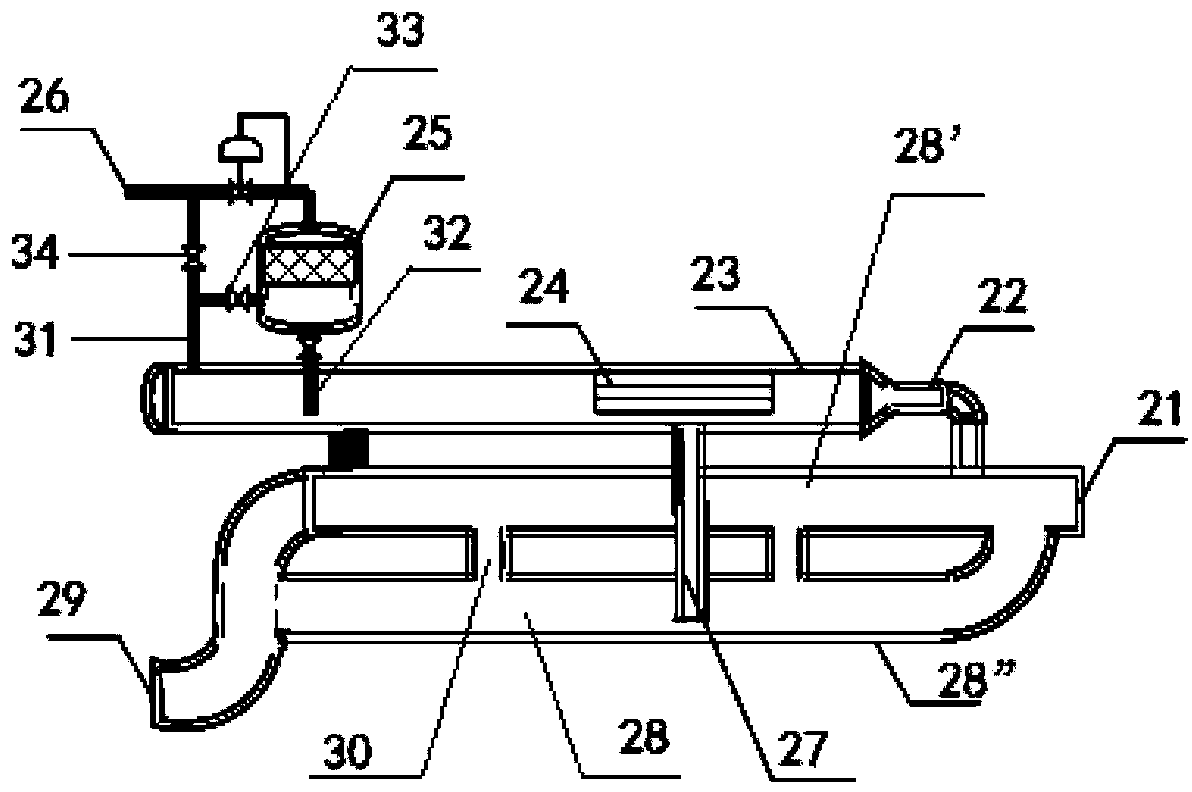

[0029] In order to make the technical solution of the present invention clearer, a specific introduction will be made below in conjunction with the accompanying drawings.

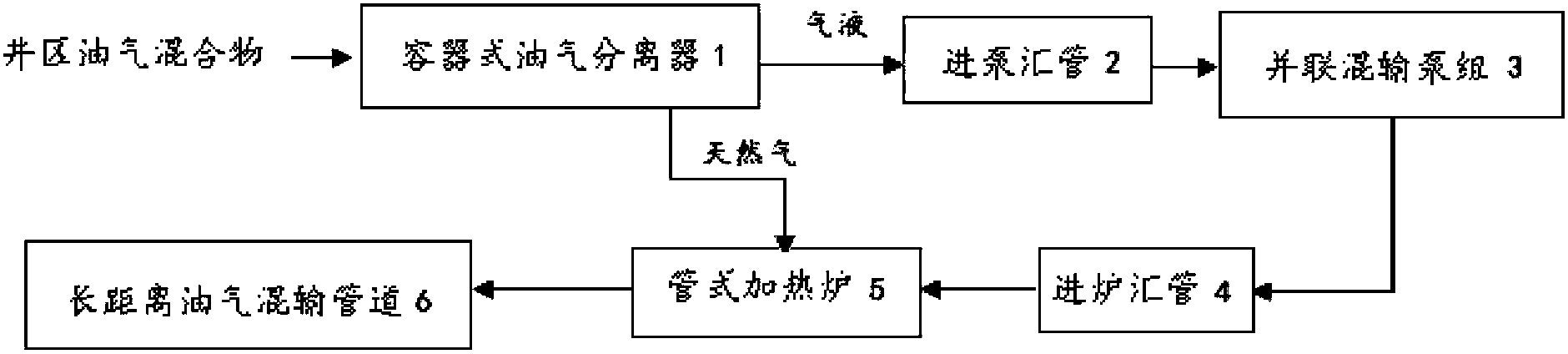

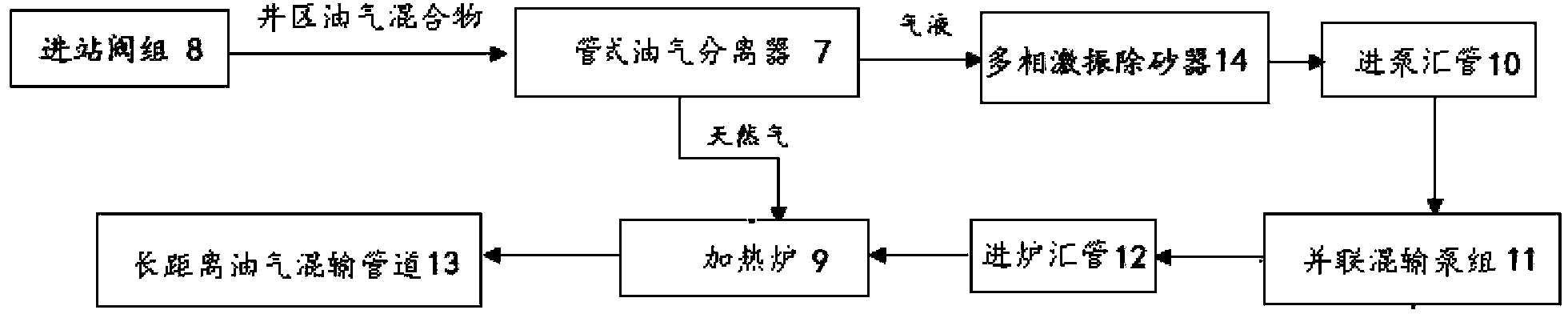

[0030] The oil-gas separator is the key supporting equipment in the oil-gas mixed transportation system, such as figure 1 In the shown oil-gas mixed transportation system, a container-type oil-gas separator 1 is used. The present invention designs a pipe-type oil-gas separator 7, which can replace the container-type oil-gas separator 1 for figure 1 The system shown can also be used for figure 2 The oil-gas mixed transportation system shown. figure 2 In the oil-gas mixed transportation system shown, the inlet end of the pipe-type oil-gas separator 7 is connected to the manifold after the inlet valve group 8 to receive the oil-gas mixture, and part of the natural gas is separated from the oil-gas mixture as the fuel for the heating furnace 9 The 7 outlet ends of the tubular oil-gas separator are divided i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com