Rock debris treatment type mud tank capable of flexibly changing cleaning position

A processing type, mud tank technology, applied in the direction of mixer with rotating stirring device, chemical/physical process, dissolution, etc., can solve the problem of debris accumulation and blockage, inconvenient cleaning, etc., to achieve the effect of avoiding blockage and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

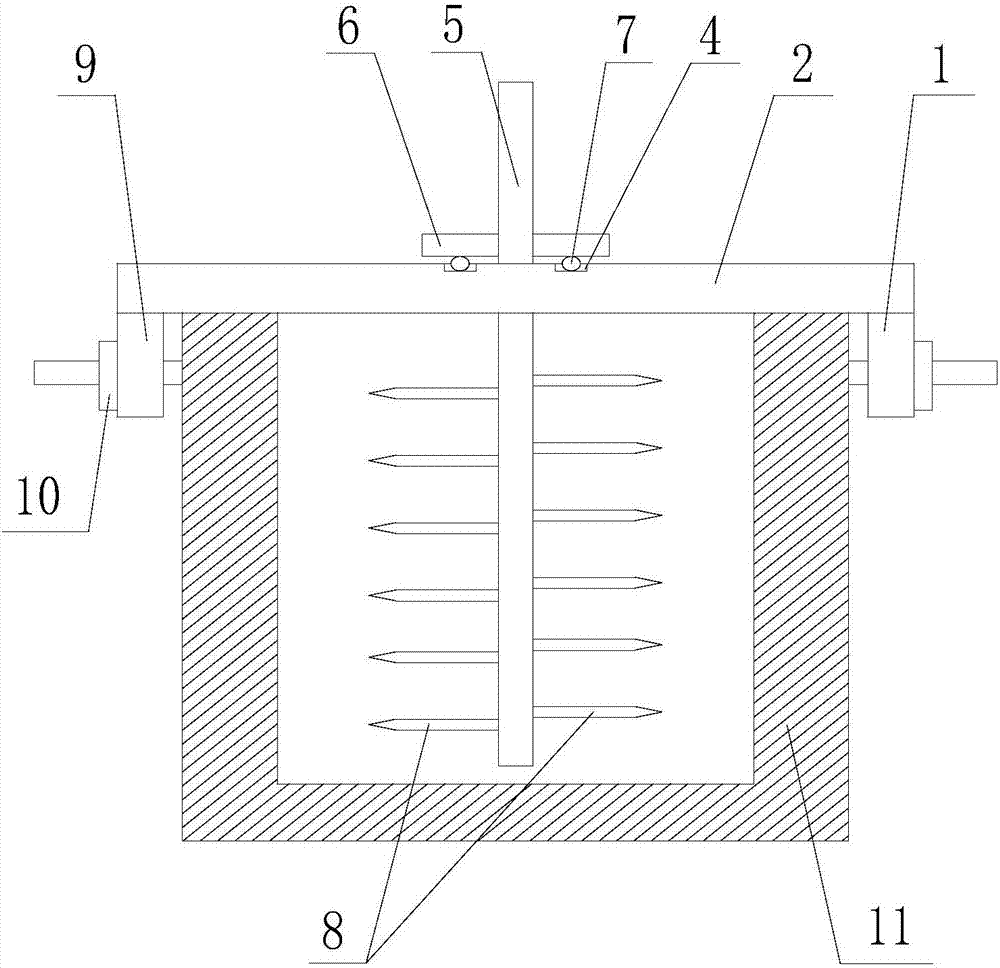

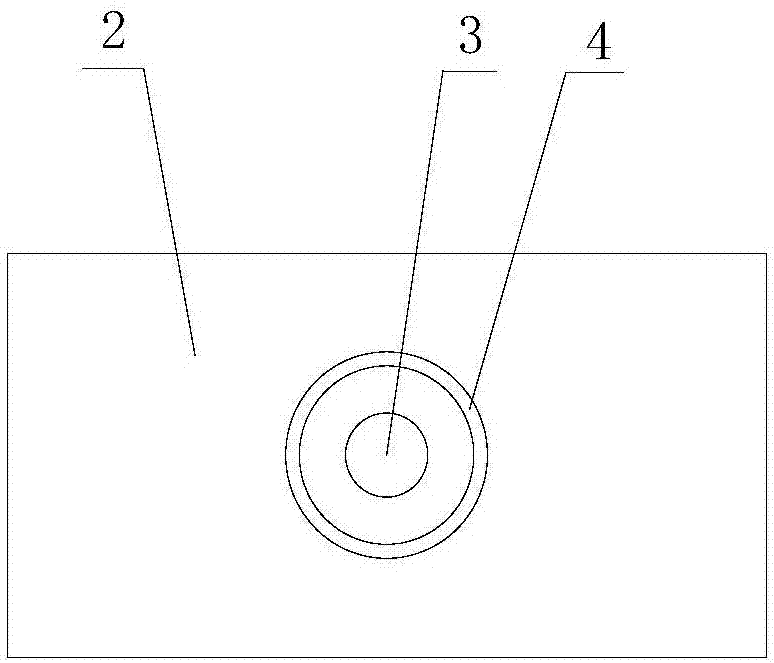

[0021] Such as figure 1 and figure 2 The cuttings treatment type mud tank for flexibly changing the cleaning position as shown is characterized in that it includes a straight plate 2, the opposite ends of the straight plate 2 are respectively fixedly connected with a baffle plate 1, and the center of the straight plate 2 is provided with a circular through hole 3 and a circular An annular groove 4, the groove 4 is concentric with the through hole 3, and the through hole 3 is located inside the ring of the groove 4; also includes a stirring rod 5 passing through the through hole 3; the stirring rod 5 The upper cover is provided with a disc-shaped turntable 6, and the turntable 6 is fixedly connected to the stirring rod 5; the surfaces on both sides of the turntable 6 are perpendicular to the axis of the stirring rod 5, and the surface of the turntable 6 is provided with N rollers 7, N rollers 7 rings are evenly distributed, the turntable 6 is located on the side of the straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com