High-speed magnetic suspension air blower electrically-controlled element radiating system

A heat dissipation system and blower technology, applied in the direction of cooling/ventilation/heating transformation, cabinet/cabinet/drawer components, etc., can solve the problems of increasing the power consumption of the whole machine, reducing work efficiency, and inconvenience, etc., to achieve Improved stability, improved operating efficiency, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

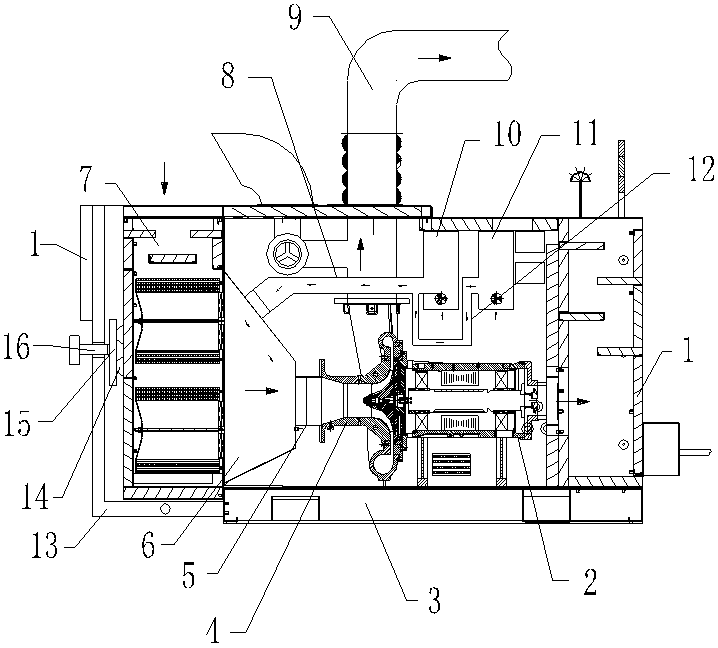

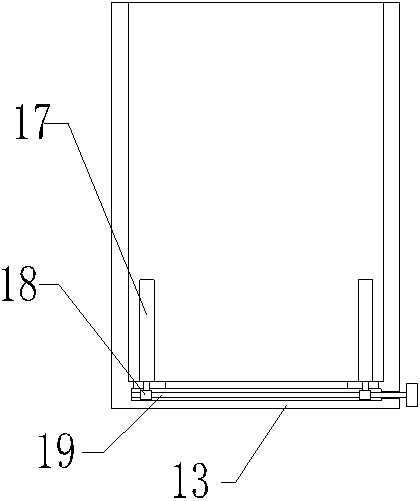

[0017] see figure 1 and figure 2 , the present invention provides a technical solution: high-speed maglev blower electric control original heat dissipation system, including sound insulation cover 1, blower 2, base 3, current collector 4, intake pressure resistant silicone expansion joint 5, flow guide cone 6 , air filter 7, heat dissipation pipe network 8, user pipe network 9, magnetic bearing controller 10, motor controller 11 and conduit 12, the sound insulation cover 1 is fixed on the upper end of the base 3, and the blower 2 is fixed on the sound insulation cover 1 by screws Inside, the current collector 4 is fixed on the left end of the blower 2, the flow guide cone 6 is fixed on the left part of the sound insulation cover 1, and the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com